How to apply the flare pipe

If you pay attention to the pipes in your apartment, most of them will have a socket, this also applies to metal and plastic products. They are used for pressure and non-pressure pipelines.

Although their assortment is varied, it is their assembly extension, called a socket, which makes it possible to create a solid connection with one movement.

Flare pipe types

Mounting thickening occurs in such products:

| PVC |

|

| Cast iron |

|

| Ceramic | Sewer fittings with a diameter of 150-600 mm. It has a ribbed inner surface of the mounting bulge and the same shoulder of the socket. Complies with GOST 286-82. |

| Reinforced concrete |

|

| Steel |

|

From this range it is clear that pipes with a bell can be found anywhere, so the methods for sealing them cannot be the same.

Types of installation

Below will be given detailed descriptions of common options. You will learn about their features and practice of use.

Apply glue

This connection is made as follows - the end of one pipe is placed in the socket of another, the combination is made on conical surfaces. The tightness and reliability of the site depends on the adhesive, which is considered to be the main disadvantage of the method (see also the article Pipeline sewer pipe - connection features).

Due to the long-term effect and the influence of tensile forces when the working medium passes through the pipeline, the adhesive stability of this layer weakens.

The installation process also requires the use of a clamping device, which is another feature of the method. Thanks to him, it is possible to create the necessary pressure on the adhesive layer, helping in fixing the knot until the adhesive composition reaches the necessary strength and hardness.

Because of this, the indicator of labor productivity during assembly drops sharply.

We use a snap ring

Reliability in this case occurs due to the fact that the bell-shaped sewer pipe is combined with the smooth end of the pipe. The latter must be inserted with effort into the socket and secured with a retaining ring, which will be pressed against the socket by the union nut.

Due to axial compression, it is possible to firmly fasten the smooth end of the pipeline with a socket to tapered surfaces.

Consider the disadvantages:

- installation difficulty;

- insufficient strength in the event that longitudinal forces and internal pressure of the working medium begin to act;

- The ring has a complex configuration that also does not add lightness when installing it.

Cement coating

To create a tight connection between the inner surface of the socket and the tube inserted into it, it is necessary to seal the gap between them. At the same time it is necessary to ensure that both of them are pre-cleaned of dirt.

Below is a guide:

- Put a resin strand with a rope of rings in front of the socket and drive it tightly into the gap. At the same time, make sure that its end does not get into the knot, for which you will overwhelm it over the ring.

- Caulk a strand in the socket about 2/3 of its depth.

- Prepare the cement mortar and fill it with the remaining space in the socket with a scoop.

- Tamp it tight with a hammer and chasing. Proceed until the tool starts bouncing off the cement.

Tip: use cement M300 and M400, which is mixed with water in a ratio of 1: 9.

- At the end of the process, cover the cement with a wet rag so that it grips better:

- if the temperature in the room is higher than normal, it should be re-wetted from time to time;

- use hot water for mixing in winter, but the sockets should also be heated. At the end of the work the joints must be insulated.

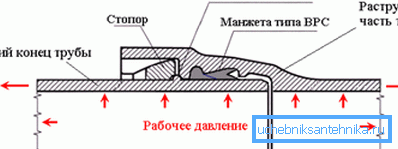

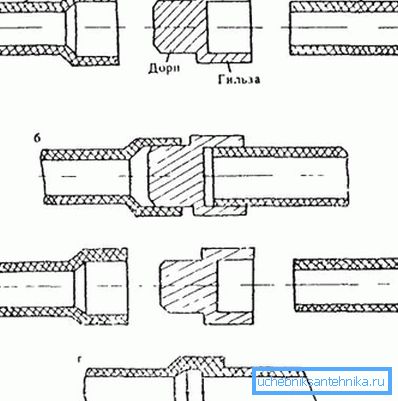

contact welding

This method is implemented for a plastic pipeline as follows:

- products are preheated in an electric furnace or bath;

- the bell is formed with a special mandrel.

Tip: in this case, the outer diameter of the socket must be larger than the inner.

The heating element - mandrel, melts the inner surface of the socket, at the same time, the sleeve melts the outer area of the end face of the reinforcement. For each diameter of pipes and components a separate set is required.

In this case, the working surface of the heating element must necessarily be covered with a fluoroplastic film or a composition that can prevent sticking of molten materials.

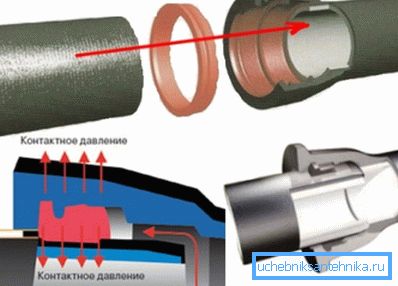

Using a rubber ring

Sewage pipes are connected as follows:

- Clean the chute on the shaped part of the socket.

- Install a rubber ring in it, its price is incomparably small relative to its work, so you should not save on it.

- Apply on the smooth end of the shaped part of the label to which you want to insert it.

- Lubricate the smooth end of the pipe with soapy water and insert it into the socket with a slight rotation to the mark. In this case, note that it should not reach the stop. The gap is necessary so that there is the possibility of free movement of the pipe during its elongation due to the changing temperature of the wastewater.

- Turn the parts after assembly with your own hands to make sure that there is a ring in the gutter; if it is there, you can do it without difficulty.

Conclusion

In this article, several variants of connections were considered by the socket method, in particular, contact welding, with rubber and retaining ring, the use of cement. In each case, one has to not only mechanically perform instructions, but also to understand one’s own actions.

As a result, you should get a reliable hermetic connection that will not fail in an emergency.

The video in this article will help you find additional information on this topic.