How to bend pipes: do without using a special tool

Surely, many home masters have repeatedly encountered the need to bend all sorts of pipes of small diameter over a certain radius or to give them the necessary rounded configuration. On an industrial scale, special equipment is used for these purposes, but in this case the question is different: how to bend the pipe without a pipe bender at home?

Independent pipe bending

In order to help the reader deal with this issue, this article will discuss several ways to bend pipes of circular and rectangular cross-section made of various materials (see also the article Deflector on a pipe - what it is and why it is needed).

Also, a detailed instruction will be presented here, in which all stages of this operation are described step-by-step using a set of ordinary household plumbing tools.

Steel pipe bending

Steel itself is a fairly rigid material, but when heated to a high temperature, it becomes more plastic, which makes it possible to give almost any desired shape to steel products. In order to bend an arc or a circle from a steel round pipe with your own hands, in addition to the usual plumbing tools, you will also need a gas burner.

For this you need:

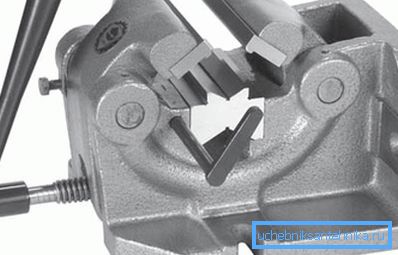

- Secure the steel tube in a vice. In order not to crush the walls, it is necessary to pre-insert a metal bar of a suitable diameter in the clip section.

- Using a gas burner, heat up the area of the future bend until the characteristic color of the metal is bright red.

- With a short gentle blow of the hammer, to give the preheated part the necessary configuration, controlling the bending radius according to a pre-made pattern.

After cooling, the finished part will retain its shape, and the metal will again acquire the same rigidity and high mechanical strength.

Tip! The described method cannot be used to bend steel galvanized pipes, since zinc will burn out when heated to a high temperature, as a result of which its anti-corrosion properties will disappear.

Bending of non-ferrous pipes

Non-ferrous metals such as copper or aluminum have a high ductility, but due to insufficient strength, the opposite walls of the pipe may not withstand multidirectional loads (compression and tension), as a result of which they break or collapse.

In order to evenly distribute the local internal stresses of the material, they use simple technology of bending thin-walled pipes made of non-ferrous metals.

- Before bending an aluminum pipe, it is necessary to choose a suitable steel spring so that its diameter approximately corresponds to the internal diameter of the pipe, and its length is not shorter than the length of the bend section.

- Tying a strong long wire to the spring, insert it inside the pipe, placing it approximately in the center of the supposed arc.

- The part should be gently clamped in a vice, without making great efforts, in order not to crush thin walls made of soft material.

- Using a gas burner, warm up the place of the future fold to the temperature at which the paper begins to smolder.

- Holding the free end of the pipe with the gloved hand, bend the heated part along the required radius.

- After the part has cooled down, remove the spring from the inner lumen of the tube using the left end of the wire.

Tip! Non-ferrous metals have a high thermal conductivity, so when working with a heated part, care should be taken not to get burned.

Bending metal pipes

There is a special tool for working with metal-plastic plumbing, but its price is not worth buying a plumbing pipe bender for a home tool collection. Metal pipes are quite plastic, so they can be given any desired configuration. Arcs with a large radius can be bent by hand, performing short smooth movements and gradually giving it the necessary shape and angle of bending.

For the manufacture of an arc with a small radius or a 180 ° reversal, you can use a more complex, but at the same time effective method.

- Cut thin copper wires in such quantity that they can completely fill the inner lumen of the metal-plastic pipe.

- Insert them inwards so that they completely fill the tube at the bend and at the same time all their ends remain outside the end of the tube.

- Making a sufficiently large effort with your hands, to give the future detail the necessary shape, and then remove all the wires one by one from the internal lumen of the tube.

Tip! It is recommended to use copper wires without PVC insulation as a filler, because it can jam and hinder their further extraction after work is finished.

Bending of profile metal

Plastic deformation of steel and aluminum profiled pipes is complicated by the presence of side faces, which are stiffeners, therefore, require additional efforts at work.

In order to maintain the correct profile of the final product, and to prevent wrinkles and metal breaks, the internal cavity must be filled with dense movable material.

- For a pipe cut, prepare two wooden, rubber or plastic plugs, which should fit tightly into its internal lumen.

- Insert a plug from one end of the pipe, then completely fill the entire internal volume with sand from the second end, then insert a second plug into the other end.

- In winter, instead of sand, you can use water. Pouring it, and installing the plugs, you need to move the part to the balcony until the water completely freezes in the entire internal volume.

- After that, you can proceed to the formation of the arc with a hammer or rubber mallet, holding the part in a vice, or putting it on the edge of a strong stable support.

This method can also be useful for those home craftsmen who do not know how to bend a stainless steel pipe or galvanized ferrous metal.

Conclusion

After reading this article, it becomes clear that there are many ways that can help the home craftsman to make a part of the plumbing or a piece of metal pipes in the home, even without special equipment.

For more information on the subject of interest, you can watch the video in this article or read similar materials on our website.