How is the bending of profile pipes

The frame, made with the help of shaped pipes, is a fairly frequent building structure. It is used, including for greenhouses, greenhouses, awnings and canopies with a spherical shape.

In this case, there are two ways to make the necessary shape - use a welding machine or pipe bender.

Below we consider the use of special equipment for such purposes, as well as alternatives. So you can decide whether to spend money on its acquisition or it will be possible to limit it to an alternative method.

Advice: make sure that when bending the profile pipes there are no cracks, kinks and flattening.

What industry offers us

Below we consider the main types of benders, which are most often used:

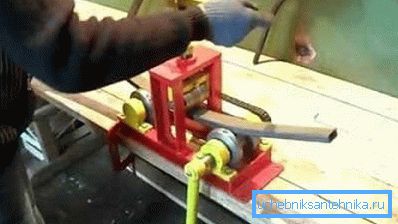

| Compact manual |

|

| Electric |

The disadvantage of the equipment is its high cost and high weight, which limits its availability for the average buyer. |

Alternative methods

Use a welding machine and angle grinders

If you do not have a pipe bender nearby or the cost of services does not suit you, it is possible to bend the profile pipe with your own hands at the right angle at home.

To do this, you must prepare a grinder or "grinder" and a welding machine, the instructions below will tell you how to do it:

- Draw a diagram on which calculate the radius of rounding.

- Make in the place where it is supposed to bend the pipe, angle grinder with a disk on metal several transverse cuts.

- Clamp the pipe in a vice and start to bend it in the direction you need, applying a small force.

- Weld the cuts with a welding machine when the bend angle will suit you. Do not forget about the observance of the rules of TB.

Tip: in the last step, grind the welds.

Sand and metal disc

This method does not require any special tools, so it can be considered one of the most simple, albeit time-consuming.

If you do not know where to bend the profile tube, use it:

- Prepare the sand, which should be enough to fill the entire pipe. Be sure to dry and sift it.

- Cover one end of the pipe with a wooden chop.

- Pour the sifted sand into it and also plug it on the other side.

- Take a metal disc of a suitable diameter.

- Securely secure one end of the profiled tube between the pins, pull after the other, tapping the disc on it.

Tip: to facilitate the process of bending the profile along a small radius, it is better to warm the deformation site with a gas burner. The integrity of the metal walls during the process will provide tight sand.

- Remove the clogged chop after bending the profile, they need to be knocked out or burned out.

- Remove the sand from the pipe completely.

The method is quite complicated, so it is usually used for one-time pipes. In winter, the sand can be replaced with water, which should freeze inside the profile; do not forget to securely close the ends with traffic jams.

As soon as the liquid in the pipe freezes, you can begin to bend it according to the prepared pattern.

Apply a square spring

Professionals know another way that will not allow the walls of a metal shaped tube to deform - using a spring with a cross section of the same shape, but smaller. For its manufacture used steel wire, the diameter of which depends on the thickness of the walls.

The main thing - it should effortlessly go inside the product. Then the planned place of bending should be heated by a gas torch or a blowtorch, since then the walls will be more easily bent.

Use special protective gloves when holding the product with pliers. To obtain the desired radius, use a blank or metal pins, which should be reliably mounted around the circumference.

Conclusion

The article gave an idea of how you can bend a profile pipe to the desired radius. To do this, there is a special equipment that facilitates the process, or you can use "folk" methods, if the machine is too expensive, the cost of bending services is not suitable for you or you cannot reach them (see also the article Butt-welding: technology and equipment).

The video in this article will help you find additional information on this topic.