How to choose a pipe for heating

The development of modern technologies has made it possible to create a huge choice of materials for pipes of heating systems with different properties that are appropriate to apply in specific situations in order to obtain maximum impact. They differ in both technical and physical properties. Technical - they differ in size, method of attachment and operating conditions. Physically - they have different thermal conductivity coefficient, they are designed for different temperatures of the liquid, pressure, etc. In addition, one should be guided by the thermal calculations of the system so that when transporting hot water, heat losses are minimal and heat dissipation occurs only in a heated room.

What are the requirements for heating pipes?

- Pipes must withstand water pressure in the system. This is especially true of the main heating systems, where the pressure can reach hundreds of atmospheres.

- Installation should be convenient in specific conditions depending on the type of fastening to the walls.

- Depending on the external or internal method of installation, the pipes must have a protective anti-corrosion coating or decorative.

- Resistance to high temperatures. Metal thin-walled and plastic pipes have a certain threshold of temperatures, above which they lose their properties and become unsuitable for use.

- Ensuring long life.

Types of pipes used for heating

At present, the following types of pipes are used for heating systems according to the material of their manufacture:

- Steel.

- Stainless steel.

- Plastic.

- Metal-plastic.

- Made from non-ferrous metals (copper and aluminum-based alloys).

All of the above materials have different properties and temperature conditions of operation, therefore, how to choose pipes for heating, it is necessary to decide the designers of heating systems.

Steel

Steel pipes are made on the basis of iron-carbon alloys with additives of dopants, which allows to obtain high strength and reliability, resistance to high temperatures and enormous pressures. Steel, even with small sections, is resistant to mechanical stress. A small degree of expansion during heating eliminates the use of compensators. However, due to the effects of moisture, they easily rust, therefore, when laying the pipeline externally, it is necessary to apply protective coatings. In addition, high-quality insulation of pipe walls will be needed, since steel dissipates heat, and significant losses can occur.

During installation, difficulties may arise in the following situations:

- A significant weight of pipes requires a rigid attachment, which does not always have an aesthetic appearance, especially if the walls are made of adobe or are frame structures. Therefore, to mount them in rooms with modern decoration will not work.

- If you wish to install these pipes in the walls, you need to bear in mind that this is unprofitable, since they can rust there and leak will appear. It is not possible to check the condition of the pipes in time.

- Make a high-quality welded joint at close proximity to the wall will not work.

- The organization of pipe joints is quite a laborious task, because if a threaded connection is chosen, threading will be required or, if welded, the use of a welding machine and experience in such works are chosen.

Despite the presence of negative properties, steel pipes are widely used due to the low cost of materials and strength characteristics.

Tip! The most appropriate scope of application are the main pipelines, where there is always space for their installation. In this case, pipes with a large cross section and thick walls are used, which have a long service life and provide good throughput.

Stainless

Stainless steel pipes are a worthy competitor to steel, as they have all their advantages, and also have anti-corrosion protection. Due to the smooth inner surface and the absence of oxidation reactions, they are able to not clog and ensure the greatest possible flow of liquid. The range of their application is practically unlimited, except perhaps by their high cost.

Such pipes have good heat transfer and therefore can be used in heating batteries and floor heating systems. They can be mounted in the wall without fear of the possibility of emergency situations. They, as well as steel, have a low coefficient of thermal expansion, are not exposed to the effects of pests and fungi.

Polypropylene plastic

Plastic pipes are lightweight, durable and have a long service life. Installation does not cause any difficulties, as the pipes are well processed and connected into a single monolithic structure using welding technology. Since pipes do not corrode, rust and scale will not build up inside the pipes. They have a very aesthetic appearance and can be used for any room design. However, they have significant drawbacks:

- do not bend, which is sometimes critical when mounting;

- cannot withstand high temperatures (above +95 ° С, depending on the material), therefore they are not suitable for highways;

- have a high coefficient of thermal expansion, as a result of which adapters to metal pipes are the most emergency place;

- break under mechanical stress due to insufficient strength.

Plastic pipes can be reinforced with fiberglass, aluminum foil, which ensures the functionality of the heating system at temperatures up to 110 ° C and makes them more durable.

When viewed from an economic point of view, polypropylene pipes are more profitable due to quick installation, low cost and environmental friendliness of the material.

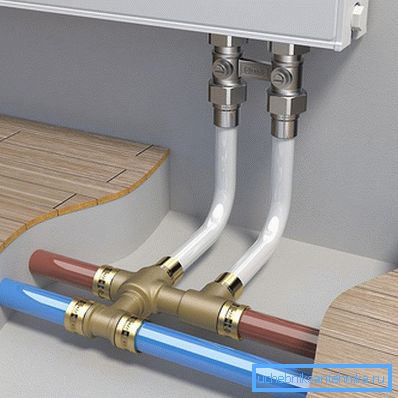

Metal plastic

Metal pipes are a polyethylene pipe, covered with a layer of aluminum, and from the outside - a plastic protective layer that performs a decorative function. However, if we compare a pipe with a plastic one over its outer diameter, the metal-plastic one will have walls that are much thinner without loss of strength and have a large carrying capacity. They have all the advantages of plastic pipes.

For the connection of such pipes press fittings are used, which allow you to make a strong and compact connection. In addition, for the connection using glue on a polymer or metal base.

Copper

Pipes made of copper are practically ideal for the heating system: they are able to withstand high pressures, are not susceptible to corrosion and are resistant to high temperatures up to 500 ° C. But they have high thermal conductivity, and therefore their installation will be advantageous in heated rooms to reduce the level of heat loss. They are light and well bent and processed.

They are connected using fittings or using press fittings. Their welding is a rather complicated process that will require a lot of experience and a special welding machine. Another disadvantage of such pipes is high incompatibility with other materials, since copper has a lower coefficient of expansion than, for example, fittings made of bronze, steel, brass.

Tip! Copper pipes will be the most expensive of all possible, but also the most reliable and durable.

Before choosing pipes for heating, it is necessary to understand what technical conditions of operation are required to provide, as well as to consider installation requirements. Therefore, it is necessary to carefully select the pipes so that the heating system works with maximum efficiency.