How much does the pipe weigh 80 to 80 to 4 and what does

As is known, the cylindrical shape is more suitable for transporting liquids or gases. Profile products are used in places where resistance to external loads is appreciated. Among the core products, the square is considered to be the most convenient and durable section, therefore 70% of the 80x80x4 pipe is made for the construction industry and only 30% is distributed in other areas.

In the most common marking of this profile, its dimensions are initially indicated. The numerical values of 80 by 80 indicate the dimensions of the sides of the square along the outer contour. At the very least in the row number 4 indicates the wall thickness. According to all known standards of GOST, the default characteristics are calculated in millimeters.

What is this profile good for?

- As mentioned earlier, a square profile with transverse external loads shows almost the highest characteristics.. Laboratory tests, as well as any installation instructions, suggest that in terms of reliability, only an I-beam can be compared to a square. But beams with a complex configuration, unlike a square, can not be installed everywhere.

- The realities of modern production are such that, according to the requirements, all the material must be covered with a protective anti-corrosion coating; as a result, frames of square beams can last at least 50 years.. Stainless steel and alloy metals do not need such treatment, as they are not susceptible to corrosion.

- Profiles with flat, perpendicular walls are much easier to attach to almost any surface.. In construction, in the construction of frames it is very important, the convenience of fixing the outer and inner facing covering plays an important role.

- The weight of a square pipe is 80x80x4 mm, it allows you to mount it on almost any basis, without fear of structural overload.

- The light weight of the pipe is 80 by 80 by 4, which makes it possible to additionally place in the construction any hidden electrical wiring. The size of the internal square cavity of 72 mm, allows even to hold the hidden pipework in it. At the same time the metal casing of the pipe provides communications reliable protection.

- The square shape is probably the most convenient in terms of packaging and transportation.. Compared to other profiles of similar size, stock of this product is in the lowest place in stock, despite the fact that the weight of the pipe is 80x80x4, may be the same as that of the round counterparts.

How much does the pipe weigh

To perform accurate calculations of metal structures it is often important to take into account the weight of 1 meter pipe 80x80x4. Although the overwhelming majority of these structures are used in the construction industry, but apart from this, frames for various kinds of mechanisms and machines can be made of them. In professional design in mechanical engineering, it is important not only to take into account the load on the node, but also the mass of each element of the unit.

What design parameters depend on

No one will argue with the fact that the weight of any structure consists of the mass of material from which it is made, in this case it is metal. Let's take a closer look at what makes up the weight of a 80x80x4 square pipe.

First of all it is a form. The square shape is most convenient for mounting most of the nodal connections in any designs. The thickness of the metal in 4 mm provides the necessary strength for building frames of medium size or the design of supporting units of machines and mechanisms.

For everyone, without exception, building frames or units in mechanical engineering, the dimensions of the product itself are important, that is, what are the aspect ratios and wall thickness. In addition, the same parameters are fundamental in the production process.

After all, the thicker the wall will be, the more metal will be required for its manufacture, plus for products of medium and large diameter, production is associated with increased energy costs, hence the price increases.

The weight of the pipe is 80 by 80 by 4, as well as any other specialized product, directly depends on the density of the metal from which it is made. Agree, the density of alloyed steel is significantly different from the density of non-ferrous metals, for example, aluminum or copper. Classically, this is the ratio of the mass of the metal, to the fixed volume that this metal fills, this parameter is measured in kilograms per 1m ?.

Naturally, more dense metals have a high specific weight. It is only at first glance, not knowing the person it may seem that all the iron weighs the same. If we talk about the range of steel from which this profile is made, then the density here ranges from 7500 kg / m? To 7900 kg / m ?. From here and the weight of 1 meter pipe 80x80x4, will differ significantly.

Why do you need this information

Many believe that for the design and construction of relatively small building structures or aggregates, the accounting of mass does not play a big role. But this is far from the case; any machine or frame has mates of bearing parts. Excessive loads can occur at these connecting nodes in case of an error.

The second equally important point is the price of the goods. Pipe weight 80x80x4, directly determines its cost. After all, it is customary in the trade to release such a product not in running meters, but in terms of tonnage.

The reason is simple - it is difficult, and sometimes impossible to measure each product in the package. Plus, in this case, it will be necessary to take into account everything by the piece. It is much easier to calculate the total footage, depending on the mass.

Calculation methods

As mentioned earlier, the price of such a product is tied to the mass. But to find out how many meters of the product will be in one purchased ton, you must first calculate the weight of 1 meter of pipe 80x80x4. Fortunately, all the common methods of calculating core products are more oriented precisely to the square or rectangle.

There are complex formulas for calculating the mass of a product with a specific configuration, but it is simpler to make a sweep of the perimeter of a section of a structure and count it as sheet metal. In this case, for calculating with your own hands, you only need the sheet thickness, its quadrature and the specific weight of the specific alloy.

Important: if you need an approximate weight of a square pipe of 80x80x4, then this method is quite suitable. Although, of course, it will be easier to take the average value for steel, equal to 9.33 kg per 1 running meter.

It is a bit more complicated if you need accurate data, the fact is that a square can be of two different types. With sharp, perpendicular or rounded edges. For a perpendicular configuration, any formula will do, but if the edges are bent, then you will need to take into account the radius of curvature.

You can go the other way and look at the range of material according to GOST for a particular steel grade. In these regulatory documents, the most accurate reference parameters of the product are indicated, including the estimated weight of the pipe is 80 by 80 by 4, more precisely, 1 running meter. But we should not forget that the allowable discrepancy between tabular data and real mass is from 10 to 12%.

But there is a universal way, the accuracy and speed of which is difficult to question. If you say simply, then this option can be called a way to perform calculations for the lazy. At the moment, people most often use the online calculator.

After all, it is really convenient, everyone can make the requested parameters with their own hands and get the result. And this does not require deep professional knowledge.

Important: in addition to the certificate certifying the quality of the goods, a batch or a passport is issued for each item. In this document, along with the steel grade and dimensions, it is necessary to provide information about the weight of 1 meter pipe 80x80x4.

Production methods

A wall thickness of 4 mm allows such structures to be produced with all existing technologies. In this case, it would not be correct to say that some kind of technology is given special priority. The choice will depend on the presence of certain characteristics in the final product.

Hot rolled technology

This technology is considered to be a classic production. If we talk about quality, then any pipes, regardless of the configuration or wall thickness, will have the highest characteristics when fabricated in hot rolling mills. But this technology is distinguished by the largest energy consumption, naturally because of this, the cost price and price increase many times over. (See also the article Hot-rolled pipes: features.)

For the manufacture of products used crimp billet, initially round. Two different preheating technology can be used. The first is considered to be traditional, here the disc is heated with natural gas to 1200? С.

The second, more progressive and environmentally friendly metal is heated here in high-frequency electric current in induction furnaces. It is usually used in the manufacture of high-precision structures of alloyed or expensive non-ferrous metals.

After rough crimping, the blank is subjected to the mandrel procedure. In this case, we are talking about forcing and rolling out the cavity inside. In other words, at this stage a pipe is made from a single piece of metal. After the mandrel, the product enters a special molding press, where the profile of the future structure is pre-formed.

At the finishing rolling line, the pipe is adjusted to clearly defined dimensions. After repeated crimping and molding, the structure is cooled.

Important: the instruction, in this technology prescribes gradual cooling, otherwise the metal will lose its elasticity and become brittle.

Cold rolling

Here, the structure is drawn out and molded from sheet metal, under high pressure. Apart from the stretching process itself, by and large, the treatment resembles the previous version. But the difference lies in the fact that after the final molding, the metal needs a “vacation”. This process consists in heating to a temperature of 700 ° C and gradual cooling.

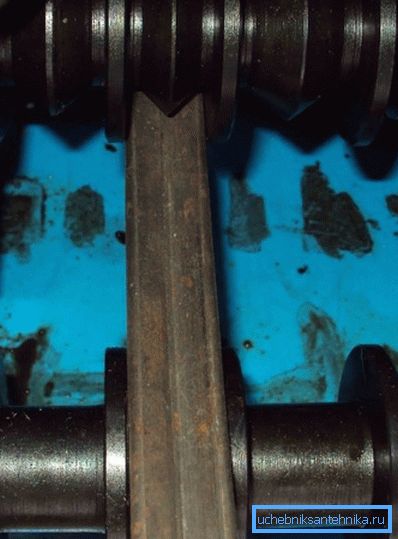

Welded products

Longitudinal welding is the most affordable production option. This line does not require large areas for accommodation and significant energy costs. As a result, the price of such pipes is quite budget, most often they are used in construction. The meaning is simple, the metal sheet is bent and welded by electric welding.

On the video in this article you can get more information on the topic.

Conclusion

This profile is one of the most popular, it is used both in precision engineering and at construction sites. In addition, decent performance and low pipe weight 80x80x4, fully allow the use of such structures in private construction.