How and how to bend a pipe: we study features and

Often, newcomers and ordinary citizens who are engaged in laying plumbing, heating or repairing other engineering systems do not know how to bend a pipe without a pipe bender. And situations in which you may need to bend materials of different diameters, shapes and materials occur quite often.

Further in article the instruction will be considered are flexible pipes from various materials.

Instruments

Of course, you can bend using various objects and tools, but if you need to bend a given radius, then use tools such as:

- Pipe benders;

- Machine Volnova.

Main types of pipe benders

Tools such as a pipe bender exist in a huge range of designs. Such diversity has led to the need for classification (see also the article How to bend a pipe at home - in several effective ways).

According to the method of bending, pipe benders are distinguished the following types:

| Crossbow | Completed with forms that are designed to work with products of different diameters |

| Spring | Such tools answer the question of how to bend a plastic pipe. |

| Segmental | Bending is obtained due to the segments around which the pipes are drawn. |

| Dornovye | Designed for pipes with a small wall thickness with a small diameter |

Depending on the type of drive, there are benders of the following types:

- Manual - used mainly for the deformation of pipes of small diameters of non-ferrous metals, polymers or stainless steel;

- Hydraulic - allow you to bend materials with a diameter of more than 3 inches in diameter;

- Electromechanical - allow the deformation of products of different diameters with high angle accuracy.

Council For bending with your own hands it is better to use hand tools, since bending a pipe made of polypropylene, metal, plastic, copper, etc. with their help, anyone can.

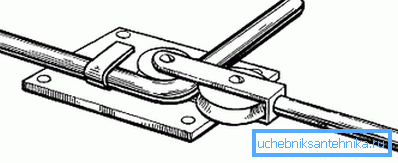

Volnova machine

Equipment of this kind is a simple and easy-to-use mechanism for deforming materials to a cold state.

This machine consists of the following parts:

- Lever;

- Movable roller;

- Staple;

- Plate;

- Hose clamp;

- Clip template.

Note! This type of device is easy to make and at home to an experienced master, besides its price will be minimal.

Features of the bending process

The bending process may be required when constructing a huge number of systems and pipelines. But this process for products made from various materials has its own individual features, which need to be known before beginning the folding procedure.

Fold polypropylene materials

In the process of repairing you can visit the question of how to bend a polypropylene pipe, and can this be done?

Note! Manufacturers of such products, of course, do not recommend this, but in reality polypropylene can be bent.

It is possible to make bending with the help of a building dryer as follows:

- Using a hair dryer, it is necessary to heat the polypropylene to a temperature not exceeding 150 degrees:

- After warming up, you can start the deformation at the desired angle.

Council Wear gloves to prevent burns.

Of course, you can bend in a cold state, but in this case, the deformation radius should not be less than the size of the eight diameters of the pipe itself.

Copper pipes

Copper - the material is quite soft, so the problem that has arisen, how to bend a copper pipe, will not create any special difficulties. However, the process of bending this type of material is dangerous damage.

In order to avoid this you should:

- use dry sand as a filler;

- heat the place of the alleged fold;

- bending should be done carefully, without sudden movements.

Steel pipe bending

Next we look at how to bend a metal pipe.

To do this, you will need the following materials and tools:

- Gas-burner;

- Dry sand;

- Vice;

- Pegs made of wood;

- A pair of supports;

- Kiyanka of rubber.

Almost any thickness and diameter of steel products is bent in the same way, which consists in performing the following actions:

- By means of a vice situation is fixed;

- The bend point is heated with a gas burner;

Council An indicator of the readiness of the material becomes bright red metal.

- The heated pipe starts to bend.

It should be noted that this method is completely unsuitable for galvanized materials.

There are cases when the installation is carried out using products of rectangular cross-section, and then you need to figure out how to bend a square pipe with a small section.

You can do this as follows:

- The pipe is filled with sand, which will act as a deforming frame;

- Both ends are blocked with stakes;

- We begin the curvature to the desired shape using a rubber mallet.

Council If the work is carried out in winter, then the product can be filled with water, after freezing of which the deformation should be started.

We bend metal products

This type of pipeline is often used as the basis for the creation of systems "warm floor".

In this case, the bend of the desired diameter can be achieved by applying one of the following methods:

- The first is the simplest:

- Clamp in a vice;

- We begin the deformation, avoiding bending and carefully monitoring the state of the product;

Council Fold is the rate: for every 2 cm not more than 15 degrees.

- The second - with the help of wire:

- We fill the cavity of the product with pieces of wire of sufficient rigidity;

- We make a bend at the required angle;

- Wire is removed;

- The third - using sand:

- Fill with sand;

- The ends of the product are closed with plugs;

- We fix in a vice;

- Heat the place;

- Produce deformation;

- Remove the plugs and sand.

Finally

The presented instructions will allow you to answer the question of how to bend a HDPE pipe, steel, polypropylene, metal-plastic, etc. Having become acquainted with such methods, it will not be difficult for you to build even the most complicated pipeline yourself (see also How to bend metal-plastic pipes: technology flexible at home).

And the video in this article will reveal even more secrets of the process of deformation of pipes of various types and sizes.