How to connect metal pipes

At present, the main part of the construction market is occupied by metal-plastic pipes. Their popularity is due to sufficient strength, flexibility, resistance to temperatures up to 110 ° C, corrosion resistance and installation speed.

In addition, they are able at the expense of the reinforced hull and smooth inner surface to pass large streams of water with minimal loss of efficiency. The metal-plastic pipe is a multi-layer structure consisting inside of a polyethylene layer, covered with aluminum film from above, as well as an outer plastic layer. The layers are glued together with a special glue.

Due to the resistance to rust, no deposits are formed inside the pipe, so the pipes can be used for sewage, heating, underfloor heating and water supply. On highways they are not used due to the fact that they do not withstand high pressures and temperatures. Their service life is up to 35 years.

If we compare such pipes with pipes from other materials, then they have no equal in cost and quality of material, if we take the limits of permissible intervals at which operation takes place. Most people do not know how to connect these materials, so we will tell you how to connect metal-plastic pipes.

Ways of joints of pipes made of metal

Metal-plastic pipes are connected using compression and press fittings.

Compression Fittings

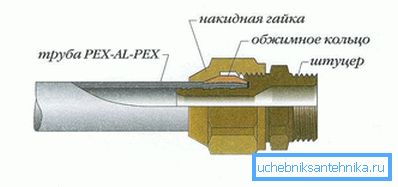

Compression fittings are threaded. A flare nut is screwed on one side, and the tube is fastened inside with a compression ring.

When tightening the cap nut with a wrench, the pipe is pressed against the press sleeve and pressed into the nozzle. This creates a reliable connection. The material for the fitting is brass. Fittings are marked on the outer diameter and on the type of thread.

Tip! The advantage of this connection is the ability to connect pipes without the use of special tools and equipment.

In addition, it is possible to dismantle the connection without destroying the fitting, but in practice this is not always possible due to breakage of the compression ring. Despite this connection remains reliable and tight.

Installation of compression fittings at the connection of metal-plastic pipes does not cause any problems, since they can be connected both in the collector and in the form of a tie-in. Connection technology consists of the following steps:

- The pipes requiring connections should be leveled at a distance of not less than 100 mm, should be cleaned of dirt, and the internal chamfer should be removed by approximately 1 mm, depending on the wall thickness.

- A pipe nut and a compression ring are put on the pipe.

- Tighten the nut until the pipe runs into the edge of the nozzle. In this case, the nut should not go through the thread with effort. If it is necessary to make an effort at the initial stage, this means that the nut goes wrong along the thread. In order not to twist the thread, you need to remove the nut and put it on again.

- With the wrenches, the nut is finally pulled down by 1-2 turns so that there are still two turns of the thread. At the same time, it is not necessary to exert excessive efforts, since the necessary tightness has been achieved.

Tip! If necessary, laying pipes in unheated rooms in order to prevent condensate from settling on them stretches polyethylene corrugated tubes that are wrapped with tape.

Slide fittings

Press or nadvizhny fittings are a fitting with a threaded connection on the one hand, and on the other - crimp sleeve, worn on the sealing ring with a dielectric gasket.

Tip! Such a connection is sealed, so it can be used when installing internal pipes, but it is not collapsible.

In addition, a small amount of reinforcement is used. The connection is carried out in this way:

- The required pipe length is cut off.

- The joined part is processed by a calibrator, which cuts the internal chamfer and corrects the rounded shape of the pipe, broken due to cutting.

- The pipe is tightened on the fitting with a gasket sealing rings that prevent rust.

- The coupling is crimped using special clamping pliers.

- As a result, on the clutch protruding protruding rings are formed, and the metal gets an arched bend due to the deformation.

Connection with metal pipes

These types of connections are most often encountered when connecting old pipes with new ones during repair or scheduled replacement. Directly they can not be combined, because the materials are different and have different coefficients of expansion and strength. Therefore, it is necessary to apply different types of elements that will allow to connect metal-plastic pipes with metal ones.

There are several types of such compounds:

- Threaded. It is the most convenient because it is collapsible. Applicable in pipelines where control of the condition of the connection is required.

- Coupling. It is designed for different pipe diameters and is also collapsible. It is similar to press fittings, except that on one side there is a compression nut for attaching a pipe made of metal-plastic, and on the other side there is a threaded or flange fastening.

Connection with polypropylene and PVC pipes

To connect a metal-plastic pipe with a polypropylene pipe, it is necessary to use the fitting compression joints described above, as well as connections of a similar type for the second pipe material. A sealing nut is put on the polypropylene pipe, then a ring and a special pipe insert that performs the function of strengthening the pipe. It prevents its deformation and, accordingly, the loss of tightness of the connection when tightening the nut.

PVC pipes are connected to metal-plastic with a flange connection, and the pipe with a flange is connected by an adhesive method. This allows you to make the connection reliable and capable of withstanding loads up to 10 Atm. The technology of adhesive bonding is as follows:

- The end of the pipe is cut and cleaned, which is then treated with a degreasing compound.

- The face is removed chamfer, which allows for a reliable connection.

- Apply a thin and uniform layer of glue to the outside of the pipe.

- If necessary, glue should be applied to the flange surface if the diameters differ by a few mm.

- The pipe is inserted into the fitting and rotated a quarter turn to evenly distribute the adhesive layer.

- The fitting and pipe are fixed for a few minutes until the glue sets.

- Remnants of glue that come out need to be removed.

- After 10–15 minutes, the connection is ready for operation.

The joining of metal-plastic pipes with their own hands should not be a particular problem, because today there are a huge number of different types of connections not only for homogeneous materials, but also for very different in properties and conditions of operation. In addition, most of them do not require the use of special tools, which greatly expands the possibilities of their installation.