How to connect polypropylene pipes

Each building material has its own life, at the end of which it is necessary to replace the damaged products. Pipes are no exception. Modern polypropylene pipes are so easy to install that they allow you to make the replacement of the entire heating system or water supply without much effort. To learn how to connect polypropylene pipes, it is enough to read the article.

Several major advantages of such pipes:

- Strength. They are able to withstand pressure surges in the system and high temperature without changing their characteristics.

- Durability.

- Resistance to corrosion.

- Ease of installation. To install the pipes, it is enough to heat them with a special device and connect them with fittings. Connection of polypropylene pipe with metal is also carried out using fittings.

Instruments

Simplicity of installation is the first and most important advantage of polypropylene pipes, however, additional materials and tools will be required.

- polypropylene pipes,

- pencil,

- pipe fixing clips,

- roulette,

- couplings,

- Merilon insulation,

- corners. We will need products of two types: under 45 and 90 degrees,

- Mr-eared mouse It is used to fix the mixer,

- MRI and MPH metal thread outputs,

- soldering iron

- scissors for plastic products.

Installation

How to make the installation system using pipes made of polypropylene, so that the result was durable, we consider below. If you still have doubts about your skills, or you do not dare to replace the products yourself, then forget about it forever. The fact is that even improper adhesion of such pipes can be corrected by couplings.

Tip! When choosing polypropylene products, refer to the diameter of old pipes, which will help to simplify the installation of the entire structure.

Diffusion welding

Polypropylene products can be connected in several ways, but the most popular is diffusion welding. For reliable fastening of products, fittings are used here: couplings, angles and adapters.

Polypropylene pipes in the cold water supply system are guaranteed to last up to 50 years. About a quarter of a century, they will be able to serve in the arrangement of hot water. Do not forget that the service life of these products depends on the pressure and temperature of water in the structure.

The pipeline of polypropylene has a large margin of safety, allowing it to withstand all changes in the system. Thus, high pressure and low temperature indicators will not affect the service life of products. The same effect on polypropylene pipes will have a low pressure with high temperature. However, high pressure and temperature, simultaneously recorded in the system, will reduce the service life of products by 5-7 years. There are no excessive loads in the household piping that can damage the pipes, so do not worry.

Tip! Polypropylene pipes, for fastening of which permanent connections are used, can not be disassembled later.

Categories of polypropylene pipes

All polypropylene pipes are divided into:

- PN 25. The pipe withstands 2.5 MPa. Used in heating and hot water systems.

- PN 20. Universal pipe capable of withstanding 2 MPa. It can be used for cold and hot water, provided that the temperature of the system is not more than 80? C. Polypropylene pipe in this category belongs to the products of high strength, since its inner part is reinforced with foil.

- PN 16. Pipe for low pressure heating systems and cold water supply.

- PN 10. The thin-walled pipe enduring pressure of 1 MPa. It is widely used in the construction of a heated floor (but at a temperature not higher than 45? C) and cold water supply (up to +20? C).

A video with vivid examples of the use of pipes of a certain category will help determine such a difficult choice:

Types of fittings

Two pipes made of different materials (metal and polypropylene) can be connected with special fittings. They also help in connecting sanitary equipment with steel reinforcement. Inserts on the fittings are needed for reliable fastening products and they are brass or chrome. How to use them correctly and where it is better, we will not touch on now, but consider only their varieties:

- cross,

- combined tees,

- couplings,

- corner ball valves and straight,

- stub

- squares at 45 and 90 degrees,

- square (triple or to connect identical pipes),

- water outlet,

- transition. It has an external thread or DG type plastic.

- welded saddle

- combined couplings

- combined squares for pipes,

- combined squares for devices.

Progress on pipe joining

Fastening products made of polypropylene is a simple process, but requires care and accuracy. To do everything right, you need to read the instructions that come with the soldering iron. It is better to carry out all the work on the soldering of pipes in stages.

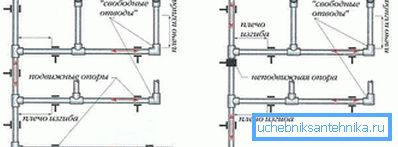

At first we make the scheme! New plumbing begins with the marking of taps, filters, turns and other details. After drawing up a detailed scheme, you can proceed to the partial assembly of the pipeline. Part of the parts can be connected without soldering, using glue, but the other requires a special tool. To make the soldering process easy, hold the pipes horizontally.

To connect the pipes located vertically, you need an assistant. The second person should only fix the product in its place, and you will solder, after removing the soldering iron from the stand. The last stage is the assembly of the resulting parts into a single structure. Here you also need an assistant.

For the connection of polypropylene products with a diameter of more than 63 cm, butt welding is used. This method of fastening products is considered the most reliable, and for its implementation does not require additional details.

Fuzioterm device

Cold polypropylene pipes are wound and tightened in place, after which the joints are processed by the Fuzioterm apparatus. If welding of two ends of products is required, they must be inserted into a special hole in the apparatus. That soldering apparatus is turned on, it is allowed to warm up to 260 degrees, the pipes are inserted into a special hole, they withstand the set time, they are removed and connected.

Tip! The heating temperature must be checked before welding.

Bell soldering

Polypropylene pipes with a diameter of less than 40 mm can be connected with a manual welding machine. Connection of a polypropylene pipe with a metal part cannot be carried out in this way. This technique has a centering device and several special nozzles. It is possible to turn on such a device only after its reliable fixation and installation of nozzles.

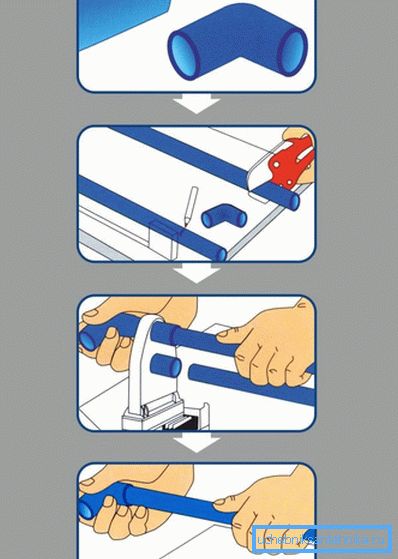

The procedure for bell-shaped soldering

- Cut off part of the polypropylene pipe can be special scissors. The reinforced product will need to be processed by stripping the reinforcing layer at the cut point.

- Wearing gloves, heat the apparatus and begin soldering.

- Welding should be carried out very quickly to avoid deformation of the joints.

Video

We invite you to see how the pipes are made of polypropylene: