How to choose a pipe for water supply in a residential house

Many homeowners during the construction or repair of their own homes are thinking about the question: what is the best way to use pipes for internal distribution of the water supply system? In the old days, when there was no other alternative, all communications inside the building were made of steel water pipes, but now they are replaced by more modern and practical propylene pipes for water supply, which are widely used in construction, due to their reliability and high operational qualities.

Overview of water pipes

In order to substantively examine the question of the right choice of pipe material for a plumbing system in a residential building, later in this article the most common types of pipes for plumbing are presented, which are manufactured according to modern quality standards.

Also, for familiarization with the reader, a simple instruction will be offered, in which it is written in accessible language how to calculate the diameter of the pipes for the domestic water supply system.

Steel pipes

Starting to talk about what are water pipes, it should be noted that, until recently, steel was the only material suitable for the manufacture of seamless and electric-welded water pipes. Due to high strength, heat resistance and good protection from mechanical damage, nowadays steel products are also used for laying underground, external and sometimes internal communications. For example, pipes for fire water supply, according to the requirements of fire safety rules, should be made only of steel.

However, despite these positive qualities, steel pipelines have a large number of disadvantages.

- The most significant drawback of all steel products is the very weak resistance of iron to moisture.. Despite the anticorrosion treatment, at the slightest violation of the protective coating, water, falling on the surface of iron, causes its corrosion, which over time leads to the complete destruction of the metal.

- Foci of corrosion on the inner surface of the walls accelerate the formation of lime deposits, which gradually narrow the inner lumen of the pipe. This leads to a decrease in throughput, and as a result, to complete blockage of individual sections of the pipeline.

- During underground installation, iron reacts with soil electrolyte, resulting in soil corrosion, which leads to frequent breakthroughs of the water supply network..

- The relatively high price of ferrous metal and the need to use energy-intensive welding equipment to connect parts of the pipeline, now makes it inappropriate to use steel pipes when installing water supply networks.

In some cases, where the use of metal is mandatory, stainless steel pipes for water supply can be used, which practically do not have the disadvantages described above, but they are very expensive.

Tip! The most effective way of anticorrosive protection of ferrous metal is to coat its surface with a thin layer of molten zinc using the hot-dip galvanizing method. Such processing can significantly increase the durability of steel water supply.

Metal pipes

In fact, any metal-plastic water supply system is a three-layer composition based on an inner pipe made of cross-linked low-pressure polyethylene, on top of it is a reinforcing layer made of thick aluminum foil, and outside there is a continuous protective coating made of cross-linked polyethylene.

In the end, all these materials, compressed and bonded to each other with special glue, form a rigid, but at the same time moderately flexible pipe, which is often used for installation of internal plumbing communications.

This material, against the backdrop of old metal water pipes at one time was widespread due to the following distinctive qualities:

- Aesthetic appearance of the pipeline and connecting fittings, as well as the absence of the need for annual rust removal and protective painting.

- A simple and affordable do-it-yourself installation system using threaded and crimped bronze fittings for pipes with expandable brass liner that does not require the use of special tools.

- Due to the flexibility of the material, metal-plastic pipes make it easy to bypass small obstacles and also use fewer fittings and connecting corners for the installation of the plumbing system.

Like any material, metal-plastic products are also not without certain disadvantages:

- Due to the shrinkage of polyethylene, fittings threaded connections weaken over time, and therefore require regular testing and periodic tightening.

- Some manufacturers install the inner insert of aluminum foil is not a solid design, but in the form of a twisted helix. Under the action of bending loads, the turns of the spiral diverge, which leads to a deterioration of the reinforcing qualities of the metal, and as a result, to a significant decrease in the maximum allowable working pressure in the system.

- With careless handling metal pipe can be quite easily pulled out of the threaded connecting fitting that, as a rule, leads to unpleasant consequences in the form of a flood.

Tip! In order to circumvent significant obstacles on the wall or in the corners of the room, as well as to lay the pipeline in hard-to-reach places, a special corrugated water pipe is used, which has high flexibility and is able to withstand the maximum water pressure in the system.

Polypropylene pipes

The most reliable and durable material for the installation of water supply systems in a private house or residential apartment are water pipes and fittings made of polypropylene.

- They have high strength, are absolutely not subject to corrosion, are not afraid of exposure to low and high temperatures and do not require additional maintenance during operation.

- Due to the absolutely smooth inner surface of the walls, they create minimal resistance to the movement of water.

- Polypropylene has a good sound-absorbing ability, which significantly reduces the noise level in the room.

Having stopped the choice on similar system of water supply, it is necessary to keep in mind some features of installation of polypropylene pipes, and also shutoff and connecting fittings.

- To ensure a reliable and tight connection, all components of the water supply network must be welded to each other using a special welding machine for polypropylene fittings.

- Polypropylene has a sufficiently high linear coefficient of thermal expansion, therefore, with open installation of the pipeline, temperature deformation compensators must be installed at certain intervals.

- When flush-mounted, to compensate for thermal deformation, a shim of resilient porous material is laid in the gut along the entire length.

Tip! When installing a plumbing system, it is important that the outer diameter of the plumbing pipe exactly matches the inner diameter of the connecting fitting.

Selecting the size of the inner section

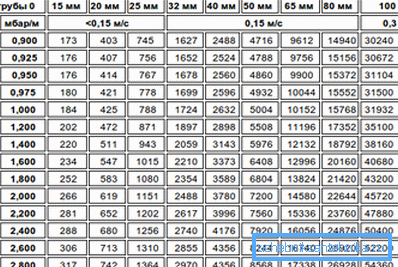

Having decided on the material for home plumbing, an equally important task is to choose the internal diameter of the water pipes. For these purposes, special programs are used, as well as tables in which you just need to substitute the known values of the working pressure and the internal diameter of the pipe, and at the output get the throughput of the entire system.

Conclusion

After reading this article, every homeowner will be able to make the right decision for himself which pipes for a water supply system are best to use depending on certain specific conditions. For more information on this issue, you can watch the video in this article or read similar materials on our website.