How to connect pipe mon. with polypropylene

Often there are cases when making a pipeline, you have to face the problem of connecting pipes from different materials. In this article we will look at how to connect the HDPE pipe with a polypropylene pipe.

Types of polypropylene pipe connection

For connecting polypropylene pipes with other types of pipes there are special fittings with threads. One side of the fitting is welded to the polypropylene pipe, and the other side, with the thread, is connected to the same diameter with a thread on the other pipe. The thread on the fitting can be internal or external. There are also combined couplings. We will consider them later.

Another type of polypropylene pipe connection is based on a flange connection. This type of connection is used in large pipes. To fasten the flange to the polypropylene pipe, a sleeve is welded onto which the flange is then fitted. Another mounting option is carried out by cap flanges. Their device resembles a compression coupling. The flange connection is attached to the edges of the pipe of the same diameter, and tightened with flare nuts.

Types of connections for HDPE pipes

Pipe PND has approximately the same devices for connection. The most common - collet connection. To connect the pipes, a coupling is used, in which there is a collet on one side and a thread on the other. To fasten the coupling, the clamping nut is unscrewed and put on the HDPE pipe. The collet is inserted into the pipe, the clamping nut is put on and tightly tightened.

Tip! The clamping nut must not be clamped very tightly, otherwise it may burst or the collet will crush the edge of the pipe.

After the collet is connected to the other end of the threaded collar, another pipe with a thread of the same diameter can be screwed on.

The flange connection of the HDPE pipe is made similarly to the connection described above. On the edge of the HDPE pipe is welded sleeve on which the flange is mounted. And the same device with a cap flange, where the connection is installed on the edges of the pipes and pressed with cap nuts.

Connection of two pipes

Using the above-described devices for pipes, you can easily connect the HDPE pipe with polypropylene.

- In the first case, you attach a threaded collet to the HDPE pipe and a combined threaded coupling to the propylene pipe. On the thread winding FUM tape for sealing and twisting them.

- In the second case, you connect two pipes with flanges. Insert the rubber gasket between the flanges for sealing and tighten them with bolts.

Combined couplings

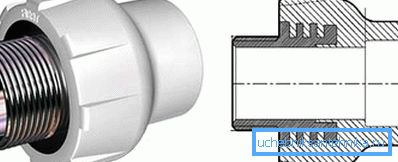

If with a collet connection for HDPE pipe everything is clear, then the combined couplings (fittings) for polypropylene pipes are various. Let's take a quick look at them:

- A female threaded coupling serves to connect the pipeline with another type of pipe or instruments with external threads. It consists of a polypropylene billet with a metal coupling pressed inward, on which a thread is cut inside.

- An external thread coupling performs the same functions as discussed above. It differs only in that a metal sleeve with an external thread is pressed into the polypropylene billet.

- The turnkey female thread coupling consists of a polypropylene billet into which a metal sleeve is pressed, protruding metal edges over the edge of the polypropylene. Faces are designed under the open-end wrench. Inside the face is carved. It is convenient to twist such a sleeve with a key for another thread. Also there are models of couplings with turnkey faces.

- A turnkey male coupling is the same as the coupling described in paragraph 3, but has an external thread.

- Split coupling with internal thread consists of two metal parts under the open-end wrench. Moreover, one metal part is connected with a polypropylene billet. Such couplings are installed in places where it is necessary to disconnect the pipeline or remove the devices. Another name for this clutch is American. Spun it with two keys.

- Detachable coupling with external thread is similar to the previous type of American. The only difference is in the external thread instead of the internal one.

- The coupling with a cap nut consists of a polypropylene billet into which a fitting with a cap nut is pressed. It is installed in the same way as an American: in the places of the necessary connector of the pipeline.

With these combined couplings soldered to a polypropylene pipe, it is easy to connect to the HDPE pipe, which has a collet with a similar thread.

Soldering PP Fittings

Before connecting the two pipes with fittings, they must be fixed on the pipe. Mounting collet on the HDPE pipe, we discussed above. Now consider the connection of a polypropylene pipe with a fitting.

Polypropylene pipe fittings are connected by soldering with a special soldering iron. A soldering iron with nozzles is installed on the stand and heated to 260aboutC. The edge of the pipe is cleaned of dirt, chamfered and degreased along with the inside of the coupling. Pipe and fitting at the same time put on heated nozzles. After heating, the pipe is inserted into the fitting evenly without turning and allowed to cool. This completes the soldering process.

After reading this article, you can easily connect a polypropylene pipe with a HDPE pipe. Here are all the possible options for the correct connection. There are enthusiasts who assert in construction forums that these two pipes can be soldered with a coupling at different temperatures. But the thing is that polypropylene and HDPE are made of different materials, they have different melting points, so this seam may burst or even melt. If you decide to save and experiment, then do it at your own peril and risk.

Video

One example is how to replace a section of an iron pipe with a polypropylene one. The same principle can be used to connect plastic pipes of various materials:

A photo

In these photos you can see how you can still connect plastic pipes: