How to calculate the area of the pipe outside and inside

Most likely, you had to deal with the problem of calculating the surface area of the pipeline and its internal section. This usually helps the formula, known to many of the school course, albeit forgotten. In this article we will learn how to calculate the area of the pipe and its diameter correctly.

What is it necessary to know

Below we consider the situations where these parameters usually always need to be considered in the work:

- Knowledge of the formula area will be useful when calculating the heat transfer of a heated floor or heating register.Data can be obtained on the basis of the total area, which gives the air in the room heat from the working fluid of a certain temperature.

- The second option is the reverse situation, which is also common.. Especially if you need to calculate the heat loss over the entire length of the pipeline to the heating device. When calculating the number and size of convectors, radiators and other devices, the instruction requires you to know exactly how many calories they can produce. Data is determined by taking into account the surface area of the water transporting pipeline.

- If you know how to calculate the surface area of a pipe, you can purchase the right amount of insulation.. Very often, the length of the heating line is tens of kilometers, so accurate data will help companies to save impressive funds.

- Another point - the cost of painting or anti-corrosion coating, the price of which is sometimes impressive. In this case, knowledge will accurately calculate the required amount of material. In addition, it is possible by indirect methods to determine the negligence of the contractors, if the cost of 1 m2 surfaces will increase substantially.

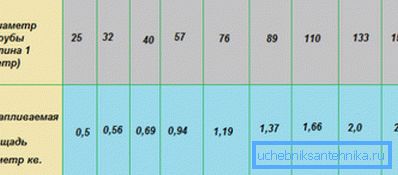

- The calculation of the pipe area (cross section) will allow you to find out the maximum throughput. Of course, it is possible to simply establish a obviously larger diameter right away, however, with large investments in construction sites, this indicator plays a significant role in cost overruns.

Tip: remember, although in a private house, budget overruns when installing a pipe will be a little more for a step, but you will lose on heat losses, since the larger the surface of the object, the more heat it gives per unit of time.

Do not forget that when the hot water tap opens, the volume of liquid in the water supply system cools off purposelessly. The large diameter of the pipe accumulates a large amount of water that will stand in it, so you will spend more heat to heat the room.

Tip: a pipe square calculator can be found on our website, as well as on the websites of specialized companies.

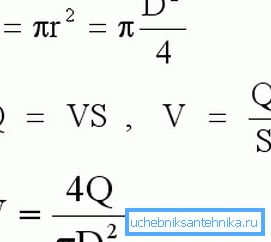

How to calculate the cross section

- It is necessary to calculate the area of the circle and take away the thickness of the walls.

- The formula is as follows: S =? (D / 2-N)2.D - diameter, N - wall thickness.

Tip: do not forget that in pressure water pipes, the working fluid fills the entire volume. In the self-flowing sewage system - the flow basically wets only part of the walls, so the pipe has less resistance than in a fully filled one.

For hydraulic calculations of the latter and introduced the concept - the living section.

Surface calculation

A geometric problem that you often met in class when you needed to know the surface area of a cylinder, but a pipe is what it is. To find out the desired figure, you need to know the circumference and the height of the cylinder (in our case, the length of the pipeline).

The formula for the circumference is Lokr =? D, surfaces - S =? DL, where L is the length of the pipeline, and D is its diameter.

For dyeing, you can use this formula directly, but if it is necessary to carry out thermal insulation work, you will need a little more material, since it is thick. In addition, during the process, mineral wool is laid with some overlap of cloths.

Calculate the inner surface

Not experts will ask the question - why do you need to know this parameter? Specialists will answer - for hydrodynamic calculations, in order to know what area has contact with water during movement through the pipes.

There are several associated nuances with this parameter:

| Diameter | The larger it is, the less the roughness of the walls affects the movement of the working fluid. If the pipeline has a large diameter and its length is small, the resistance of the pipe can be neglected. |

| Roughness | This parameter is of great importance for hydrodynamic calculations. For example, a rusty steel inside a water pipe and a smooth polypropylene one differently affect the speed of the working fluid. |

| Constancy of internal diameter | Steel and cast iron products change their internal area over time due to corrosion and mineral deposits. Because of this, the flow passage is reduced. |

Tip: do not forget that the steel water supply for cold water will reduce its permeability within 10 years by almost 2 times.

In this case, the calculation formula is S =? (D-2N) L, where N is the wall thickness, L is the length of the pipeline, and D is its diameter.

Conclusion

This article only allowed to refresh the formulas that give an idea how to calculate the area of the pipe and its surface. Strangely enough, but this knowledge often helps to solve emerging problems during home repairs. The video in this article will help you find additional information on this topic.