How to choose a machine for welding polypropylene pipes:

To save on repair and construction work, many decide to independently master the technology. If there is a desire and at least elementary building skills, it will not be so difficult. A rather laborious and complicated process is the replacement of engineering communications. So, for welding polypropylene pipes, which have long been supplanted by iron pipes, a special soldering iron is needed. Before you go to the store to buy a machine for welding polypropylene pipes you need to find out the basic rules for its use.

Welding process

First of all, you should be familiar with the main types of welding:

- butt;

- clutch;

- bell-shaped

The first option is considered the most economical and simple, because apart from the welding machine, nothing else is needed. The second and third options involve the use of fittings and couplings. The principle of operation of the apparatus for plastic pipes resembles the principle of operation of a simple soldering iron. The contact surfaces are heated to the set temperature, and the connection occurs in one of the above ways.

Tip! According to experts, the fastest and most accurate is butt welding. Fastening the ends of the pipes occurs under pressure. As a result, the seam gets the same strength as the pipes themselves. The selected equipment should provide heating in 260? WITH.

Main types of welding equipment

To determine which welding device is better, it is necessary to consider all the options. So, conventionally, the devices are divided into two large groups:

- The mechanical apparatus is used when necessary to apply a large force to precisely align the joints or when soldering large-diameter pipes.

- Manual is a great option for newbies. It can be used to connect pipes of different diameters.

So, the majority of masters chooses the manual device for work, but thus one more classification is considered. Models differ in design:

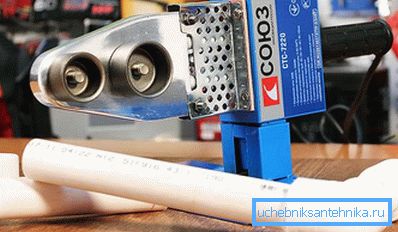

- Sword-shaped (in common language - iron). The steam nozzle is installed through the holes. Such models are presented in a large assortment.

- Cylindrical. Special nozzles are used. In most cases, professionals and specialists work on such equipment.

Tip! Sword-shaped apparatus is the most common. It includes: a heating element, a handle and a thermostat. The ends of the plastic pipes are fixed in special holes of the heating plate.

Device

The mechanical welding machine is presented in the form of a support frame, which is equipped with a hydraulic unit and an instrument unit. On the sides there are two captures in the form of half-rings. Between them it is necessary to establish inserts and centerings. The inner diameter must correspond to the diameter of the polypropylene pipes. In the role of the heater is a metal disk, inside of which the heating elements are mounted. Temperature control is carried out using a thermostat.

All models of manual welding machines have small dimensions, which makes it easy to transport and carry out work in any room. The principle of operation is similar to a simple iron. The only difference is the appearance of the structure. As already mentioned in the previous section, in such models the main element is the heating element. It is very important that the welding elements have a non-stick Teflon coating. Due to this plastic will not stick to the surface.

Tip! The quality of pipe welding will depend on the flatness and smoothness of the ends. In the mechanical apparatus, the alignment process is performed by an electric pick-up.

We take into account the technical characteristics

It is necessary to consider the technical characteristics and performance models. This will not make a mistake when choosing and buy a quality tool:

- Expediency. Selecting a complete set is necessary depending on the complexity of the work. The same applies to the cost of the welding machine. For example, to connect several plastic pipes, it is enough to buy a manual and low-cost model. If you plan to perform bulk work, it is better to immediately purchase a full-fledged, well-equipped device.

- Power. The heating rate will directly depend on the power of the installed heating elements. It should be borne in mind - the higher the power, the higher the cost of the device. If the equipment is selected for domestic purposes, it will be quite enough welding with a small capacity. Also, the power is calculated from the area of the heating element.

- The diameter of the pipe. This criterion is also worth considering. For domestic purposes, suitable manual models. But if you need to weld polypropylene pipes of large diameter, these devices do not fit, you must immediately proceed to consider the purchase of professional equipment.

- Temperature mode. In professional models, higher temperatures are established, and their stability is demonstrated for a certain time. In the case of manual welding, this is not true.

- Equipment. Despite the high cost of fully equipped equipment, it will be several times better than a simple soldering iron. So, the full set includes nozzles of various standard sizes. The list of additional tools and devices includes: a measuring device (tape measure), a stand, a cutting tool (cutter), and hand protection gloves. The standard set includes: a welding machine, a key for nozzles and a detailed guide to use. The professional sets should also include attachments, accessories, and also a case for storing all items.

- Nozzles For convenience, install immediately 2 nozzles on both sides. The best material for the production of nozzles is metallized Teflon.

- Stand. To fix the welding machine, you need to install it on a special stand. The more massive it is, the less chance of sticking of pipes.

Tip! During the work with polymeric pipes with a diameter more than 10 cm, the power indicator has to be from 1,5 to 2 kW. In everyday life, most often small pipes (diameter up to 63 mm), therefore, a power of 0.85 kW is enough.

There will be no special difficulties in choosing a welding machine for connecting polypropylene pipes, provided that this information is guided. The choice in favor of a particular model will directly depend on many indicators. Also, do not forget about your own safety: the relay will not allow overheating, and thanks to the insulating material on the handle, people will not get burned.