How to connect sewer pipes

When laying sewer pipes, special attention should be paid to their connections to ensure long-term operation without breakdowns. Since sewage pipes are in most cases self-flowing, the main requirement for the connections is tightness, which is ensured by the use of various sealing materials. Due to the fact that through the pipes there can be heterogeneous waste with solid inclusions of various fractions, all the joints and turns should be smooth, one should not create additional obstacles inside. If it is impossible for any reason to organize a pipeline with independent flow of effluent, forced pumping is used. A high pressure can be created in the system depending on the pump power and the diameter of the pipe, therefore it is necessary to monitor the strength of the connections. In this article we will look at how to connect sewer pipes.

Typically, for the design and installation of sewage attract experts who fully calculate the load on the entire system and produce the full range of work. As for private households, you can do the connection sewer pipes with their own hands.

Types of sewer pipes and connections

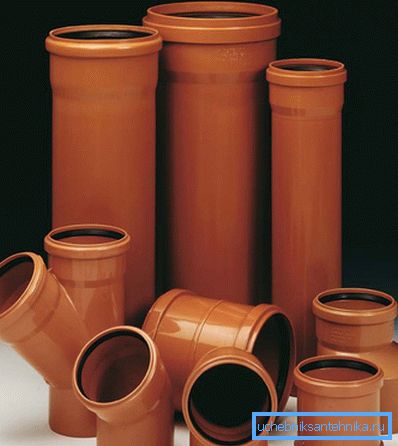

Currently, there is a wide selection of pipes for sewage and various types of connections:

Sewer plastic pipes have become the most common nowadays, since they are not affected by corrosion, they are light enough and have a maximum service life of up to 30 years. They are connected by gluing, soldering (plastic welding) and threaded connections.

Cast iron pipes are an alternative to steel pipes, because they have high corrosion resistance and withstand the effects of some corrosive environments. But this material is fragile due to its high carbon content and does not withstand hammer blows, which can cause some difficulties during pressing. It connects welded connections and bell-shaped.

Pipe preparation for connection

Before connecting the sewer pipes, you need to select the appropriate type of connection, and then make measurements, mark up their surfaces intended for the connection, and clean them from dust and dirt. At the same time using an abrasive tool is not recommended. The surface intended for welding must be cleaned and degreased. Threaded connections are cleaned of rust before applying a layer of sealant.

Welded pipe joints

To connect butt-weld pipes, they are clamped in special clamps, cleaned of the oxide layer, degreased and, if necessary, preheated, depending on the pipe material, and then welded.

Tip! Deviations in diameter and thickness should not exceed 0.5 mm, as this can lead to permanent blockages in the pipeline.

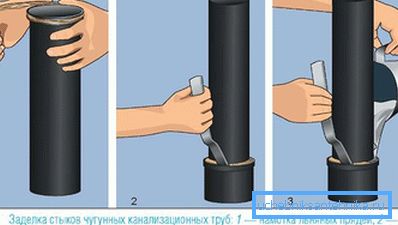

The bell-jointed pipe with a smooth end is made in the following sequence:

- chamfering on both pipes;

- on the end of the pipe without a bell, a restrictive collar and a heating sleeve are put on;

- a mandrel is introduced into the socket, which heats its inner surface;

- heat both ends before melting;

- quickly remove the mandrel and sleeves, and both pipes quickly connect until it stops;

- stand for several minutes until fully cured.

Glue

The glue method connects the pipe with an overlap at temperatures from +50 ° C, so that the glue in the cold does not lose its properties and be able to harden. Works should be carried out in a place protected from moisture. Before gluing, thoroughly clean the surfaces and degrease with a solvent. For gluing pipes with a difference in diameter of 0.6 mm, adhesives based on filling resins are applied and several layers are applied, giving time for each previous layer to set. For bonding pipes with a smaller difference using conventional glue, for example, based on methyl chloride, causing one layer and instantly connecting the parts to be glued.

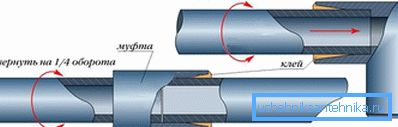

Glue joint is used in socket-type fasteners and socket joints. In flare glue is applied with a layer of 2/3 of the diameter of the pipe or 3-4 cm, depending on the requirements for mechanical properties. After applying the adhesive, the pipe is inserted into the socket and scrolled about 30-600 so that the glue is evenly distributed and comes into contact with the surfaces to be joined and then left for several hours until it polymerizes.

When coupling mounting glue is applied to the surface of the pipe, which are then inserted into the sleeve and fixed coaxially, kept for some time before setting, after which the mount is removed. They will be ready for operation after several hours.

Threaded

Removable connections made with a thread have high tightness, density and ability to withstand high pressures. They are not common in sewer connections and are used only in cases when it is necessary to ensure control of a certain section of the pipeline. In some cases, when it is not possible to make other joints of a non-separable type, threaded connections may be used that are put on the glue.

Couplings are usually used to ensure the same internal diameter of the pipe and not impair permeability. A sealant should be used to connect pipes: flax, linseed oil, white paint or putty.

First, the thread is coated with whitewash, and then a layer of flax is wound, starting from the second round of thread, with a thin dense layer. A minium is applied on top of the wound layer. In this case, the ends of the windings should not hang down. After that, the clutch is wound, and then tightly tightened with a key to the end. The other tube is screwed into the sleeve with the same applied sealing layers.

Tip! If the thread on one of the pipes is longer than the coupling one, then a fixing lock nut is used, which is screwed in before the sealant is applied, and then, after tightening the coupling, it is screwed tightly to the coupling.

Connection of pipes made of different materials

Usually, when switching from central sewer systems to domestic ones, it is necessary to use adapters from one type of pipe to another. This is usually a compound of cast iron and plastic. These materials have different mechanical and physical properties, so you have to take this into account when connecting. The main problem lies in the different coefficients of expansion of materials. Therefore, socket connections with rubber seals are used. To do this, the pipe is covered with a layer of glue and tightly pressed into the socket, or applied with tar resin, and then sealed with cement.

There are a large number of different sewage pipe joints and therefore it is necessary to know how to choose and implement them correctly, since the lifetime of the entire system directly depends on this.