Heat pipes - features and scope

For the most efficient transfer of energy from the coolant to the consumer, heat pipes are used. They allow you to transport different types of coolant with the lowest temperature loss. In this article, we take a closer look at the features of these devices and their area of application.

Features of the heat pipe

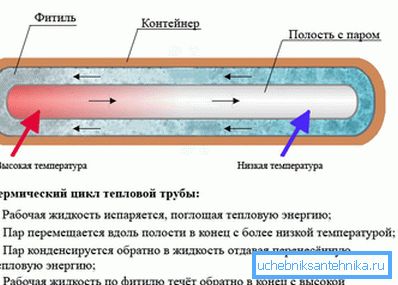

Operating principle

The principle of operation of heat pipes is that energy transfer occurs due to evaporation and further condensation of the liquid. To understand how this happens in practice, it is necessary to imagine a closed container made of a metal with good thermal conductivity and filled with some water.

The heat transfer processes in it are as follows:

- When heating one part of the tank, the water in it will turn into steam.

- Leaving the liquid, the water vapor falls on the cooled surface, as a result of which the vapor again changes to a liquid state and flows back to its original place.. In this case, a large amount of thermal energy is discharged through the walls of the metal reservoir.

- The cooled water is heated again and the process repeats..

This design is called a thermosyphon. Although it is not a heat pipe, however, the principle of operation is the same.

Note! Thermosiphon can work as it should be only if its condensation zone is located above the evaporation zone. This ensures the return of condensate to the place of heating.

Grover Heat Pipe

The simplest design of a heat pipe is as follows:

| Housing | Must be made of a material that conducts heat well. In addition, an important requirement for the body is its strength, so that it can provide reliable tightness. As a material for it, various alloys of various metals are usually used, as well as ceramics or glass for pipes. The type of case may depend on the type of case. |

| Workspace | It is a liquid substance (coolant), capable of at a working temperature to move into a gaseous state. |

| Wick | Solid material with pores through which the liquid through the capillaries moves from one part of the pipe to another. |

The above device is called the Grover heat pipe. This scientist in 1963 improved the design of a thermosyphon in which liquid flowed by gravity. In Grover's heat pipe, the fluid is moved in a capillary manner.

In order for this system to function, the following requirements are put forward to the working fluid:

- The liquid-vapor transition point must be in the temperature range in which the device operates.

- The liquid should not undergo thermal decomposition.

- The wick material and pipe body should be wetted with liquid.

Various fluids can be used as working fluids in the liquid phase:

- Ammonia;

- Liquefied helium;

- Acetone;

- Water;

- Mercury;

- Silver;

- Sodium.

As for the wick, then, as mentioned above, this element provides the movement of fluid under the action of capillary forces. The main requirement for this material - ensuring uniform movement of the working fluid through the capillaries.

Most often used as a wick:

- Metal mesh;

- Metal felts;

- Metal stacks;

- Twill weaving fabrics, etc.

At first glance it may seem that this device is quite simple, however, its technical calculation can be performed only by specialists. The fact is that for its effective work it is necessary to choose the right material, its performance and size. Therefore, it is unlikely that you will be able to perform heat pipes with your own hands, but a heat siphon can be done independently.

The transfer of heat energy in such devices can be done in several ways:

- Using an open flame;

- In direct contact with the heated substance;

- Electric current;

- Infrared radiation.

Note! The only value limiting the thermal capacity of the device is the thermal resistance of its body.

I must say that the functions of Grover's heat pipes are quite diverse, but their main task is to transfer thermal energy from one part of the pipe to another. As for the temperature of the working environment, the instructions for their use allows a range from zero degrees Celsius to thousands of degrees.

Contoured heat pipes

With the development of technology, Grover’s heat pipes have been improved - special contour tubes have replaced the wick.

The advantage of this design is:

- Reliability in work;

- Simplicity;

- Higher level of heat transfer;

- Good adaptation to different operating conditions;

- Durability;

- The performance characteristics are preserved at any spatial position, due to which such a heat pipe is installed with your own hands without any difficulties.

In fact, the contours are the same capillaries, but have large sizes. As a result of their qualities regarding heat transfer, the tubes are superconductors of thermal energy.

The scope of modern heat pipes

The scope of application of heat pipes is quite extensive:

- Heat transfer with minimal costs to various objects and buildings.

- Many cooling systems, including refrigerators, are made on the basis of heat pipes.

- Heat removal in various microelectronic devices, in particular, heat pipes are often used in PCs.

- The medicine.

- Space industry.

- A complete set of thermostats and other devices similar in purpose.

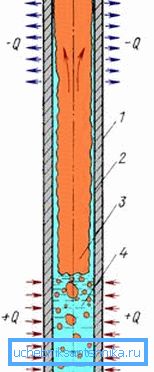

- Construction in permafrost conditions.

- In agriculture, while ensuring the warmth of greenhouses, etc.

- This device is a required part of thermal switches and diodes.

- It can also be used heat pipe for heating residential and industrial premises.

I must say that the characteristics of modern heat pipes are quite impressive:

| Operating temperature range | From 4 to 2300 K |

| Heat transfer power | Up to 20 kW per square centimeter |

| Work resource | More than 20 thousand hours. |

Here, perhaps, all the main points that you can briefly talk about heat pipes. (See also the article Distribution of heating pipes: features.)

Conclusion

From the video in this article, you can get more information on this topic. We also note that heat pipes are widely used in modern manufacturing, heating systems and many other industries. This is due to the design features of products that provide efficient transportation of working fluids, with high efficiency.