How is the welding of pipes made of steel for the heating

Today, welding of heating pipes is still a widely used technology for joining system elements. The fact is that modern plastic pipes are not everywhere acceptable to use. Yes, and often it happens that you need to create a highway that will heat absolutely the entire inner perimeter of the house, and not just the space under the windows.

To solve this problem, plastic is not suitable because it does not heat itself, like metal. And accordingly, only radiators become heating points.

The nuance is that the welding of water pipes of this type involves the following:

- Availability of special equipment.

- Must be the experience of welding metal. And the understanding of the basic principles of welding will not be superfluous.

That is, it turns out that doing this work with your own hands is difficult enough. But still, if desired, it is quite real.

In this article we will try to reveal the basic rules for installing such a system using a welding machine. A review of the technology and welding instruction will be useful to you at least so that you can objectively evaluate whether you can perform such work or not.

Let's start with the most important moment.

The principle of technology and what is needed for its implementation

As a visual example, we will consider the simplest option - docking using electric welding.

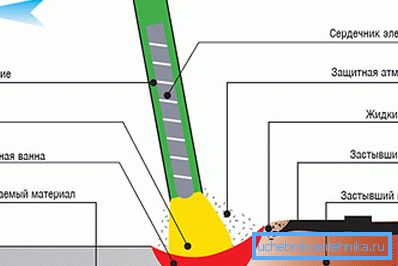

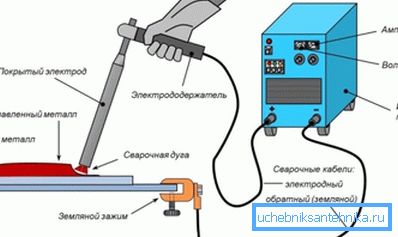

- In fact, it is a very reliable way to connect various metal products.. The physics of the process is that special equipment is taken for welding pipes to which electrodes are connected (these are metal rods with special spraying).

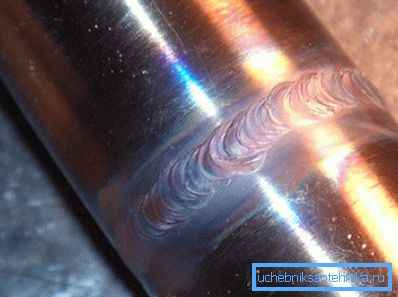

- These electrodes under the influence of electric current melt, fill the space between the seams of the pipes, and then solidify, as if turning into solid metal again..

Please note that it is very important to use high-quality electrodes in the work - otherwise you can get a leaky and fragile connection. Therefore, do not save - it is better to purchase a product, the price of which is high, than to do all the work in vain, agree.

Let's look at the comparative table, what kind of electrodes in general, depending on the coating.

| Type of spraying: | Features and scope of application: |

| 1. Basic, basic coverage. | Products have a good level of viscosity and the probability of cracking of the seam is very low here. Such electrodes are used for private simple tasks. |

| 2. Rutile cellulose. | A great option for creating complex seams, including vertical. |

| 3. Rutile and rutile acid. | The material is distinguished by the ease of “ignition” and the fact that the slag (excess build-up on the seams) is easily removed after work. Such electrodes are conveniently used for “tacking” metal and creating angular connections. |

| 4. Pulp. | If welding of pipes of large diameter is performed, then this is the best option. Using cellulose rods, you can make high-quality ring and vertical seams. |

It turns out that standard rutile and cellulose electrodes are suitable in principle for assembling a heating system in a private house.

As for the diameter of the rods, there is a very simple "formula" of calculation. Electrodes with a diameter of 3 mm are optimal for welding products with a metal thickness of 2-5 mm. The greater thickness of steel in heating systems in private homes, as a rule, does not apply.

Well, a few words about the equipment. If you do not go into details, the welding machine is a transformer, through which current is transferred to the end of the electrode. The cost of such equipment, in principle, is not very high, but is it worth buying it for a one-time job? In most cases, it is easier, safer and cheaper to entrust the heating assembly to a professional.

With the principle of technology figured out, now let's try to implement it step by step.

Heating pipe welding

Before you start it is worth noting that there is a GOST for pipe welding, with the help of which you can decide what kind of weld to create with one or another edge shape.

Pay attention also to the fact that the pipes come in different shapes - not only round, but also square and even rectangular. So the welding of square pipes according to GOST may differ slightly from the rules of joining round products. Consider this point and carefully look at exactly what documentation you are reading.

Well, now back to work directly.

Preparation of the base and equipment

The procedure at this stage should be something like this:

- We take the pipes and make them so that their edges (that is, as if circular seams) are cut off at the most even angle with respect to each other.

- We clean the edges of the seams with sandpaper with a fine fraction.

- We connect the transformer to the network and prepare the welding machine for operation. If the device is properly configured, the sound from the contact of the electrode and the metal will be as if dry, crackling.

In principle, this preparatory work is completed, and you can proceed to the next stage.

Tack

Tacking is called a pre-point connection of elements.

- It is necessary because to create a strong and beautiful seam right away is unreal.

- It is easier to first weld the roughing points of the pipe joints so that the products are fixed relative to each other, and only then to strengthen the entire annular seam.

Note! Remember that very often when working with heating systems, pipes are not welded. That is, to put it simply, turning the trunk around its axis in most cases will not work. And this means that the welder will need a maximum of skill, since it will be necessary for each point to select the optimum angle of the electrode.

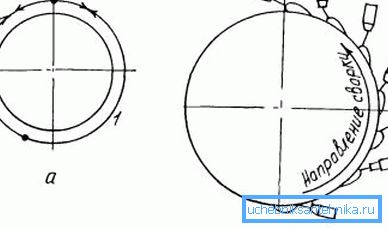

- Pre-docking should start at the bottom of the “ring”, then you need to do side tacks, and then fix the top. If you immediately fix the top and bottom, then there is the likelihood of fixing elements at the wrong angle.

- If we talk about the number of points, then you can use a very simple formula - if the diameter of the products does not exceed 30 centimeters, then 4 tacks are enough.

In general, it is necessary to strive to create junction points when the electrode is perpendicular in relation to the main line. However, this, of course, is possible only in the case when the elements can be rotated around the axis.

If the roughing is realized, then you can begin the finish welding.

Creating the main seam and slag stripping

So, the final welding of water pipes is performed in the following sequence:

- The pipe is visually divided into 4 sectors and first of all they weld its upper “hemisphere”.

- Next, the lower sectors are processed.

- On the upper and lower "hemisphere" is applied another layer of the seam. This is necessary not only for the strength of the connection, but also to obtain the maximum tightness of the pipe connection.

As for the situation, when it is necessary to make the joining of highways of different diameters, the simplest option is to embed one product inside another and then weld them to each other. If the difference in diameter is very large, then, of course, will have to use adapters. By the way, there may be several adapters and they can be interconnected by the same principle - that is, as if inserted inside each other.

When welding work is completed, slag can be stripped. This is, in fact, ordinary grinding of excess growths at the junction. However, it is important not just to clear the ridges, but to check the quality as a whole. That is, you need to try to identify cracks, pores and burn-throughs.

If outwardly everything seems normal, then apply the usual soap solution to the seams and run air under pressure into the system. If they have microcracks, then bubbles will appear in such places.

Conclusion

We have dealt with in some detail what is the technology of welding metal, how to perform welding of pipes of different diameters and “at an angle” when installing a heating system in a private house.

We hope that the review was useful to you, and you will be able to objectively figure out whether it is worth taking up such a thing on your own. If you want to know even more - then check out the thematic video in this article.