Hot-rolled pipe - the perfect solution in difficult

This product is used in all areas of construction. Hot-rolled pipe according to GOST 8732 78 should not have seams, which gives it tremendous strength. We will tell you about this material below.

General information

When creating them, special rolling units are used. So that you can understand their features, we will provide a full range of information.

Merits

Hot-rolled seamless pipe has a huge number of advantages, thanks to which it deserved wide recognition.

Let's get acquainted with them:

- Highest reliability. Due to the absence of seams, the probability of occurrence of leaks is reduced to nothing.

- Creation technology ensures durability.

- Colossal resistance to all types of mechanical loads.

- Resistance to many aggressive agents (even to corrosion).

- Wide operating temperature range.

Despite the increased popularity of various products for the sewage system made of plastic, such pipes remain among the leaders on the market. This is due to the fact that only such a material can provide similar strength. In many areas this property comes to the fore.

disadvantages

Of course, this material has some negative properties.

To form the most complete opinion, they should also be aware of:

- Great weight (however, this property has the majority of metal products). Because of this, it is difficult to work with them with your own hands. There is a need to use specialized equipment.

- Perhaps the main drawback is the high price. It is connected with a complex production technology.

Scope of application

As mentioned earlier, the product described by us is used in many areas.

Therefore, we will list them:

- Organization of pipelines, both in residential and in industrial construction. The fact that they are not afraid of water, in many ways contributed to this.

- Avia-, auto- and tractor construction.

- Oil industry.

- Transportation of any liquids. Here the lack of seams comes to the fore, giving one hundred percent protection against leaks.

- Shipbuilding.

- Laying of sewage and drainage systems from pipes. If you decide to create such a system with your own hands, we recommend using the seamless materials described by us. Such a measure will provide virtually unlimited service life.

Specific samples and their approximate prices

Anyone who is thinking about purchasing such material wants to know how much it costs. Therefore, we decided to provide you with such data, taking the most recognized varieties and the average price for the leading enterprises of our country.

| The size | Average cost (per ton), rub. |

| 57 x 3.5 | 51000 - 51500 |

| 57x4 | 51500 - 52000 |

| 76x4 | 5200 |

| 89x4 | 49500-50000 |

| 89x6 | 50000-50500 |

| 108x4 | 50000-50500 |

| 108 x 4 | 50,000 |

| 108 x 5 | |

| 108 x 6 | |

| 114 x 5 | |

| 127 x 5 | |

| 133 x 5 | |

| 159 x 5 | |

| 159 x 6 | |

| 168 x 6 | 38000-39000 |

| 168 x 7 | 38500-39000 |

| 168 x 8 | 39000-39200 |

| 219 x 6 | 57500-58000 |

| 219 x 7 | 52000-52500 |

The difference in prices due to different production technology. Where it is more difficult, naturally, cost increases. However, as you can see, the difference is not so significant, so it is recommended to make a choice on specific tasks.

Tip: buying a large quantity at once will save you a substantial amount (most organizations have favorable offers for wholesalers). Therefore, if possible, cooperate with someone to get a discount.

It is also worth noting that the prices at all large enterprises of our country are approximately the same, for the production methods and raw materials are identical. For this reason, if you find a product whose price is significantly lower, most likely it means only one thing - it is not made according to the standard, and therefore is not of the best quality.

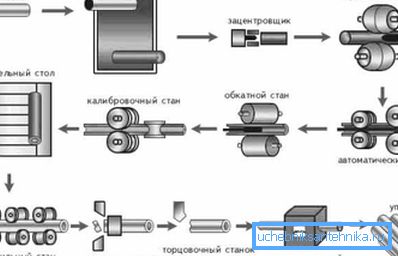

Production features

As we said earlier, strict control is exercised over the manufacture of such products. If even the slightest defect is detected, the billet is sent to the smelter, where it easily finds a second life. This technology allows you to repeatedly melt the workpiece to obtain the desired quality.

If the product turned out good quality, then it is sent for inspection. It is the most important aspect.

In general, each blank is checked for:

- Stretching.

- Exposure sulfide corrosive cracking.

- Hardness.

- Hydro resistance.

Only if each test gave a positive result, the resulting product is sent to the warehouse for further use.

Classification according to GOST

Steel seamless hot-rolled pipes according to GOST 8732 78 have several possible classifications. Let's look at them:

By manufacturing accuracy:

- Standard.

- Improved (P).

- Highest accuracy (B).

By section type:

- Square.

- Round.

- Rectangular.

Note! The tolerance in length is 10 mm, so if you are offered a product with a larger error, it can be argued that it does not meet the standard.

The outer diameter may be in the range of 2 to 55 cm, the walls may have a thickness of 0.25 to 7.5 cm.

Thus, they are divided into three types, relative to the ratio of these values:

- Thin - Diameter / wall thickness = 12.5-40.

- Thick - 6-12.

- Particularly thick - less than 6.

There is also a manual that separates the products by quality (this is GOST 8732-78).

There can be five groups:

- And - mechanical rationing. Made from steel St4sp, St5sp and the like.

- B - chemical rationing. Apply steel calm species.

- B - chemical and mechanical rationing (steel grades are the same).

- G - chemical rationing, as well as special heat treatment, which greatly improves the quality of the finished product.

- D - without rationing.

findings

Well, that was the turn to finish our story, but we made sure that you got a complete set of knowledge. In the presented video in this article you will find additional information on this topic. His viewing will allow to understand all the intricacies.