Heating cable for sewage and plumbing: heating methods and

In cases where the owners simply do not have the opportunity to lay pipes above the level of soil freezing, there is an urgent need to organize heating of sewage pipes from the inside or outside in the winter season.

Of course, it is more expedient to lay the pipeline nevertheless below this level, but if there are circumstances that do not allow this, then by all means it is necessary to use additional heating elements.

Types of pipes that need heating

Often it is necessary to warm sewer pipes of the following types:

- External sewer pipe used to drain sewage into a septic tank or to a local-type treatment plant:

- Pipes used to drain flushing water from filter-cleaners;

- A pipeline that provides communication between the sewer septic tank and drainage fields or filtration well.

Pipeline heating methods

The most popular and frequently used methods of heating sewage are the following:

- Heated sewer system with heating wire;

- Pipeline laying of elements equipped with its own heating system inside the pipe.

Heating sewage with cable

During the search for the answer to the question of how to heat the sewage system in a private house, each owner wants to use the most reliable and durable heating element, which is a self-regulating cable, operating on the principle of heating tape.

The peculiarities of using this method include:

- The power of this type of heater is about 33 W per 1 meter of pipe;

- At its laying the reinforcing tape with an aluminum dusting on a sticky basis is used;

- You can cut it into pieces of any desired length;

- If the length of the pipeline in need of heating is less than 80 meters, then a cable of that length can be plugged directly into a power outlet or into an electrical panel without additional devices.

Council This type of heater is not recommended for creating internal heating. Internal gasket can only be a temporary measure in case of emergency.

Connection process

Instructions for connecting the heating cable with your own hands consists of the following steps:

- A heat shrinkable tube of large diameter is put on one of the ends of the heating cable;

- The end is stripped of insulation and for a length of about 5 cm, the braid is removed for a length of 1 cm;

- The wires of the heating cable are separated and removed from their ends insulation of a length of 4 cm;

- On the cable itself they put on a heat-shrinkable tube of medium size, and also shrink tubes of small diameter are put on each wire;

- Holding the shrink tube with tweezers, we warm it with a building dryer;

Council If the building hair dryer was not at hand, you can shrink using an open flame. For example, the usual lighter.

- We clean the ends of the wires to 0.6 cm;

- The twisted braid is placed in a metal tube, after which we clamp it;

- We make stripping of the electrical cable from insulation for a length of 8 cm;

- We separate the wires of the electrical cable. Ground wire leave the same length the rest is cut off by 3-4 cm;

- We clean each wire of food on 6 cm;

- We make connection of wires of electric cable and heating:

Council This connection is recommended using a heat shrink tube with a metal sleeve in the middle.

- After connection, the sleeve is clamped, and the tube is seated with a hairdryer;

- The places where the power wires are connected must be insulated with insulating tape;

- We make the connection of the metal braid, place its end into the metal sleeve, after connecting the sleeve must be clamped;

- The junction of the braid must be insulated with electrical tape;

- The junction is covered with a large-diameter shrink tube, which then sits with a hair dryer;

- The free end of the heating cable is stripped 0.6 cm, the metal braid is removed;

- A heat-shrinkable cap is put on the end of the cable and shrinks also with a hair dryer.

Installation of the heating element

For high-quality system operation, it is necessary to ensure not only the connection, the cable for heating the sewage pipes must also be correctly installed.

The process of fixing the heating element to the pipeline should be conducted with the following requirements:

- The bend radius must exceed the minimum allowable value specified in the instructions for each type of cable;

- Do not install this element on sharp surfaces;

- Before installation, you must ensure the tightness of the pipeline;

- Do not connect a coiled cable to the network;

- After the installation of the heating element, it is necessary to insulate the sewer pipe.

Installation process

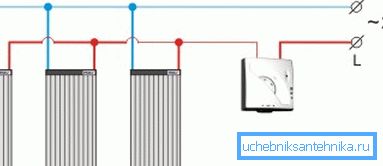

Today it is possible to use one of the 2 installation options:

- The location of one or more heating elements along the pipe parallel to each other. The price of the heating system in this case directly depends on how many heating elements will be used;

- Winding of the pipeline as a spiral.

Note! The second type of installation is used in the case when the cable length is several times the length of the pipeline.

The installation itself is carried out as follows:

- For uniform heating of plastic pipes, it is recommended to pre-wrap them with foil on a sticky basis;

- The heating element is also attached with foil tape;

Note! Whatever method of fasteners you choose, remember that the suppression of a resistive heater is simply unacceptable.

- Thermal insulation of the pipeline is made in such a way as to exclude the ingress of moisture. If necessary, wrap the pipes with additional waterproofing material;

- Thermal sensor is attached to the pipe with a foil scotch tape.

Finally

Implementing all the tips, recommendations and instructions described above, you will be able to provide your own sewer system with adequate heating, and the pipes will not freeze even in the most severe frosts. And the video in this article will tell you even more about how to protect the sewer pipeline from winter frosts.