How to connect polypropylene pipes in efficient and modern

Modern methods make it possible with the help of PP elements to pull durable and reliable engineering networks that are not subject to corrosion. In this case, it is important to know how polypropylene pipes are connected.

They can be mounted using threaded or welded fittings.

Pairing methods

High-quality pairing of PP pipes is impossible without taking into account their wall thickness.

Below are the thin-walled products that are connected by threaded fittings.

- Pipes of brand PN-10 for cold water supply (operating temperature + 20 °) or “warm floor” systems (up to + 45 °).

- Analogues PN-16 used for cold water supply with increased pressure or in heating systems with low pressure.

Welding is the best option in the following cases.

- If you mate with their own hands universal pipes brand PN-20. These products are able to withstand the working environment temperature of + 80 °.

- When aluminum foil reinforced pipes are joined PN-25. This product is designed for hot water and heating systems. It maintains the temperature of water or coolant in + 95 °.

Note! Polypropylene pipes are easy to connect, so popular. It is possible to connect them, even without having special sanitary preparation.

Docking without thread

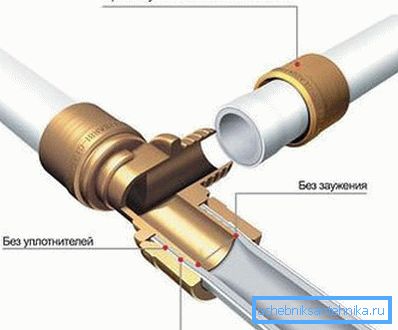

Plastic pipes can be connected without soldering using press fittings, crimp counterparts, or the latest Belgian push fittings, which are fixed themselves.

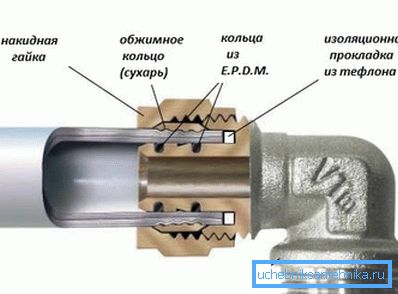

- Crimping elements require only two wrenches. Before connecting the HDPE pipe with polypropylene pipe, it should be noted that press fittings are more reliable. They create a guaranteed tight connection. However, to work with them you need a special tool.

- Push fitting only needs a calibrator and cutter.. They are made of PVDF, a material that is environmentally friendly and durable. To seal the elements, EPDM rings are used, which are the most reliable. The price of such fittings is quite high, but they are worth it.

Threaded connections

First about how to connect pipes made of polypropylene using detachable elements.

It is impossible to cut threads on your own PP pipes. Therefore, you will need threaded fittings for splicing. To ensure the tightness of the joints, plumbing Teflon tape (fum-tape) and seals will also be needed.

Types of threaded fittings

- Couplings with the same thread at both ends.

- 90 ° and 45 ° squares with cap nut.

- Triple squares and tees for connecting pipes of the same diameter. They may have an external or external thread.

- Crosses

- Stubs

- Saddles for branching network.

- The combined couplings with an external and female thread, and also cap nuts.

- Adapters with an external carving like DG.

- Combined squares at 90 ° with external and external threads, as well as cap nut.

- Combined tees having the same structure.

- Squares for fixing plumbing fixtures.

- Passable water sockets.

- Ball valves, angled (with "American") or straight.

The instruction says that it is very easy to dock pipes with these elements. You only need to pre-wrap the fum-tape, and then screw the fitting on the pipe.

Docking elements of various materials

It is a little about how to connect a metal pipe with polypropylene.

- For this you need special adapter fittings. One end of them is designed for soldering with a plastic element, and the other has a thread for connection with a metal counterpart.

- Used and collapsible type of connection. This so-called “American” is a fitting with a metal insert and a cap nut or a PP fitting and a cap nut.

Note! The best option is to use elements with nickel-plated brass inserts for transitional interfaces with metal pipes. Fittings should be screwed with a long wrench. On sanitary devices, plastic-threaded transitions should not be used.

Welded method

Welded mating all-in-one. During the fusion of the sides of two elements, their macromolecules mutually penetrate into the parts and unite with them. That is, the process of diffusion.

Therefore, such welding is called diffusion welding.

- For products with a cross section of less than 63 mm, socket type welding is used.

- For analogs with a diameter greater than 63 mm, a butt type of welding is used.

The process of socket welding

Before you connect polyethylene pipes or analogs of PP, you need to prepare the tools and materials.

- Soldering iron (iron) for plastic products, a hacksaw for metal or a special cutter, tape measure and marker. If the elements are reinforced, then a shaver will be needed - a device for stripping aluminum foil.

- Of course, the pipes themselves will be needed and, as necessary, different types of fittings.

The welding machine includes a heating element and a set of nozzles for pipes of different sections - from 16 millimeters to 63. When the soldering iron turns on, the indicator starts to work. As soon as it changes color from green to red, the nozzle is heated to the required temperature of +260 degrees. It happens in 10/15 minutes.

Note! All work is best done indoors. In any case, with a negative ambient temperature, the pipeline cannot be welded.

Briefly, the process looks like this.

- Put on the pipe mark. Do not forget about the depth of the socket and add 2 mm to it.

- Cut the necessary pieces of pipes. Do this strictly at right angles.

- Install the connecting sides of the elements on the heated nozzle of the welding machine.

- Wait for the time to heat the pipe and fitting.

- Take out the items.

- Connect the parts and firmly press them together.

Large diameter pipe connection

Butt welding is used to connect plastic pipes having a large diameter and wall thickness (4 mm or more): sewer or main water pipes.

For this method of welding fittings in most cases are not needed.

- First, weld sides are faceted, to their full parallelism.

- Pipes are inserted into the welding machine.

- Further, they are connected, while the accuracy of the work is regulated by the centering device.

- During the work, do not forget to ventilate the room, as the plastic smokes, emits carbon dioxide and water vapor.

Below is a table of welding characteristics.

| Section of pipes, mm Depth of welding, mm Heating, sec. Welding, sec. Cooling, min. |

| 20 14 5 4 3 |

| 25 16 7 4 3 |

| 32 20 8 4 4 |

| 40 21 12 6 4 |

| 50 22.5 18 6 5 |

| 63 24 24 6 6 |

| 75 28.5 30 8 8 |

| 90 33 40 8 10 |

| 110 39 50 10 10 |

Conclusion

Having figured out how to properly connect the PP pipe, you can very quickly assemble a high-quality plumbing, heating or sewage system at home.

The video in this article will tell you more about its topic.