How to bend the pipe yourself: practical tips and tricks

In this article, we will talk about how and where to bend the pipe, so that it does not crack and has been fully exploited for a long time. The topic of the article is relevant, since today a wide range of pipes made of various materials is on the market.

Some materials withstand the deformation and subsequently do not crack on the bend, while other materials are not designed for such loads. But almost all the metal, necessary for the construction of pipelines can be bent with your own hands, using special tools.

What can be bent and what not

Many compatriots are wondering whether polypropylene pipes can be bent and how to do it correctly (see also the article Shell for pipes: we study the features and installation technology).

Consider what materials are subject to mechanical deformation without prejudice to subsequent operation, and which are not.

- You can bend almost all metal, including aluminum, copper and steel pipes of different diameters. It is more difficult to change the configuration of stainless steel products and similar hard alloys.

For the correct deformation of all metals, without exception, a special machine is needed for bending pipes. The use of a special machine will not only ensure optimum quality of the bend, but also allow you to complete the task with minimal physical effort.

Important: Without a special machine, you can do, changing the shape of the metal. Products made from this material are easily deformed by hand, but in order to keep the cross section at the bend area constantly round, a special spring is used.

- Do not bend pipes from various polymeric materials that are not reinforced with a metal layer.

Some plumbing fixtures from the economy of fittings preheat polypropylene with an industrial dryer and bend to the required shape. It is inexpedient to do this, because due to the deformation in combination with the heating, the bent plastic pipe will have an uneven wall thickness on the outer and inner radius.

As a result, the operation of the constructed water supply system will be short-lived, since under the pressure of a liquid medium, cracks will appear in a thin wall with time.

Important: Some polypropylene manufacturers, such as Ekoplastik, allow the pipes to deform when heated with hot air, taking into account the minimum bending radius equal to 8 pipe diameters. Therefore, before making a decision about the relevance of the bending works, familiarize yourself with the recommendations of the manufacturer given in the instructions.

Choose the right tool

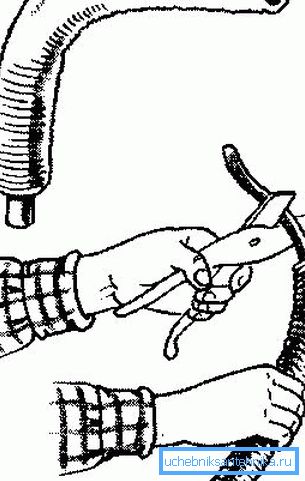

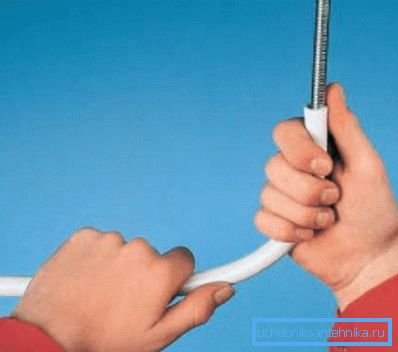

Spring - an effective tool for working with metal. The springs on the market are of two types: external and internal. Both that and other type of the tool are distinguished by reasonable price. The tool must be selected in accordance with the external or internal diameter of the pipe.

The fixture is made of polished steel. The smooth surface of the coils allows you to remove the spring from a bent pipe. The use of a spring allows for the same cross-section diameter throughout the fold.

The pipe bender is a wide range of machines or devices designed to deform the metal, taking into account the desired angle and bend radius. Devices are actively used in the construction of pipelines for various purposes of various configurations and sizes.

Classification pipe benders

All modern pipe benders meet the following requirements:

- possibility of bending at an angle of up to 180 degrees;

- the ability to work with pipes made of various materials, including aluminum, copper, steel and polymer compositions.

Such equipment in accordance with the type of drive used is divided into the following categories:

- Manual modifications, As a rule, they are used for work with small-diameter pipes. The device is driven by a collar, to which a substantial muscular effort is applied.

- Hydraulic modifications - This is the best choice for working with pipes whose diameter does not exceed 3 inches. Operation of hydraulic devices allows you to work with pipes without excessive physical effort. Mobile and stationary hydraulic pipe benders are on the market.

- Electromechanical modifications represented on the market by universal devices designed to perform high-precision bend. The main advantage of such pipe benders is the ability to work with thin-walled metal without the threat of damage.

In accordance with the bending method and the configuration of the working part, the tool can be:

- Crossbow, where, as a deforming element, a replaceable metal guide form is used, which is chosen for a certain diameter of pipes.

- Segmental, where the metal is drawn by a special segment that wraps the pipe around it.

- Dornov, where work with rolled metal is carried out both from the external and from the inside of the pipe. This feature allows you to use the device to change the configuration of thin-walled pipes without the threat of metal rupture or the formation of folds on the inner diameter.

Pipe bending technology

The instruction for changing the configuration of pipes by means of an external spring is as follows:

- The spring is put on the metal-plastic pipe at the place of the alleged bend;

- Then the pipe is captured with both hands at a distance of 20 cm from the spring and bends until the desired angle is obtained;

- After the desired angle is obtained, the spring rotates around its axis and is removed.

The use of an internal spring is different in that the device is inserted from the edge of the pipe, where it can then be pulled out.

The bent end of the pipe can be obtained using a pipe bender. In this case, the device, in accordance with its modification, is adjusted to the required parameters. Then the pipe is inserted into the receiving gap and the device is driven by one or another drive.

Conclusion

Bent pipe according to GOST is an integral attribute of the construction of pipelines for various purposes. That is why it is so important to choose the technology and the appropriate tool through which it will be possible to ensure high quality of the bend and the absence of damage to the pipe walls.

You can find more useful information by watching the video in this article.