How to connect asbestos-cement pipes

Asbestos cement pipes do not lose their popularity and relevance and are used in many areas of activity. This is largely due to the good performance characteristics of the material. However, among the qualities inherent in such products, we can mention certain difficulties when working with them. For example, it is necessary to consider in more detail how to connect asbestos-cement pipes, as there may be difficulties in performing the work.

Material description

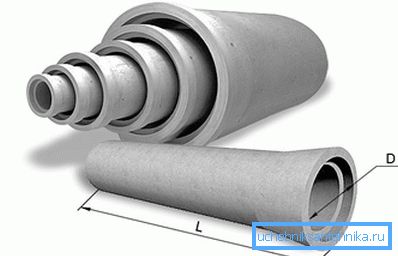

To begin with, it is necessary to say a few words about what are asbestos-cement pipes and designate the basic properties of this material, since the nuances of the work will largely depend on this.

Asbotsementny pipes are the material used when carrying out water or sewer works. Can also be used for the manufacture of chimneys. Such pipes are made of a mixture of cement, asbestos and water. The result is a material with the following characteristic properties:

- Chemical neutrality

- Durable use.

- Corrosion Resistance.

- Resistance to high temperatures.

- Availability of material.

However, at the same time, asbestos-cement pipes have some difficulties in their work, mainly due to the large weight of the pipes and the tendency of the material to crack under mechanical stress.

It is important to note that asbestos-cement pipes that are used when laying water or sewer communications can be divided into two types:

- Non-pressure pipes.

- Pressure pipes.

As the name implies, the pipes of each type are designed either for work under pressure or without it. Depending on the type of pipes will differ and the methods of their connection with each other.

Connection methods

Basically, special couplings are used to connect water asbestos-cement pipes. These connecting elements are segments of the same asbestos-cement pipe, the inner diameter of which is slightly larger than the outer diameter of the elements being joined. In addition, to ensure the tightness of the connection and the ability to cope with the pressure loads that occur during operation, special sealing rubber rings are provided inside the couplings. On the elements to be joined, in turn, there are special grooves into which these rings fit in at the articulation. The resulting compound has sufficient strength and tightness.

Tip! When choosing a coupling it is necessary to pay special attention to the quality of workmanship. On the surface of the connecting element there should be no visible defects such as cracks, chips, shells or noticeable irregularities. It is also worth paying attention to the quality of the rubber seals.

Another option for connecting the pipes to each other is a socket. The idea is that the pipes are equipped on the one hand with a socket for the connection, and on the other, they have a special undercut corresponding to the diameter of the socket. Pipes are simply inserted one into the other. Such connections can be used for non-pressure use of pipes.

The process of laying and joining

Regarding the process of laying and joining asbestos-cement pipes, it is worth saying that it is best to carry out the work in stages.

Training

To ensure a successful result of the work, you should pay attention to the quality of the preparatory work. Here we are talking about the fact that the trench should have a uniform slope, and the bottom should be as smooth as possible. It is necessary to ensure that the laid piece of pipe lay on the bottom of the trench with its entire surface. This is necessary because the fragility of asbestos cement can lead to cracks under the influence of the weight of the soil, if there are distortions in laying. It is important to know that direct transportation and stowage must be carried out immediately before work. All this is due to the properties of the material.

Piling and joining

After preparation, you can begin to work on laying and connecting pipes. Here it is important to understand that it is unlikely that you will be able to perform all the work yourself, and therefore you need to attend to the involvement of several assistants. In addition, if the diameter of the pipes, and accordingly the weight of the products, is significant, then it will be necessary to use specialized equipment.

- First, the two parts of the pipe are laid at some distance from each other.

- Further, a coupling is put on one of the ends of the pipe. For convenience, it is recommended to lubricate the rubber o-rings with grease or a similar compound.

- Next, the second pipe section is inserted and the coupling sleeve slides over it. A special screw jack is used to move the coupling. It is important to monitor the alignment of the pipes, as the distortions will complicate the work.

As one of the options for connecting asbestos-cement pipes, use of special polyethylene couplings can be mentioned. This option is used, for example, when laying communication lines. At the same time, the main stages of work are similar, but before work with a polyethylene coupling, it must be preheated in order to acquire greater elasticity.

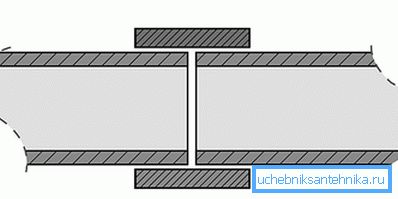

For the sake of completeness, it is worth noting cases when it is necessary to connect pipe sections. This may be, for example, in the repair of sewage. To connect the pipes, it is better to use the “Zhibo” type couplings. The essence of the work is as follows:

- A special flange fitted with a rubber seal is put on one end of the pipe to be connected.

- The same procedure is carried out with another connected element.

- The flanges are centered and bolted together.

In conclusion, we can add that there are several ways to connect asbestos-cement pipes, it is necessary to choose a specific option, based on the circumstances. Whichever option is chosen, the work must be carried out carefully and responsibly.

Video

This video describes the varieties and applications of asbestos-cement (asbestos-cement) pipes: