Heated water pipes as a way to protect the system and ensure

Sometimes it is impractical to lay communications below the level of soil freezing because of the time-consuming process of work and high costs. It is much easier and more reliable to make the electric heating of water pipes, in this case, you will not be left without water supply even with the greatest frost and guaranteed to protect the system from damage. It is important to choose the best option and pave it correctly, this is what this article will be about.

The main advantages of heating systems

Many developers mistakenly believe that heating elements are necessary to defrost communications in the winter. In fact, they prevent freezing, preventing deformation of the elements, and still have a number of undeniable advantages:

| Simplify workflow | Due to the fact that the depth of laying communications can be much less, excavation work is significantly reduced, which significantly reduces and costs. As a result, even taking into account the cost of heating elements, the total price of the project remains almost unchanged, which is important in a number of cases. |

| Optimum working conditions | This factor is especially important in cases when liquids with high viscosity (oils, various solutions and compositions) are transported through pipelines. Maintaining the required temperature conditions ensures optimal system performance under any external conditions. |

| Maintaining the desired temperature | If the system is heated during operation, it is possible to significantly reduce heat loss during transportation. That is, the cost of heating is compensated by reducing energy consumption. |

| Easy do-it-yourself installation | In order to carry out the work, you will not need to purchase complex and expensive equipment. In addition, the installation instructions are very simple, do not need special knowledge and skills, it is important to follow the recommendations and be careful, special attention should be paid to the joints |

| Maintainability | In case of unforeseen situations and accidents, the work on troubleshooting is much faster and simpler, since the depth of laying communications is much less |

The main methods of heating pipes

There are several options that are used to create such systems, consider the most popular of them, well-proven in the operation.

Heating cable outside the pipe

This option refers to the most budget and simple to implement, so this method is used most often. Its essence is simple: a heating wire is laid along the pipe, which prevents freezing and undercooling of the system.

This method has a number of features:

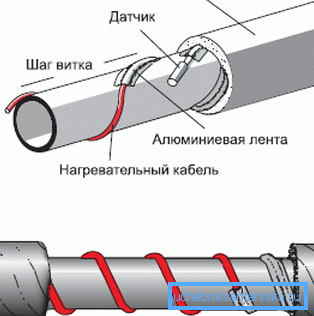

- The cable can be laid both along the pipe and in waves or in the form of a spiral.. Spiral winding significantly increases material consumption, but heating is more uniform and very efficient.

- First, all the necessary information is calculated: the depth of the gasket, the climatic features of your region, the diameter of the pipe and the features of the system. On this depends on the choice of cable for its capacity and method of installation.

- Next, the heating wire is attached in accordance with the winding option you choose., so that it remains stationary, it is best to fix it with ordinary adhesive tape.

- The next important stage of work is wrapping the pipe with foil., This greatly improves the heat transfer of the cable and reduces heat loss, which ultimately leads to energy savings and increase system efficiency without additional costs.

- It is very important to properly heat the pipeline in order to minimize heat loss.. Insulation can significantly reduce the time of the heating elements, because with it communications are protected from the cold much better.

- In order to protect the insulation and the wire from deformation, it is best to additionally protect the system with a metal pipe (more often take corrugated sleeves). You can also use other methods: bandage, trays and more.

Self-regulating cable

This option is very similar to the above in terms of installation.

But he has a whole lot of undeniable merits:

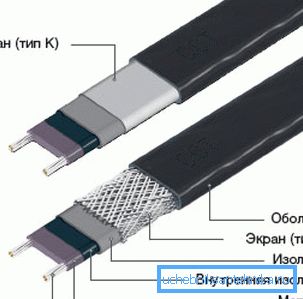

- The principle of operation is based on the use of a special semiconductive matrix, which reacts to a change in the temperature of the pipe and turns on only when the temperature drops below an acceptable level.

Note! The greatest advantage of this solution is the fact that the cable can heat different parts of the pipe with different intensity, that is, the colder places are heated more intensively, the warmer places less intensively. This saves a significant amount of energy.

- The installation process is much simpler, since control units and other regulatory nodes are excluded from the system. The wire connects to the supply cable and to ensure the tightness of the connection is protected by a shrink tube.

- Unlike conventional cable, self-regulating can intersect with each other, it is absolutely safe and allowed by the regulations.

- Despite the higher cost, this option pays off in full during the operation. In addition, its use is much easier, because the system can operate in a completely autonomous mode.

Note! A more advanced and efficient option is the use of a heating tape, it resembles a cable, but, by contrast, has a much larger width, which greatly increases the efficiency of work with similar energy consumption.

Heating pipes from the inside

Heated plumbing inside the pipe is used less often, but this option is also worth considering, because it has a number of advantages:

- Due to the location of the heating element directly in the system, the efficiency of its work is significantly increased, because energy is not spent on heating the walls of pipes.

- If necessary, the cable can be introduced into any straight section of the pipeline, while its bending and passing through the fittings for connecting pipes in any case are not allowed.

- To insert a wire into the system, a tie-in is made on the pipe or a tee is put in and a special pipe insert is screwed in. Through it, a heater is inserted and fixed by means of the fastening element, which is supplied.

- This option can be used as needed, that is, to include in the network only when the temperature drops to a dangerous level. The system is compact, and it can be purchased in finished form at plumbing stores, the main thing is to find the right length.

It is worth noting that the cable is available in a polyethylene sheath, absolutely harmless to humans, which is why such heating can be done in drinking pipelines. It is important to remember that the minimum permissible internal diameter of pipes should not be less than 20 mm.

Conclusion

Whichever option you choose, it is important to carefully follow all recommendations of the instructions and to prevent disruption of the process. The video in this article will explain some important aspects of this issue in more detail and in detail.