How and what is the connection of metal pipes

There are several ways to connect copper pipes when installing pipe systems. In the construction markets there are many different fittings, fasteners, solders for such material, allowing to perform both detachable and one-piece connections that do not require maintenance. This article will look at all of them, including the connection of metal pipes with threads.

Copper Pipeline Connection Methods

Installation of the system consists of the following steps:

- marking of segments - it is important to make the right measurements with the necessary tolerances in a big way;

- cutting products - made strictly at right angles with a special tool. It is better to make him more turns, so that later not apply extra effort;

- butt trimming - removal of cutting burrs and oxide film;

- pair of segments.

The connection of copper pipes can occur in the following ways:

- capillary soldering;

- high temperature soldering;

- through fittings.

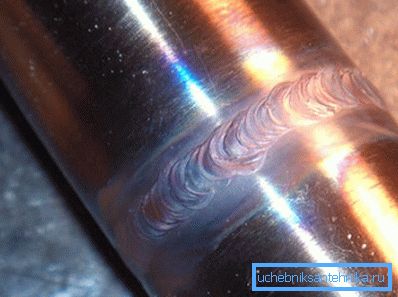

Soldering

Consider how to connect the copper pipes in this way, and below the proposed process instructions will help to understand it in more detail:

- Apply flux to the cleaned surface.

- Connect the parts and apply solder to the joint.

- Heat the joint evenly with a torch or blowtorch until the flux changes in color and the solder melts.

- Remove the burner flame and allow the molten solder to close the gap between the parts and freeze.

Tip: Experts recommend applying a solder bar in length equal to the diameter of the product. You can cut rods of the desired length before soldering. If one of the connection elements is a solder-coated fitting already at the factory, it is not necessary to add it when soldering.

- Do not apply mechanical force after filling the joint, giving it time to cool.

- Remove residual solder and flux from the compound with its wet rag after it is completely cooled.

- Rinse the system with hot water, otherwise the flux will catalyze the development of corrosion. So its presence on the internal surfaces is undesirable.

Fitting

Connecting elements of the system without soldering is possible with the help of fittings, which by their purpose are combined into two groups:

- straight lines - to connect parts of the same diameter;

- transitional - to connect parts of different diameters.

Fittings are made for the entire range of diameters of products. Their price may vary depending on the destination.

Depending on the configuration and functions performed, the following types of fittings are distinguished:

| Clutch |

|

| Square | Designed to change the direction of the system by 30 ?, 45? or 90 ?. |

| Tee | Used for articulation of three segments, located relative to each other at an angle of 45? or 90 ?. |

| Cross | Used to dock together four pipe lengths. |

| Adapter | Other names are sgon or nipple. Serves for interfacing products from different materials and diameters using various methods. |

| Cap | Cap for sealing the pipe end. |

| Fitting | Designed for mating with a flexible hose. |

Here are some ways to work with fittings:

- by soldering, when tin is deposited at the junction of the fitting. A pipe that has been pretreated with flux is inserted into it, then the assembly is heated until the solder melts and fills the gap;

- with the help of self-made threads, when there are corresponding internal and external threads at the ends of the parts to be joined;

- blooming (compression) mating elements of different diameters. The pipe is fastened to the fitting with the help of an annular seal and an upper split or non-detachable ring. Conventional tools are suitable for crimping;

- a press fitting consisting of a body and a sleeve. It is mounted with the help of special press tongs;

- self-locking fitting, the principle of which is based on two rings, one of which is provided with teeth. When it is pressed with a special key, the teeth are pressed into the other ring, ensuring a reliable articulation. It is removed as easily as worn.

Methods of connecting parts of the iron pipe

The tightness of the mates is provided by a rubber gasket installed in the socket.

For connecting cast iron pipes, similar copper cast iron fittings are used:

- couplings;

- knees;

- elbows;

- tees;

- crosses;

- connecting flanges;

- stubs

There are such types of couplings:

| Connecting | The cylinder with the cut female thread, is used for installation of two pipe pieces with the same section. |

| Transient | It has the appearance of a stepped cylinder, equipped with threaded ends - used for joining pipes with different diameters. |

| Knob | A cylindrical part with threads on the inner and outer surfaces, serves as a connecting element in heating systems. |

Tip: be aware that there are also couplings with flanges or sockets at the ends, which allows for the installation of a piping system from parts made from different materials.

The casting of cast iron pipes in the bends of the pipeline is carried out by using bends with different angles of inclination from 10 ° to 90 ?.

They are available in two versions:

- at the ends of the internal thread;

- From one end, external thread, and from the other - internal.

We connect pipes on branches

If it is necessary to join three pipe lengths, two types of tees with internal thread are used: three ends with the same cross section or two ends with the same cross section, and the third - of a smaller diameter.

- The ends of large-diameter tees are equipped with flanges and sockets in various combinations.

- The docking of the four segments is carried out with cross-pieces with sockets or flanges at the ends.

- Cast iron plug is in the form of a cylinder, one end of which is sealed. There are also caps in the form of hexagons, flanged and with ribs for easy installation.

- Fixing flanges for cast iron pipes are made of ductile iron with a protective anti-corrosion epoxy coating.

- Tightness is ensured by an elastic polymer gasket. Mounted by squeezing compression ring.

The installation of cast iron pipes in the case when the secondary pipe is retracted from the main pipeline is performed using a saddle. Then clamps, valves or a secondary pipeline are attached to it with clamps.

Conclusion

The article described in detail the possible ways of connecting metal pipes, in particular copper and cast iron, to each other. Each method has its own characteristics, therefore it is used in certain cases (see also the article Electrowelded Pipe: technical parameters and scope).

The video in this article will help you find additional information on this topic.