How to bend a stainless steel pipe

During construction, repair and installation works, pipes are used for laying sewage systems, gas pipelines, plumbing, ventilation, sewage, etc. Depending on the place of operation, pipes of different materials, different thicknesses, diameters and lengths are used. It is not always possible to use the knee or adapters. In such cases, you have to bend the pipe, as a result it can be damaged or even ruined. Since such a material as stainless steel has sufficient strength, has a long time of operation and is not affected by moisture, it is often used during installation. Therefore, in this article we will discuss how to bend a stainless steel pipe.

The process of bending metal products can be divided into two types. Temperature, when the workpiece or its part is heated or cooled, followed by bending. Mechanical, when the workpiece is applied with a certain force, using special devices or manually bending it. It is worth noting that stainless steel is relatively tech-friendly material and difficulties do not usually arise at work.

Stainless steel pipes should not be bent with preheating (for example, a gas torch or a blowtorch).

Bending as a negative factor

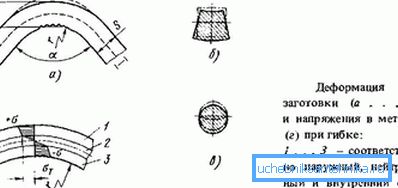

Pipe bending is a negative factor for performance. There are various disadvantages, depending on the material, bending angle, device and method of bending, internal diameter and thickness of the material. The negative effects include:

- change in bending radius during operation under the influence of thermal expansion or contraction and mechanical action, as a result of which a spring effect is observed;

- reducing the thickness of the outer wall at the bend;

- the appearance of sharp kinks or folds in the form of an accordion on the inner wall of the bend;

- ovalization? the change in the shape of the pipe and the appearance of the oval lumen;

- increased exposure to corrosion on the inside and outside of the bend.

When a substance passes through the internal cavity of a pipe, special pressure falls on the external wall, therefore, when mounted in places with high-pressure leaks, the use of a knee, thickening or a pipe with thicker walls is recommended. The resulting ovalization also negatively affects the pipes with the rapid movement of fluid flow. In such places, a narrowing along one axis and expansion along the other occurs, which, in turn, also increases the pressure on the external wall of the bend. You also need to take into account the ovalization when laying pipes in narrow places, as its width at the bend increases.

There are two ways to prevent ovalization and maintain a round shape during cold bending. First, support the walls from the inside using an internal stop. Second, support the walls from the inside as well as from the outside, using an internal and external restraint. The internal limiter can serve as sand, rubber, water, resins, or low-melting materials that are thoroughly rammed into the pipe. The main thing is to securely close the openings of the pipe so that when the pressure increases during bending, the filler does not fall out. If possible, it is recommended to tightly brew the holes in the pipes.

When using the second method, the integral indicators are slightly higher, but this requires special mechanical elements or tanks, which are usually used in the industrial manufacture of pipes. If you apply a more rigid and solid inner filling, the more round shape of the lumen will remain, therefore they are used more often. But when using elastic fillers, the outer side is less stretchable.

Bending methods

In production, when stainless steel pipes have to be bent, cold bending is usually used because of the highest profitability indicators, and in cases where hot bending is necessary, it is often advantageous to just immediately pour out the desired shape. Therefore, the following are the methods of cold bending, especially since most technologies are not very different from the hot method.

Bending using two supports

The workpiece is placed between two supports in such a way that the first support holds and the second one is carrier. When exposed to a screw or hydraulic press or ram, then the second pillar bends. This method can bend pipes with a diameter of up to 350 millimeters. The equipment has sufficient simplicity and can be used directly in the places of installation.

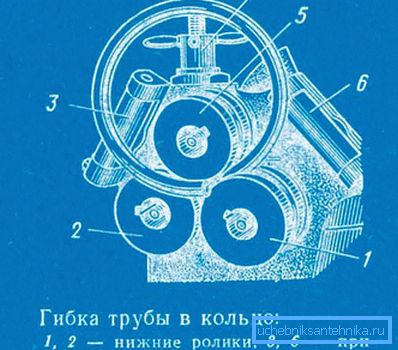

Rolling

This method is used when you need to get a ring or a spiral from a pipe of small diameter. The workpiece with the help of mechanical fasteners and pusher moves through the rotating rollers, then it acquires the necessary curvature.

Bending by rolling

In this case, the workpiece is fixed and rolling out in certain places with the help of special balls. A similar process can occur both from the outside - wrapping, and from the inside - rolling. As a result, the tube acquires a triangular shape with rounded edges.

Winding bending

This method is widely used in industrial production due to the relative simplicity with low energy costs and the output of quality products. In this case, internal filling is used, most often it is a metal rope with a diameter of 0.1–0.5 mm smaller than the internal diameter of the workpiece. When bending the rope, it can leave a mark on the inner surface of the pipe; therefore, cables of thin woven metal fibers of non-solid grades are used. Also, when using this method, lubrication is required between the rope and the inner surface, which is usually engine oil or anti-corrosion soap emulsion. You can bend pipes with a diameter of 10 to 425 millimeters in different planes. Therefore, for large diameters, the cable is not used, but if possible it is replaced by a loose or liquid substance.

Bending with running

The method consists in that a rolling roller moves around a roller or a support of the required dimensions, between them a workpiece lies and a bend is obtained. In a similar way, you can work with pipes with a diameter of up to 150 millimeters with thick walls.

Bending with internal hydrostatic movement

In this case, a liquid is pumped into the pipe, usually water or oil, and tightly closed with plugs. Subsequently, pressure is created inside and the workpiece becomes more malleable for mechanical bends.

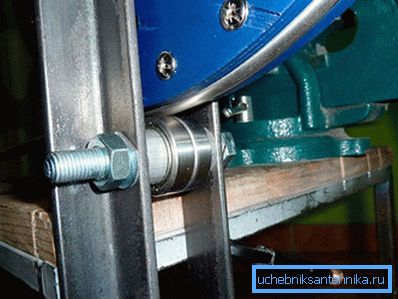

Manual mode

In the conditions of home construction it is better to use special pipe benders. But it is necessary to consider the possible undesirable consequences described above.

Tip! For less lumen deformation, internal fillers should be used.

We also recommend that you read the articles that describe the methods of bending other pipes:

- How to bend a copper pipe.

- How to bend a polypropylene pipe.

- How to bend a plastic pipe.

- How to bend a profile pipe at home.

Video

This video shows how to bend a stainless pipe on an improvised pipe bender:

We are beating the pipe with ice inside and without it. In this video you will see the difference: