How to cut a pipe at 45 degrees

When installing the pipeline, it is often necessary to cut the pipe at an angle. Moreover, the angle should have exactly the degree that is necessary for the design. With improper production of the angle, it is impossible to make exactly the dimensions of the pipeline, which were supposed to perform. For example, the pipe will rotate 45 degrees during installation, therefore, you need to know how to cut the pipe at 45 degrees. For this we need marking tools, a grinder or a handsaw for metal.

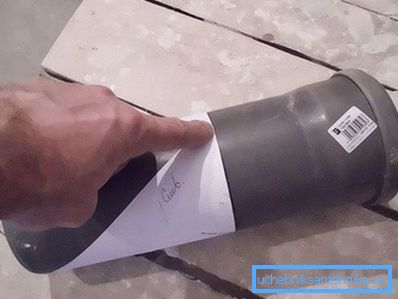

Markup with a sheet of paper

One of the easiest methods is to mark the corner with a sheet of paper. Square sheet fold strictly diagonally. We take the pipe and wrap it with a folded sheet so that the edges of the diagonals are facing each other. Thus, on the smaller side of the sheet, we have an angle of 45 degrees. We take any marking tool and mark the place of the future pipe cut along the sheet line. You can use a narrow tape to prevent the marking from being accidentally erased. This method of marking is convenient for a long pipe of large diameter, and the place of the section of which is somewhere in the middle.

Use of water tank

What to do if we are dealing with a pipe of small diameter, and it is necessary to cut the pipe at an angle somewhere near the edge? Come to the aid of a deep container filled with water. Before you begin, you must calculate the angle of inclination and make a mark on the container. Then we just have to gently lower the edge of the pipe into the water and tilt it towards the mark on the container. We pull out the pipe, mark the line of contact with water, and boldly cut by marking. This method is good at marking a large number of pipes. The finished template from the water tank will speed up the process of our work.

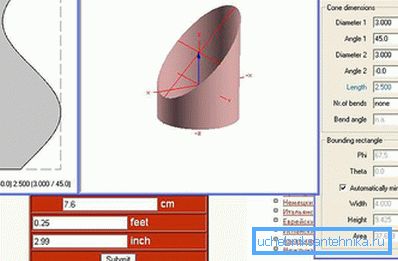

Computer program to help

I would also like to consider the method of markup using a computer program. This is a rather complicated method for those who are not used to working with a computer. It requires knowledge of the PC, the availability of software for scans and drawings. We begin work with the execution of the drawing, indicating the size of the circle and slope. We make the so-called virtual pattern.

Then, using the printer, we print the image on a sheet of paper. The larger the diameter of the pipe, the more sheets will be marked. Scissors cut all parts of the drawing and with the help of scotch tape, glue them. The finished template is applied to the pipe, and on the edge of the paper we make the markup. This markup method is considered one of the most accurate. If the computer does not have such programs, you can use the Internet. Online you can download the template for markup. It must also be printed out and cut out. The finished piece is wrapped around the pipe and perform the markup.

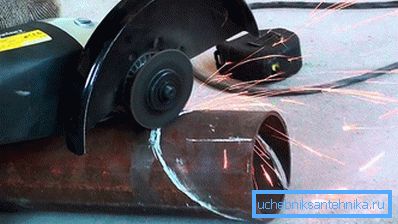

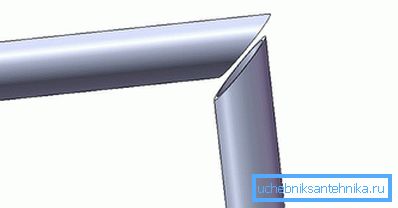

If the pipe is profiled

And here, for example, we have a profile tube, not a round one. Manual marking of the profile pipe can lead to large errors. The best way out of this situation will be a template made of the same profile of larger diameter. Take a small section of the profile tube and with the help of the protractor, we note the angle of 45 degrees. Cut off the grinder on the markup and grind the edges so as not to get hurt when working. Then we just have to insert a profile of smaller diameter into the template and, after making the markup, cut it off.

Video

Thanks to this video you will learn how to cut a pipe at an angle of 45 or 90 degrees using a computer program:

Cutting a profile pipe using a forty-five degree pipe cutting device: