How is pipe strength and other important parameters

When installing household pipelines, the calculation is not carried out, since standard pipes are used for these purposes, the strength of which is quite enough to withstand the pressure of water, gas, etc. But building industrial pipelines without a specific calculation is dangerous in most cases, as this can lead to rapid failure of the system and other unpleasant consequences.

In this article, we will look at the basics of how to calculate the strength of a pipe, as well as some other parameters that you need to know before building a structure.

Strength calculation

I must say that the calculation of the strength of the pipe is needed not only to ensure that the line is reliable. This will also avoid overspending, because excessive strength will lead to higher construction costs. Therefore, the design is not less important stage of construction of the pipeline than its installation.

So, this calculation involves the definition of several basic parameters:

- Internal diameter of the pipe depending on the flow rate of the transported liquid;

- Internal diameter depending on hydraulic resistance;

- Wall thickness.

Each parameter is determined by certain formulas, which we will examine below.

Calculation of the internal diameter

Determine the optimal internal diameter of the pipe at a given flow rate of fluid in the pipeline and its flow can be done by the hands by the formula - D = 4Q3600v? Y m, where:

- Q - fluid flow, measured in mg / h.

- v - the rate of flow of fluid in the pipeline, measured in m / s.

- y is the specific gravity of the fluid with the given parameters, measured in kg / m3. This value is taken in reference books.

The speed of movement of various liquids and gases is determined by calculations, and also confirmed by practical experiments. Therefore, in the calculations, you can use the following data:

| For water and various low-viscosity liquids (such as acetone, alcohol, weak solutions of alkalis and acids, gasoline, etc.) | 15 - 30 m / s |

| For high pressure gases and superheated steam | 30-60 m / s |

| For saturated steam and compressed air | 20 - 40 m / s |

From the above formula it follows that the diameter of the cross section of the pipeline depends on the rate of flow of fluid. The higher it is, the smaller the flow area should be, respectively, the construction costs of the structure will also be lower.

Hydraulic resistance

When a liquid or gas moves through a pipeline, resistance necessarily arises as a result of friction of the product being transported against the pipe walls and various obstacles in the system. This resistance is called hydraulic. The higher the flow rate and density of the fluid, the greater the hydraulic resistance.

The diameter of the pipeline can be determined by a given pressure loss.

The instructions for performing this calculation are as follows - D =? L? P • y • v2g kgf / cm2, where:

- ?p = P1-P2 is the specified or allowable pressure loss between the initial and the final point of the pipeline, measured in kgf / cm2.

- L is the length of the trunk.

- ? - the coefficient of hydraulic resistance may be 0.02—0.04.

- g - acceleration of gravity, which is equal to 9.81 m / s.

Of course, this calculation allows us to determine the pressure loss in a straight pipe. As for the determination of this indicator of reinforcement and fittings, it is found by pressure loss in a straight pipe section of the corresponding diameter and with equivalent length.

Equivalent length is called a straight pipe section, the hydraulic resistance of which is equal to the resistance of the shaped part under equal other conditions.

Wall thickness

The main parameter of the pipe, which affects the strength, is the wall thickness.

This indicator depends on several factors:

- Internal and external pressure exerted on the pipe;

- The diameter of the pipeline;

- The material from which the pipe is made and its corrosion resistance.

Most pipelines are affected only by internal pressure. Vacuum pipelines, as well as jacketed systems intended for steam heating of easily hardening or crystallizing products, are subject to external pressure.

The wall thickness of steel pipes, which are affected by internal overpressure, is determined by calculation of the strength and the added thickness, which is allocated to wear from corrosion.

To do this, use the following formula - S = Sp-C,

- Sp is the calculated thickness, measured in mm.

- C - increase in corrosion. As a rule, it is 2-5 mm (for medium aggressive media).

The calculated wall thickness can be obtained by the following formula - Sp = pDн230? Additional? + P mm, where:

- p — excess internal pressure in the pipe, kgf / cm2.

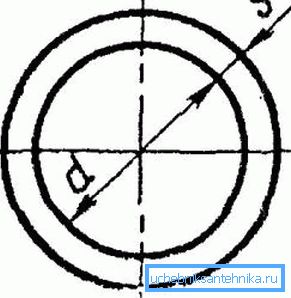

- Dн — outer diameter of the pipeline.

- ?Dop - permissible stress at break, sgc / mm2. This indicator can be determined by reference books, depending on the temperature of the transported fluid and steel grade.

- ? - the coefficient of strength of the weld. If the pipe is seamless, then the coefficient? = 1. For welded pipes, this figure can be 0.6–0.8, depending on the type of weld and type of welding.

Note! When installing the pipeline, as well as in case of its repair, it is impossible to install separate random parts made of untested or unknown material, as this may lead to an accident in the system.

It must be said that in the calculation of pipelines, attention is paid not only to the thickness of the pipes, but also to the material itself. For example, if the temperature at which the system will be operated is less than 450 degrees Celsius, then use pipes made of steel grade 20.

If the temperature of the transported product in the system is high, then choose steel 12H1MF. This allows the use of pipelines with thinner walls. Accordingly, the cost of construction depends on the thickness of the walls.

Pipeline stability

When calculating highways in addition to the strength of the pipeline, an important parameter is its stability in the longitudinal direction.

This calculation is performed from the condition - S? MNcr, where

- S is the longitudinal equivalent axial force in the cross section of the system.

- m is the coefficient of the system operating conditions. This value is in the reference literature.

- Ncr - critical longitudinal force at which the pipeline loses longitudinal stability. This value must be determined in accordance with the existing rules of structural mechanics, taking into account the initial curvature of the system, the presence of ballast that fixes the pipeline, and the characteristics of the soil. In wet areas it is also necessary to take into account the hydrostatic effect of water.

Note! Longitudinal stability should be checked for curved sections in the plane of the bend of the trunk. On straight sections, the longitudinal stability of underground sections should be checked in a vertical plane, the radius of the initial curvature being assumed to be 5000 m.

The longitudinal equivalent axial force should be determined depending on the design loads and impacts, taking into account the transverse and longitudinal movements of the main line.

The calculation is performed according to the following formula -

S = 100 [(0,5-?)? Kc +? E? T] F

- ? - coefficient of linear expansion of the pipe material;

- E - variable parameter of elasticity;

- ?t is the temperature design difference;

- ?kc — annular stresses from the internal design pressure;

- F is the cross-sectional area of the pipeline.

Note! When determining the stability of above-ground highways, it is necessary to calculate the anchor supports, arched systems, anchor hanging supports and other structural elements for the possibility of shear and tilting.

Strength classes of steel pipes

So that after performing all the necessary calculations of the strength of the pipeline, it was easier to select suitable pipes, the strength classes of the pipes were introduced. In this case, the strength of the products is estimated by the tensile strength of the metal.

The strength group of pipes is denoted by the letter “K” and the standard value in kgf / mm2 from 34 to 65. For example, gas pipelines in the middle belt areas, taking into account the average ambient temperature of about 0 degrees Celsius and a system operating pressure of 5.4 MPa , are made of pipes of strength class K52.

In the conditions of the Far North, where the average temperature is -20 degrees Celsius and the operating pressure in the system is planned to be 7.4 MPa, gas pipelines are made of pipes of strength class K55-K60.

Calculation of the mass of the pipe

In most cases, when calculating the system, it may be necessary to value the mass of the pipes, for example, to correlate it with the bearing capacity of the supports or simply to predict transportation costs.

However, for this there is no need to calculate by a mathematical method how much a specific section of a pipe weighs, since the reference information contains the exact weight of a running meter of various types of pipes.

It is enough to know the following information:

- Pipe material;

- External diameter;

- Wall thickness, etc.

After the weight of one running meter will be known, this value should be multiplied by the number of running meters.

Surface area

When installing different highways, they may need to be insulated, waterproofed, painted, etc. To do this, you need to determine the area of the pipeline, which will allow you to calculate the amount of material. To perform this calculation, it is necessary to multiply the circumference of the outer section by the length of the pipe.

The formula for determining the circle is as follows - L =? D. The length of the pipe segment is denoted as H.

In this case, the area of the outer circumference of the pipe will look as follows - St =? DH m2, where:

- St is the surface area of the pipe, which is measured in square meters.

- ? - The number of "pi", which is always equal to 3.14;

- D is the outer diameter;

- H - as mentioned above, indicates the length of the pipe in meters.

For example, there is a pipe 5 meters long and 30 cm in diameter. Its surface area is St =? DH = 3.14 * 0.3 * 5 = 4.71 square meters.

Based on the above formulas, it is also possible to calculate the volume of the pipeline and the area of its internal walls. To do this, it is only necessary to change in the calculations the value of the external diameter by the value of the internal one. All these parameters may be required when installing a domestic pipeline.

Conclusion

We looked at the basics of how pipelines are calculated for strength and stability. Of course, when installing industrial highways, a much more complicated design is carried out, which involves a number of other actions, so this work is done exclusively by professionals. However, when building a household system, all the necessary values can be learned independently.

From the video in this article, you can get more information on this topic.