How to cut the thread on the pipe at home

To date, most homeowners, conducting repairs in a house or apartment, are overwhelming for heating and plumbing prefer to do wiring with polypropylene, in extreme cases - with metal-based laminate. But water supply outside (especially, it concerns apartments in multi-storey buildings) is still performed by metal, therefore, the question arises how to cut the thread on the pipe near the wall.

Whatever you say, but it is quite difficult to do because of the restriction in free space, so we will draw your attention to some of the nuances of such production, as well as demonstrate the video in this article.

Thread cutting

Instruments

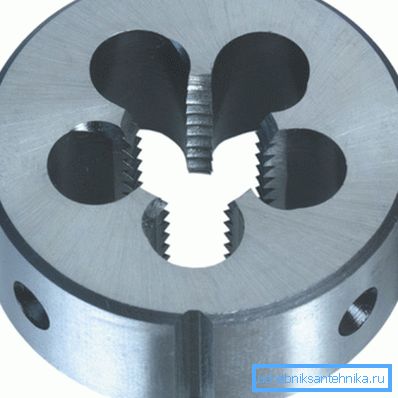

Explanation. Lerka or sweep is called a thread-cutting tool for pipes and fittings in the form of a thick plate with a threaded hole in the center. Where there are slots for the formation of cutting edges. Lerka, in contrast to the die, is an inseparable tool, therefore, the thread is more accurate, especially on blanks with a small section. Maybe for cutting the left or right thread, but there is also a universal option - marked with the marking LN.

- As you understand, the main device that makes threading on pipes is a meter, but by itself it is not effective, since a lever is needed for it to put it into action. You can immediately make a reservation that the lever should be specialized, for example, if you squeeze it with a gas key and try to cut the thread, then Lurka will most likely burst.

- The cutting tool is fixed in a die - this is a frame with handles - so, the frame compresses the prismatic or square gauge, enhancing its strength, and the handles, screwed on the sides, serve as a lever. But such a device is convenient in cases where there is room for levers, but if the disc is located against the wall, then they have to be constantly unscrewed and re-tightened. Therefore, it is much more convenient to use a pipe clamp with a ratchet, as in the photo above - the presence of a wall with one or even two sides (angle) in this case will not be a serious hindrance.

- An electrical screw die or machine for cutting threads on pipes is also a hand-held tool that can be used in any plane, besides the head can be inserted on either side, therefore, both sides are working. Thanks to the powerful gearbox, you practically will not adjust efforts when cutting threads, but its price, respectively, is also much higher than the same ratchet. Despite the versatility, such a tool, compared with the lever die, is quite cumbersome and requires a quick opening for cutting the thread on the pig.

Practical advice

First of all, the instruction requires to precisely cut the pipe, because otherwise the meter will move diagonally, therefore, the thread will turn out to be fuzzy, with a broken step, or you will not be able to hook on the edge at all.

Here, especially if the blank is located near the wall, no marking will help you - for an even cut you need to produce an accurate eye. Even if you did not succeed in an even cut the first time, then you can always trim the higher edge with the same disc so that an angle of 90? Is obtained with respect to the pipe wall.

It is very important to pay attention to the state of the metal - given that usually such works are done with old plumbing or heating, the walls can be corroded with corrosion, and the cut threads will make them even thinner. Therefore, you should either get to the living metal, as the masters usually call it, or even replace the old pipe with a new one.

On an even cut, you need to cut a chamfer, which will allow Lerka to cling to the metal, just try to keep the bevel uniform around the entire circumference - so the head will be wound smoothly.

Recommendation. For threading, it is imperative to lubricate the working disc so that the edge does not get torn. For this purpose, machine oils and greases are used, but practice shows that the best lubricant in such cases is raw lard, which is rubbed on the treated surface.

After you have made sure that the cut is smooth and the chamfer is cut correctly, lubricate the working surface of the blank (preferably with lard) and press a machine (thread-cutting pipe set) onto its end. After that, you apply the walls with the head to the cut end strictly at right angles and, pressing on from above, slowly, without sharp movements, begin to rotate the handle.

It is necessary to push as long as Lerka thoroughly bites the metal - for this you need to cut at least one and a half or two rings. After that, the pressure can be stopped - the machine will move thanks to the received hook.

After cutting the first steps, you need to scroll the machine in the opposite direction - this will allow you to chop the chips, because otherwise the movement will be very difficult.

In addition, do not strive to go through the entire remaining area after the hook at a time - after two or three turns, let's reverse to get rid of chips, and add lubricant as needed. If you use a ratchet, then before starting work, be sure to check its idling speed and, if necessary, adjust it with your own hands.

Conclusion

The technique described in this article is suitable for almost any ingot with a cross section of up to 1 inch, since cutting threads on a 1 2 (1/2 inch) pipe can be done in the same way as 3/4 inch and so on. On a larger pipe, the thread is cut either on a lathe, or a union (sgon) is welded to it. Have a good job!