How to choose polypropylene pipes for heating a residential

Recently, plastic has been actively used in dwelling heating systems, due to which it is possible to create completely tight and easily erected networks, especially if a choice of polypropylene pipes for heating was made. However, only the correct approach to the acquisition process will allow you to arrange reliable and efficient designs that can serve for many years.

About the advantages of products

Before considering the criteria for the selection of products made of polypropylene, it is desirable to become familiar with their general advantages in order to completely abandon the products of another type.

This material is a stable chemical compound that can be used in the device of various communication networks.

- Prolonged contact with water does not show signs of corrosion. on the inner surfaces of products.

- The price of plastic items is low, therefore, they can even be purchased by individual developers with low incomes.

- Installation technology does not imply complex actions., so, you can do the work yourself, saving a considerable amount.

- Used products have high flexibility, which makes installation operations much easier.

- Elements are connected by soldering or chemical bonding, This allows you to create systems with a high level of sealing.

- The service life of pipes with proper operation is very long and can reach 50 years.

Addition! Products made on the basis of polypropylene, can withstand abrasive effects, as well as dynamic and static loads. The material absorbs sounds and poorly conveys vibration.

Main selection criteria

Immediately before purchasing products, it is necessary to study the basic parameters that need to be considered for the heating system to function as long as possible. If not quite suitable elements are bought, the operational period of the entire network will noticeably decrease.

Feedstock

Depending on the modification method, there are several types of material, but not all of them are suitable for heating and hot water supply, which is associated with different thermal resistance. Products based on static polypropylene copolymer (PPR) are most often used to construct a housing heating system. As for the other varieties of pipes, they are most relevant when laying water pipes, ventilation ducts and other communication networks.

Withstand pressure

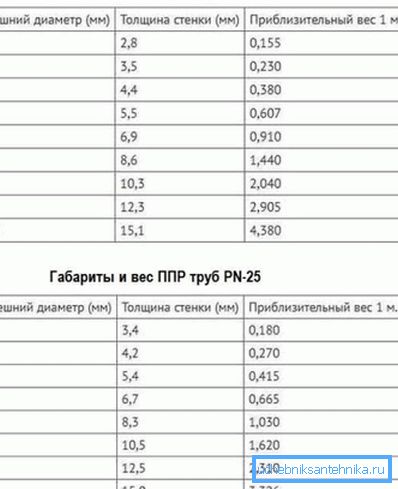

There is a classification of products directly on the ability to withstand a certain level of pressure. You can get acquainted with various types of products, if you look at the table. It presents the main parameters that play an important role in the selection.

| Category | Purpose | Pressure in MPa |

| PN10 | Cold water with temperatures up to 45 degrees. | 1.0 |

| PN20 | Hot water with temperatures up to 80 degrees. | 2.0 |

| PN25 | The device of heating systems with the temperature of the coolant up to 95 degrees. | 2.5 |

Conclusion! On the basis of the table above, it can be concluded that the formation of a heating network in a residential building will require elements labeled PN25 with a reinforcing layer.

Bandwidth

This parameter is relevant for all types of pipes, but it should be given special attention, that is, it is necessary to calculate the cross section correctly. In most cases, to create a heating system, items with a diameter of 20-40 mm are purchased.

However, in fact, many factors must be taken into account in the calculations: temperature and velocity of the coolant, pressure and length of the pipeline.

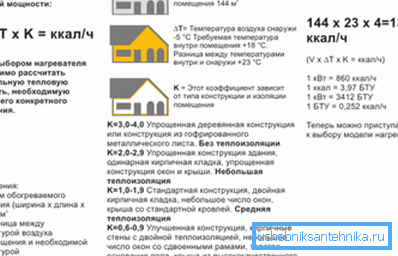

Before determining the diameter of the component parts, it is necessary to calculate the thermal power that will be required to heat the premises during the winter period. Calculations can be made by the following formula: Qt = V *? T * K / 860.

The meaning of the symbols is presented below:

- Qt is the required heat output in kW / h.

- V is the volume of the internal space to be heated.

- ?t is the temperature difference between the internal environment and the street.

- K - heat loss coefficient: up to 0.9 - a high degree of thermal insulation, from 1 to 1.9 - an average level of insulation, from 2 to 2.9 - weak protection.

- Dividing by the last number means conversion to kW / h.

After calculating the heat output, you can determine the required pipe diameter without any particular difficulties. In another formula, you will have to substitute the load on the system directly in kilowatts and other parameters.

It turns out: D = 0.86 * Q /? T / V.

- D is the diameter of the element in centimeters.

- ?t is the temperature difference between the inlet and outlet sections.

- Q - thermal power, which was determined by the previous formula.

- V is the velocity of the fluid in the pipeline.

Note! Thanks to the above two formulas, you can easily choose the diameter of polypropylene pipes. The end result should be rounded up in order not to reduce the throughput.

Reinforcement options

In order to improve the load-carrying capacity of the product and, to some extent, reduce the linear expansion coefficient when changing the temperature, a reinforcing layer is introduced into the plastic mass. It is usually formed using one of two materials.

Aluminium foil

The reinforcing layer is environmentally friendly, as it is based on a light metal. Aluminum foil is bonded to the rest of the structure with a special adhesive. The thickness of the reinforcing streaks is only 0.1-0.5 millimeters.

Fiberglass layer

The material is a fiber derived from glass. With it, it is possible to obtain flexible canvases. Continuous fiberglass is produced by pulling the liquid mass through special dies, having from 200 to 4000 holes. The technological process usually takes place in one or two stages.

In the manufacture of pipes made of polypropylene, the reinforcing layer is usually joined by welding with the other two, forming a cohesive and solid construction. In heating systems products with a layer of fiberglass can be successfully used, like analogs with aluminum foil.

Final part

The information provided should help to figure out which polypropylene pipes are better for heating and which ones should not be used. Also, this manual contains useful information on how to calculate the diameter of the elements for a heating system of a dwelling house using special formulas. As a visual aid it is recommended to use the attached video.