How to connect cast iron pipes with plastic

Today, the apartments still serve a lot of old cast-iron sewage pipes, which have already outlived their useful life, so there is an urgent need to replace them with plastic ones. It is often unknown how to connect cast iron pipes with plastic, because they are made of completely different materials. There are a variety of ways to dock pipes from dissimilar materials, which will be discussed in this article.

Training

Before you start the installation work on the connection of the cast-iron pipe element with a plastic pipe or nozzle, you need to draw or “sketch” the layout of the communication system. Based on the size of tubular parts and nodal joints, it is necessary to calculate the footage and the amount of material needed. Risers are O110 mm, and pipes for wiring (depending on what device they move)? O110 mm and O50 mm. The diameters of the elements to be joined must be identical. Shaped parts in the form of taps and transitions, tees and flanges, as well as other adjacent parts must fit the appropriate pipes.

To perform the work will need the following tools and connecting parts:

- pipe products of the required diameter;

- parts for connections;

- rubber adapters of the required size;

- wooden or rubber hammer;

- Bulgarian or hacksaw.

Further work on the installation of the pipeline occur as follows:

- Cut inoperable section of the pipeline grinder (hacksaw). To prevent anything from falling into the pipe, cover it for the duration of the work.

- Procurement of necessary materials and fittings is done. Pipes of a certain length are cut. If dismantling the pipe reached the socket, you need to clean it of dirt to conduct the connection.

Tip! When working with cast iron you need to remember the fragility of this material.

Connection with rubber gasket

If the replaceable cast iron pipe is easily removed and the socket to be used is in good condition, a simple connection method using a rubber insert is used. It is plentifully smeared with sealant, and then inserted into a cast iron pipe. Now the sealant is applied to the inside of the rubber liner, and the plastic pipe is inserted as deep as possible into the cast-iron one. The depth of entry is from 30 to 80 mm. This method of docking is carried out quickly, after which the operation of the sewer network can be continued immediately.

Tip! From the practice of applying such a compound, it is known that it is able to work without repair for about 9 years.

Due to the fact that the outlet pipe from the toilet bowl has O100 mm, from the washbasin and sink O50 mm, from other devices is either 100 or 50 mm, it is not surprising that the sewer system includes oblique tees or crosspieces of the same size. In both cases, the pipe is fixed according to a known pattern. Need to:

- remove dirt and rust from the cuff;

- apply a sealant on the outer side of the socket with a rubber transition;

- insert an adapter made of rubber material into the cast-iron cuff;

- put a new plastic sewer pipe into the socket.

If you have to deal with a pipe in which there is no cuff due to the fact that it was cut off as needed, you need to use an adapter made of plastic. Then proceed as follows:

- a cast iron pipe that does not have a socket is re-cut with a hacksaw in order to level the plane of the pipe end;

- on the trimmed and leveled end tighten the rubber adapter;

- lubricate the stain of “shod” tubular cast iron product with a sealant;

- on the pipe tensioned with greased sealant socket adapter made of plastic.

Tip! Transitions and sockets should be identical in size to pipes. Regardless of the diameters of plastic and cast iron pipe products docking is performed using the same technology.

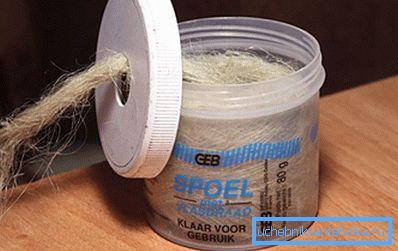

Towing

This method has been tested over the years when working on the connection of cast iron pipes. Thus, it is possible to connect a plastic pipe with cast iron, but now this method is not relevant, due to the complexity of execution, as well as the availability of simpler methods of pipe joining. Consider it as an emergency option when there is no opportunity to purchase the necessary parts. According to this method, the work is performed in the following order:

- on a plastic pipe product in the area of the connection, a linen underwinding is wound in several turns;

- tow with the help of the back of a knife or a large screwdriver compacted into the existing gap between the pipes;

- the cast-iron pipe at the point of transition into several passes is trudged with polymer-cement liquid consisting of PVA glue, cement and water;

- after the work done sewer system can not be used for at least a day.

Tip! Due to the fragility of plastic pipes, work should be done very carefully, avoiding the use of great effort.

When there were no silicone sealants on the market, this method was widely popular. Nowadays, it can be used, for example, when joining cast-iron and plastic pipes under washroom sanitary products. A few years after such a connection, the pipes, if they leak, are not in this place. If the connection made with the help of the flax made is correctly made, then it will be sufficiently durable and reliable.

Sanitary silicone

If small gaps (around a few millimeters) occur when connecting plastic and cast iron pipe products, silicone is quite effective against leaking. Considerable attention should be paid to the tightness of the connection in the lower section. To do this work you need:

- Before docking the joint should be well dried with a building dryer.

- A special gun in the existing gap between the pipes pour silicone (the deeper the better). The large depth of penetration of silicone will increase the reliability of fastening

- Wait about 5 hours for the construction substance to cure completely, remembering that the silicone in large gaps will dry longer.

Tip! It is not recommended to use sanitary equipment until the silicone is completely dry.

Combining methods

All the above methods can be combined with each other. This will only increase the reliability of the joint between pipes made of different materials. Connection of sewer pig-iron pipes with plastic will turn out even better:

- If there is a large gap at the junction of pipe products, rubber liners and flax underwrap can be used together. When connecting the corrugations at the interface, apply towing followed by the application of building silicone. In this case, the sealant passes through the right places of the cross and the rubber seal.

- When sealing, polymer-cement liquid is sometimes replaced with a sealant, which contains silicone.

One should not forget that iron and plastic at different (especially high) temperatures have a different coefficient of expansion. This should be considered if very hot water flows through the pipes.

All methods of connecting pig-iron and plastic pipes can also be used for joining pipe products made of plastic only.

Video

From this video, you can learn how to correctly cast a cast iron pipe: