How to choose casing for wells with minimal costs

Before you start drilling on your land plot, you should choose which material will be used for the casing. The efficiency of operation of the hydraulic structure and its service life depend on it. The most common casing for PVC or HDPE wells, but you can use other varieties, which will be discussed below.

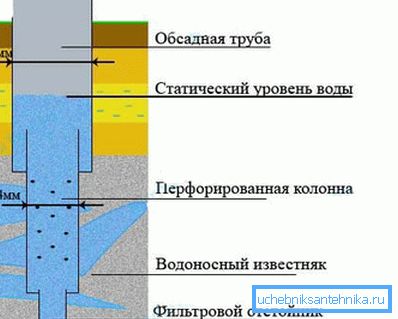

Well design features

This hydraulic structure is a fairly deep, but small in diameter, hole in the ground, which serves to provide water to a country house and a backyard.

Drilling a well allows:

- protect it from sewage;

- prevent the soil from shedding inside the hole;

- install and fix pumping equipment.

The casing is mounted directly during drilling or immediately after its completion.

Note! The installation of the casing is also necessary when drilling is done by hand with the help of a manual installation. This is especially true when the soil in the area is loose. Without pipes you can hardly complete the job successfully.

In addition to the material, it is important to choose the size of parts.

Casing diameters for wells vary according to the following scheme:

- 133 mm casing is installed to the limestone layer;

- 98 mm pipe is installed after passing limestone at a distance of no more than 10 meters;

- 114 mm parts are used, if necessary, as intermediate between 133 and 98 mm.

Remember that a submersible pump must be installed in a pipe of the smallest diameter.

In addition, the size of the casing depends on the type of well:

- Artesian - it is drilled to a considerable depth and gives a large amount of water. Products with a diameter of from 90 to 170 mm can be used for its casing.

- Sand - the depth of this hydraulic structure does not exceed 30 meters. Most often they use plastic casing for wells with sizes ranging from 125 to 170 mm.

Regardless of the material, casing components must meet the following requirements:

- have a long service life;

- withstand significant pressure of crumbling soil;

- do not change the chemical and physical composition of water.

Types of casing for wells

Steel

This material has been used for a long time and has excellent technical characteristics. Casing steel pipes for wells have good strength and perfectly withstand ground pressure. The disadvantage is the appearance of rust, which can pollute the water.

There are several varieties of these parts.

| View | Description |

| Galvanized | Their feature is the complete absence of corrosion. However, the rust particles that form in steel pipes are easily removed using filters, therefore galvanizing is not practical. In addition, these parts emit zinc oxide, which adversely affects human health. |

| Stainless | Also not subject to corrosion, but their price is very high, because such products are rarely used as casing parts for wells. |

| Enameled | Do not rust and are inexpensive. The disadvantage is easily damaged as a result of mechanical impact. If the enamel layer is broken, the casing quickly fails due to corrosion. |

Polyethylene

Casing PND for wells - with thread or smooth edges - has the following advantages:

- pipes withstand linear deformation without changing their technical characteristics;

- the material does not emit elements harmful to human health and has bacteriological safety;

- low pressure polyethylene is not destroyed due to the formation of ice in the well;

- casing plastic pipes for wells are easily replaced in case of damage;

- installation of casing does not require the use of specialized engineering equipment;

- no deposits are formed in the inner space of the pipe, because the diameter of the parts does not decrease during the entire life cycle;

- Low pressure polyethylene casing has a long service life.

Tip! When arranging a water supply system for individual use in a suburban area, it is recommended to use plastic casing pipes with threads for wells made of low-density polyethylene. They have an optimal price-quality ratio.

Polyvinyl chloride

The scope of application of PVC pipes is extremely wide. They are used to transport not only water, but also gas, sewage, and so on.

PVC casing for threaded wells is not very common, as they have many drawbacks:

- They become brittle at low air or water temperatures. In addition, fragments of cracked pipes can get into the water, and then into the water supply.

- Damaged parts are difficult to recycle.

- In the event of a fire, polyvinyl chloride releases substances into the atmosphere that could harm a person.

- The strength of PVC parts are much inferior to polyethylene.

Connection methods

The instructions for drilling operations include the use of the following types of connections:

- weld seam;

- trumpet;

- thread.

Regardless of the variety chosen, this node must meet the mandatory condition - to be absolutely tight.

The use of welding has several disadvantages:

- the quality, strength and tightness of the connection strongly depends on the qualifications of the worker;

- welding seam is subject to corrosion;

- during the execution of the connection, the entire casing is under increased loads and may be deformed.

The only plus is cheapness. Due to this factor, the welded joint is the most common in the construction of wells.

A bell is an even more unreliable connection. At the same time there is no possibility to control the quality and tightness of the joints. In addition, defects may already appear during operation due to shrinkage of the casing.

Threaded connection, although it is more expensive than others, is the most reliable and hermetic. But both steel and polymer pipes with thread are more expensive than counterparts with a smooth edge.

Conclusion

For well casing, it is advisable to use polyethylene pipes, which are connected using threaded couplings. This will allow you to operate the hydraulic connection for a long time and not be afraid of accidents. More information about drilling can be found in the video in this article.