How pipe cutting is performed: implementation principle

For pipelines for various purposes, the materials need to be adjusted and nowadays various methods of fragmentation can be used for this, for example, laser cutting of pipes as one of the most accurate types of machining parts. There are other methods, the basis of which can be called flameless cutting, that is, this means that torches such as a gas burner or gasoline cutter are not used, which significantly increases the fit accuracy.

We will talk about such units and how to use them below, as well as provide you with a thematic demonstration of the video in this article.

Pipe fragmentation

Note. The simplest tool for cutting their own hands at home can be called a hacksaw for metal. But such a tool can only cut profiles with a small cross section, moreover, with the help of a canvas it is very difficult to maintain a flat line along the entire perimeter, therefore, we will not consider this method.

Types of equipment

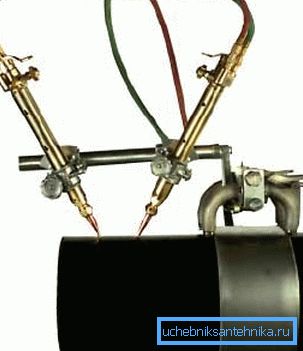

- Such equipment for cutting pipes, like a machine in the upper photograph, can produce turning processing of pipes, columns and various parts of the pipeline, which is extremely necessary in geological exploration, oil, gas and ore dressing industry, in mechanical engineering. This machine is chosen taking into account the following parameters: the cross section of the spindle holes; distance between two centers; maximum section of a part for processing; the presence or absence of a semiautomatic machine for threading; the stability of the bed.

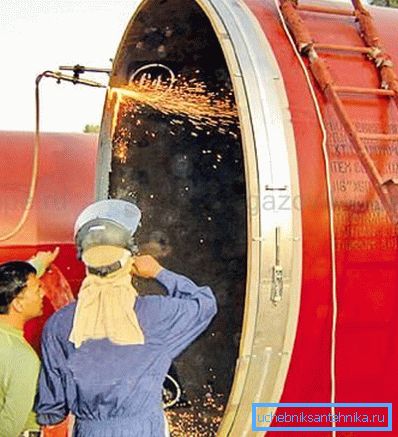

- The tape machine for cutting pipes "MONARCH BAND MACHINE" is used when the pipeline is already in a trench or there is a shortage of free space during processing. It is noteworthy that the stainless tape takes only 153 mm, which is almost negligible for a large cross section. When finishing with such equipment, the diameter is possible from 159 mm to 1529 mm, and in addition, the machine can chamfer even from a strongly deformed end of the pipe.

- Such stations are used for billets of black and stainless steel, and here the cutting of a shaped pipe of small and large diameter of round, square and rectangular cross section, which are fed for sawing by an automated station, is carried out.. In addition, the automatic line is equipped with a unloading station, which can accumulate ready-made fragments.

| Diameter | mm | 10-100 |

| Cross section of square and rectangular profile | mm | 1010; 6585/1510; 10060 |

| Wall thickness | mm | 1-5 |

| Length | mm | 4000-8000 |

| Cut length | mm | 340-8000 |

| Drive (motor) power for one saw head | kw | 3.3 |

| Disc diameter | mm | 270-350 |

Automatic disc cutting line

- Axxair CC121fs has the ability to perpendicular cutting without burrs, the maximum deviation of 0.25 mm, and, thanks to the clamp, you can avoid deformation even when cutting thin-walled pipes. Such mechanisms are quite compact and have low weight, which allows them to be used not only in the workshop, but also on the construction site. The CC series is equipped with a manual wheel of the rotation system, facilitating the cutting process, and in addition, it is completed with orbital welding.

- A pipe cutting tool like FIN&FICEP is designed for fragmentation by size, cutting of various shapes, as well as for chamfering.

| Model, series | PB |

| CNC axis (pieces) | 6 |

| Possible diameter (mm) | 060-01420 |

| Wall thickness: air plasma (mm) | 5-25 |

| Wall thickness: gas (mm) | 5-10 |

| Possible length (mm) | 800-12000 |

| Maximum weight (kg) | 6000 |

| Possible intersection angles | 20? -160? |

| Clamping device | 5 grabs |

| Chamfer at an angle | 30? -150? |

| Electronic clip holder | 1 set |

| Longitudinal movement (Y axis): stroke value max. Positioning speed positioning accuracy | 12,000 mm 10,000 mm / min 0.3 mm |

| Moving back and forth (X axis): stroke value max. Positioning speed positioning accuracy | 600 mm 1500 mm / min 0.2 mm |

| Moving up and down (Z1 axis): stroke value max. Positioning speed positioning accuracy | 560 mm 1500 mm / min 0.2 mm |

| Pipe rotation (axis?): Rotation angle rotation speed positioning accuracy | Not limited to 0-8 rpm 0,2 ° |

| Torch radial stroke (axis? 1): tilt angle tilt speed positioning accuracy | ± 45 ° 0-18 rev / min 0.2 ° |

| Torch inclination for chamfer (axis? 2): inclination angle inclination speed positioning accuracy | ± 60 ° 0-18 rev / min 0.2 ° |

| Color touch screen | 1 set |

| Gas cutting torch | 1 set |

| Pipe support module | 6 items |

Technical Specifications FIN&FICEP

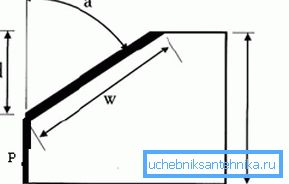

Chamfer

Explanation. In the upper figure, the value: a is the angle of removal; P bold blunting; d - depth of cutting or leg; w - bold width; H is the total thickness.

There are only three ways to chamfer the workpiece - it is X-shaped, Y-shaped and J-shaped methods, which can also be labeled V, K, Y, respectively - the instruction allows (see also the article Cast iron pipes for sewage: advantages and various installation techniques).

Chamfering is performed in two ways - mechanical and thermal, and the main role in choosing the method is not the price, but the final result. Therefore, the most preferable method can be called mechanical processing, since in this case the processing process is not affected by the chemical and physical properties of the material.

Despite the fact that the mechanical method is more time consuming, there is a major advantage - the complete absence of a thermal influence zone, although heat treatment is much cheaper and can be done with your own hands.

Conclusion

As you understand, flameless cutting of pipes, as well as their processing (chamfering) is much more expensive, but the quality of processing invariably increases. Of course, if you install ordinary plumbing or heating, then high accuracy is useless, but in industrial production it is of paramount importance (see also the article Cast-iron sewer pipes: their types and 4 basic operating rules).