How to connect two pipes of the same diameter: the actual

In this article we will look at the instructions for connecting one-dimensional pipes made of various materials. The topic of the article is interesting, since the market offers a wide range of different pipes, which differ from each other not only in their operational and technical characteristics, but also in different methods of connection into a single system.

But, before considering the features of the installation work, consider what kinds of plumbing accessories can be purchased.

Classification

All water pipes, in accordance with the production materials used in their manufacture, are divided into the following categories:

- metal modifications;

- polymer modifications;

- products from metal-based laminate.

Important: Each of these modifications is represented on the market by a wide range of products, which are characterized by one or another method of connection. Therefore, when planning the installation of a water supply system in your apartment or a country house, you need to take the choice of materials and methods of connection with maximum responsibility, since the price, durability and appearance of the finished system largely depends on this.

So, consider how the connection of the mixer to the pipe is performed independently.

Metal pipe docking

In the process of assembling metal (cast iron, steel and copper) plumbing and heating systems, threaded and welded joints are used.

Consider in detail each of these methods:

- Threaded installation, which, incidentally, is the connection of American pipes, this is a technology that allows to assemble water pipes from elements with identical diameters of a cross-section.

To do this, a thread is cut at the ends of both pipes, over which a special metal coupling - a fitting - is wound. Through special fittings, you can assemble both straight and curved plumbing and heating systems.

The fitting used on such constructions has an internal thread, while an external thread is cut on the pipes. If fittings for installation are purchased with already cut threads, then it will be necessary to cut it on the joined elements with your own hands using dies.

Among the advantages of the technology, we note the strength and durability of the finished result. In addition, if necessary, a threaded fitting can be unrolled and the entire structure can be disassembled in order to fix a breakdown or rework.

Important: As a rule, the thread on the pipes and fittings apply standard. But if foreign-made accessories are purchased from lesser-known brands, you need to make sure that the product will meet the metric type of thread.

- Installation of plumbing systems using welding is rarely used. The main disadvantage of a welded joint is the inability to do it yourself, since a professional welder with special equipment and experience in using this equipment can cope with such work.

The following types of welded joints are used for the installation of two one-dimensional pipes:

- transverse butt joint (without bore or with internal bore) with backing ring;

- longitudinal butt joint (without bevel or with bevel) with one-sided seam;

- cross butt with unilateral seam;

- unilateral angular;

- double-sided corner;

- overlapped bell

The butt joint is the most common, since the finished result is characterized by high strength, provided that the joined elements are correctly centered.

If a water supply system with an internal diameter of up to 500 mm is assembled, a one-sided joint is welded, and its strength is sufficient. If the diameter is larger, the root of the seam is welded inside, resulting in increased joint strength.

Weld is considered the optimal type of connection for the installation of industrial water supply, but is rarely used in everyday life because of the high cost of the finished version and constrained conditions for the use of the welding machine.

Brazing of copper components is a technology used in the assembly of premium plumbing systems.

The principle of installation is as follows:

- the ends of the joined elements are cleaned and covered with solder;

- the inner surface of the fitting is cleaned and soldered;

- the pipe is inserted into the fitting and heated by a torch;

- after the solder cools down, it turns out a strong and durable coupling docking.

Types of polymeric products

If the question is how to connect the HDPE pipe, then in this case the installation is much simpler than the assembly of a metal water supply system. No thread is cut on the plastic, and installation is carried out by two methods: by soldering or using fittings.

- Connection of HDPE pipes using fittings is popular when assembling domestic water supply and sewage systems. The relevance of the method is not surprising, since the fittings, regardless of the modification, can be installed even by a novice plumber.

Fittings, in accordance with the design features are divided into the following categories:

- Crimp Modifications - simple and yet effective and versatile to use mounting accessories. Special pliers are used for the installation, which allows to evenly distribute the applied force along the entire perimeter of the compression cuff.

- Press fittings - are distinguished by the greatest reliability, since they guarantee a complete absence of leaks.

Installation is performed using a special apparatus. Fittings of this type are installed, first of all, for the installation of plumbing, followed by incorporation into the wall or floor screed.

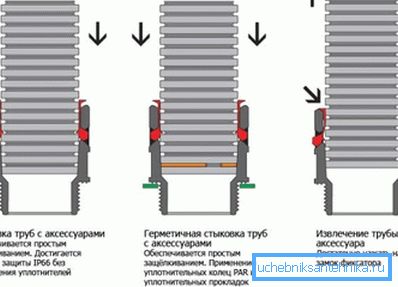

- Push fittings - this is the optimal solution if ease of installation is required. Connecting elements are used so that during operation it is possible to disassemble the structure.

- Welded connection of propylene pipes with the use of special equipment is carried out end-to-end or with the use of plastic fittings.

Butt-welding is relevant when the installation of water and sewer systems of large diameter. For a different type of welding, an electrofusion coupling or special fittings are used.

In either case, the joining surfaces melt, and as the plastic cools down, a reliable, almost monolithic joint forms.

Installation of metal plastics

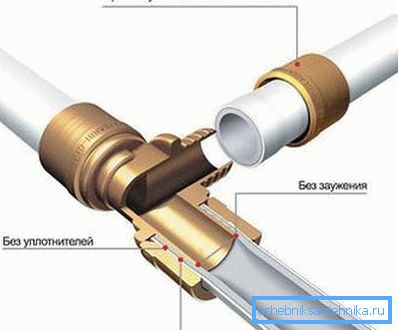

The joining of metal-plastic pipes is performed by the following connecting elements:

- Collet compression fitting fittings - in the process of installation are inserted into the hole with a shank, tightened collet and fixed cap nut. The shank of the connecting element is equipped with rubber sealing rings, which are compressed by a squeeze pipe and provide the required level of tightness.

- Fixed press fittings are a one-time docking accessory. The fitting shank equipped with sealing rings is inserted into the pipe as far as it will go. Then, using special tongs, a flexible cuff is crimped, which performs the function of a cap nut.

Conclusion

Now you know how to connect PVC pipes or their metal counterparts. The obtained information can be applied in practice, choosing pipes and connecting elements to replace the plumbing in an apartment or a country house.

More useful information can be found by watching the video in this article.