How to bend a profile pipe: 4 ways and a few tricks

In the process of work (usually completely unexpectedly), the question may arise - how to bend a profile pipe at home? To date, there are several fairly effective methods, and if you have a certain dexterity, you can cope with the task without referring to the workshop to professionals.

Method 1. Using pipe bending machines

When we talk about the bending of shaped tubes, we often mean the formation of a certain radius from the blank. The larger this radius, the easier our task, since in this way the internal cavity will undergo smaller deformations (see also the article Protective Asmol-Polymer Tape for Pipes).

Note! Curving round and shaped pipes at right angles will not work: a fracture is almost guaranteed. For this purpose, they usually use either a welded joint or special adapters that allow joining two separate segments.

If the need to manufacture arcs occurs fairly regularly, then you should purchase a manual or stationary roll forming machine. It is a device with several rollers that act on the workpiece, giving it the desired shape.

Instructions for working on the pipe bender is quite simple:

- The detail of the desired size is laid in the machine and clamped in the mounts.

- Turn on the electric motor or begin to rotate the handle.

- The working rollers move the pipe axis in the direction of the bend, while simultaneously stretching one of the walls.

- A bending template acts on the opposite wall, giving the blank the desired shape.

- To reduce the deformation of the internal cavity, hydraulic stabilization is often used: the edges of the part are closed with plugs, and a liquid is pumped inward under a small pressure.

To improve the efficiency of all operations, it is necessary to follow these rules:

- The slower we process, the lower the risk of kinks or uncontrolled deformation of parts.

- During the work, you should take into account the limitations on the wall thickness and pipe section relevant for your machine model.

- Thick pipes are better bent in the factory after preheating: by increasing the ductility of the metal, the quality of processing increases.

The price of home appliances of this type starts from about $ 100. That is why to handle a small amount of parts, you can either rent the device for several days, or use the services of a workshop.

Folk remedies

Method 2. Trimming and welding

However, the pipe bending machine at hand is not always. That is why any master should learn in advance how to bend a profile pipe at home with the use of more common tools.

If the integrity of the internal cavity for us is not critical, you can use an angle grinder and welding machine:

- We apply marking on the part, highlighting the section along which the bend line will run.

- From the inside, with the help of a grinder with a cutting disc, we make several cuts of at least 3/4 of the section.

- Holding the ends of the part, we form a bend.

Tip! if necessary, the excess metal cut the same grinder.

- Fix the workpiece in the template and weld the edges of the cuts.

- After the metal cools down, we change the grinder disc to the grinding wheel and polish the treated surface.

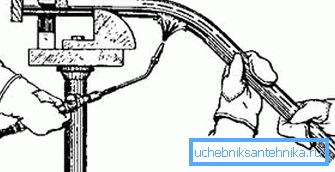

Method 3. Internal spring

If preserving the integrity of the walls is fundamental, then in order to accomplish the task before us, you need to make a special spring with your own hands:

- We take steel wire with a diameter of 4 mm. The thicker the pipe walls, the stronger the wire should be.

- Using a full-bodied steel block, we wind a square spring. The size of the side of the square is chosen in such a way that the resulting structure easily passes into the internal cavity of the pipe.

- Lay the spring in the bend area, then heat the part with a blowtorch.

- Using a template or a round disc of a suitable diameter, we form an arc. At the same time, the spring inside will protect the part from fracture and preserve its profile.

This technique is quite time consuming, since the manufacture of springs takes a lot of time and effort. On the other hand, the elastic insert can be used repeatedly, so that the described method is quite suitable for large-scale work.

Method 4. Filling with sand or water

If at hand there is no suitable steel wire, and the need to manufacture the arc from a tubular billet is quite acute, you should use one of the techniques that involve internal filling.

Liquid can be used as a filler:

- Before bending a profile pipe made of copper with thin walls (sometimes they are used in heating systems), we fill the cavity with water, tightly closing both ends.

- After pouring, we take out the product in the cold or put it in the freezer. We wait until the water completely freezes.

- Using a blank or template, we make a bend of the pipe, after which we take out the plugs and drain the water.

In the warm season, as well as when processing thick-walled blanks, we replace water with sand:

- Sift the material, removing all contamination, and then thoroughly calcined on fire.

- We plug one edge of the blank with a wooden stopper.

- We pour dry sand into the cavity, compacting it thoroughly by tapping it on the ground or a workbench.

- Install the cork to the other end of the part and perform bending. If you do not hurry, the sand due to the maintenance of internal pressure will not allow the formation of an internal fracture.

Conclusion

If you at least periodically work with metal, then you need to be aware of how to bend a profile pipe without a pipe bender. Of course, all the described methods will not be able to fully replace high-quality professional equipment, but in a critical situation they are able to come to the rescue, allowing to solve the problem as quickly as possible (see also the article Deflector on a pipe - what it is and why it is needed).

If you want to get acquainted with the processing technology in more detail, we recommend watching the video in this article.