How is welding propylene pipes

Plumbing in your house or apartment usually requires soldering of propylene pipes with your own hands, unless, of course, plumbing or heating is done with plastic or steel pipes. There are several types of welding machines for PP, but you can use any of them, regardless of its power, shape and cost.

You can easily learn how to do it yourself, as we will tell you below, and also show visual information on the video in this article.

What is needed for soldering PPR

Note. English abbreviation PPR and Russian - PP designate polypropylene pipes of any size. In the article we will use the following notation.

Welding tool

- A tool such as Eral ER-01 (LUX) is used for welding PPR and fittings with a total diameter of 16 mm to 75 mm - for larger pipes, larger nozzles are needed, therefore a more powerful unit is needed. In this case, we have an xiphodial type electric soldering iron with two 750 W power units each, so that we get a total of 1500 W - there is the possibility of autonomous operation of each of the heating elements. The thermostat allows you to set the temperature to 300? C, which is enough for wiring plumbing and heating.

- The welding machine CANDAN SM-04 allows the use of nozzles from 16 mm to 125 mm in diameter, which covers the full range of polypropylene pipes used for their soldering with fittings. Here, too, two autonomous fuel heaters are installed, but already 1000W each, therefore, at the output we have 2000W - the unit copes well with tasks at an industrial level - the temperature range is from 50? C to 350? C. Only three paired nozzles — 50 mm, 63 mm, and 75 mm — are supplied with the device; the rest should be bought if necessary.

- The cylindrical apparatus STURM TW-7218 differs from similar xiphoid instruments in its shape and attachments - in this case, soldering of polypropylene pipes is carried out by unpaired attachments, but the principle does not change. Power STURM TW-7218 is 1880W, and the maximum position of the thermostat knob - 300? C. The kit includes three nozzles 20 mm, 25 mm and 32 mm, a hex wrench and a screwdriver.

- Despite the fact that a soldering iron for propylene pipes is usually completed with only three or five nozzles, you can always buy them, given the need at one time or another. Such devices are made of aluminum alloy, which allows them to warm up very quickly (aluminum in thermal conductivity takes 3rd place after gold and silver). But some modifications have a Teflon coating - this almost completely eliminates sticking of PP to metal, therefore, facilitates the work process.

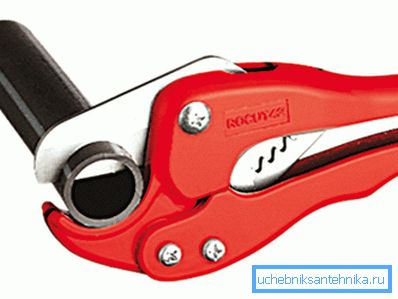

- For cutting polypropylene and metal-plastic pipes special scissors are used.. The quality of such a tool, as a rule, depends on the fixation of the blades with respect to each other, so they should not have a backlash and then the cut will be smooth. Often this tool comes with the device, but high-quality scissors are best purchased separately.

Welding work

Before you start welding, you need to figure out which pipe is in front of you - RN10, RN16, RN20 or RN25 - the method of soldering will depend on it. The fact is that PPR RN10 and RN16 have a solid wall, but RN20 and RN25 are reinforced with aluminum foil or fiberglass. Only here at RN20 the reinforcing foil is located in the middle of the wall, and at RN25 - closer to the base.

The aluminum foil close to the top interferes with the soldering, because when it enters the nozzle, the aluminum layer is exposed and it turns out that it will have to stick together with the fitting, but this lowers the quality of adhesion and, therefore, the connection itself.

Therefore, for RN25, a shiver is used, clearing the end (top layer of PP and foil) as in the photo above. But such pipes are designed for a constant temperature of 95? C and a jump up to 150? C, therefore, they are used extremely rarely (mainly - for centralized heating), besides, they have a rather high price.

Polypropylene fittings are used for docking, which can be:

- straight (coupling);

- angular (32 ?, 45? and 90?);

- reduction (transition from one diameter to another);

- threaded (to go to the metal);

- tees and by-tubes.

In addition, polypropylene cranes are produced, in which the operational resource is much higher than metal, therefore, it is better to use them on the main line. Fixing such a pipeline is carried out by plastic or metal brackets and clips.

Note. For welding, all work items (PPR and fitting) must be dry and free from grease. Only identical sections can be joined.

The table of the depth of immersion of the pipe in the fitting and the time of their heating / cooling:

| Pipe section (mm) | Welding depth (mm) | Heating time (s) | Cooling time (s) |

| 20 | From 14 to 17 | 5-6 | 2-3 |

| 25 | 15 to 19 | 6-7 | 3-4 |

| 32 | 16 to 22 | 8-9 | 4-5 |

| 40 | From 18 to 24 | 12-13 | 5-6 |

| 50 | From 20 to 27 | 18-19 | 6-7 |

| 63 | 24 to 30 | 24-25 | 7-8 |

| 75 | 26 to 32 | 30-31 | 8-9 |

| 90 | 29 to 35 | 40-41 | 9-10 |

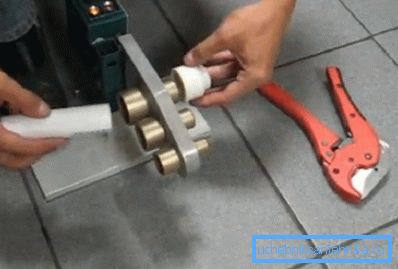

Soldering is carried out in several stages, as can be seen in the upper photograph of the fragments — the fitting and the end of the pipe are first heated, then they are simultaneously freed from the nozzle and at the third stage are joined to each other.

And here it is important for you to pay attention to the table located above - there you will see at what distance you need to drive the pipes to the fitting, how much to heat them in the nozzle of the soldering iron and how much to cool (hold) after docking. If you do everything correctly, then as a result you should get a ration, as shown in the section (fragment of the photo №4).

These parameters are extremely important, because if the pipe gets too deep into the fitting, its end will rest on the partition and flatten out, reducing its permeability, or it will generally cause a blockage. In order not to be mistaken, before heating on the PP, mark with a pencil or marker at the desired distance and be guided by it.

Conclusion

It should be noted that the installation of a polypropylene pipeline is much more convenient to produce in blocks, rather than one element at a time — you weld a specific fragment separately from the route, and then you join it to a common contour. If, when working in the first place, you have the instruction that you received above, then you should go through everything without any force majeure and the connections will turn out to be of high quality (see also the article Connecting pipes: pipelines and steel structures).

Successes!