How to defrost a water pipe

Russian winter frosts are a routine test not only for residents of our regions, but they are also a serious strength test for most categories of private and industrial communications.

In the event that when laying a pipeline to a house during the period of preparing it for winter operation, serious violations were made, you will sooner or later encounter the problem of freezing and, as a result, the need to become familiar with how to defrost a water pipe.

Causes of water freezing in pipelines

As already noted, the most likely cause of water freezing in pipelines is gross violations of the following requirements for the installation procedure:

- the laying of pipes did not take into account such an important indicator as the depth of soil freezing in the area;

- not enough effort was made to conduct external insulation of pipes laid openly or in special boxes;

- insufficient measures were taken to insulate pipes at the entrance to an unheated room.

In order to avoid all the violations listed above, you should take care in advance that the following conditions must be met when laying the pipeline:

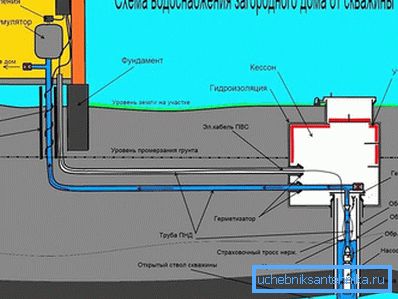

- In the case of underground pipeline installation, it is necessary to prepare a ditch for it in such a way that the depth of the pipeline slightly exceeds the level of soil freezing in the area.

- It is advisable to lay a water supply line away from existing reinforced concrete structures, the thermal conductivity coefficient of which differs from the same indicator for the soil. In this case, the probability of water freezing in pipelines is markedly reduced.

- It is recommended to lay the pipelines together with the heating cable, which (despite the general increase in the cost of work) will finally eliminate the problem of pipe freezing.

- Zones of the pipeline through the walls of the buildings must be insulated with glass wool, thus avoiding direct contact of the pipe with the wall.

- To reduce the likelihood of pipe freezing, their diameter should be at least 50 mm.

- When installing pipelines in the open air and in unheated premises, it is recommended to use polyethylene pipes that can withstand several cycles of freezing and defrosting (for comparison, polypropylene pipes after 2 such cycles usually become unusable).

- With seasonal use of water supply during the winter idle time, it is necessary to completely drain the water from the system.

Defrosting methods

In this chapter, some methods of defrosting pipes will be considered taking into account the possible difficulties of their implementation. But regardless of the method of heating pipes you choose, in all cases the following general rules must be observed:

- In the process of heating the pipes, it is necessary to keep the valve valve open so that the thawed water can flow freely from the pipeline.

- It is undesirable to start defrosting water from the middle of it.

- The generally accepted procedure for heating is from the valve tap towards the riser. When working with sewer pipes, the order of heating is reversed (from the riser to the valve).

All known methods of defrosting pipelines can be divided into methods of external exposure to the heated area and methods of internal heating. First of all, we investigate the methods of warming pipes of a frozen conduit due to external influence.

The simplest device that allows for effective external defrosting of pipes is an electrical cable, for heating of which you will need one of the devices listed in the list below. It may be:

- ordinary blowtorch (gas torch);

- professional building hair dryer;

- a device that works on the principle of electrical heating (a spiral from an old plate, for example).

Using any of the above devices, you can continuously influence the pipeline section to be defrosting. Evidence that, as they say, “the process has begun,” will be the emergence of a trickle of water at the outlet of the supply valve.

Tip! The safest and most efficient way of external defrosting of pipes is considered to be the use of a special heating cable or electric heating tape (In the latter case, it is enough to wind the tape or cable onto the frozen section of the pipeline and plug them into the network).

If necessary, the external defrosting of the pipeline from steel pipes is often used and the method of connecting the working ends of the welding machine to the boundaries of the frozen section. In this case, the whole process of heating will take you no more than 2-4 hours (depending on the length of the defrosting area). At the end of defrosting, be sure to inspect the pipeline for leaks, which may “declare” in the most unexpected places.

How to defrost a plastic pipe

Nowadays, traditional steel pipelines are everywhere being replaced by modern water lines assembled on the basis of plastic pipes, which are not subject to the corrosion habitual for many and do not collapse when they freeze.

But in the case of the formation of an ice block in plastic, none of the methods of external influence listed by us are applicable to them. Indeed, the use of open fire to heat a plastic pipe will cause its destruction, and the use of external heat (building hair dryer, for example) is, as a rule, ineffective due to poor thermal conductivity of the material.

All electrical methods of heating such pipes are also absolutely useless, since all types of plastic do not conduct electrical current. By the method of mechanical action on the ice “jam” (by inserting a steel bar into the pipe), it is possible and possible to pierce a small cork, but there is a risk of damaging the walls of the plastic pipe.

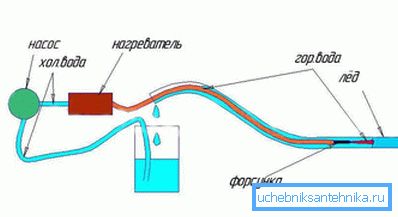

From all this it follows that the only real way to defrost a plastic pipe is to pour hot water inside. Immediately, we note that this technique is quite effective, but its use is advisable only on pipes of small diameter.

With this method of defrosting hot water is supplied directly to the place of freezing as follows:

- A pipe or hose is selected from a material of greater rigidity, but slightly smaller in diameter.

- For defrosting a straight pipe section, it will be more convenient to use a metal-plastic pipe. Well, in the case of a pipe section bent along an arbitrary curve, you will need to use a fairly rigid but flexible hose of smaller diameter.

- In the course of the narrative, we note that typical watering hoses for this operation will not work, since they soften noticeably from hot water. Gas or oxygen welding hoses are best suited for defrosting.

The use of metal pipes

You will need metal-plastic pipes if the diameter of the frozen pipeline exceeds 20 mm. Before the start of work, such a pipe should be gently straightened, after which it will be possible to smoothly move it through the pipeline, bringing it all the way to the ice jam.

After that, it will be possible to start pouring hot water into it, trying to keep the temperature at a high level.

After some time, the thawed water will begin to flow out of the gap formed at the joining point of the pipes; so in this place an arbitrary capacity for collecting waste should be installed. As the mash melts, the metal-plastic tube will more and more be pushed into the depths of the freeze, up to the complete removal of the ice plug.

Tip! The considered method is good for the case when an ice block formed near the point of entry of the probe into the pipe. In the same case, if the pipe is frozen at a great distance from the house and has many turns and bends, it is unlikely that a metal pipe can be pushed into it.

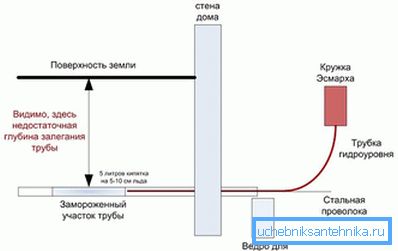

For this situation, there is another way to defrost the pipeline - using the Esmarch cup. When implementing this method, as a rule, the following manipulations are carried out:

- First of all, any type of hydro level is prepared, a wire coil of 2-4 mm and an Esmarkh circle (a device for cleansing enemas).

- Then the end of the hydraulic level tube is taken, to which the wire from the previously prepared bay is attached in one way or another. In this case, it is necessary to ensure that the tip of the wire is tightly pressed to the tube of the hydraulic level and does not interfere with its progress along the defrosting channel.

- Pay attention to the fact that the tip of the tube protrudes 1 centimeter from the place of fixing the wire.

- After that, we connect the return end of the hydraulic-level tube to the drain nozzle of the Esmarch's mug and begin to gently push the entire structure into the defrosting tube until it stops against the ice plug.

- Now it will be necessary to pour boiling water into the Esmarkh mug and fully open the water supply valve.

- As the ice plug melts, you should push the tube in the direction of travel.

- At the junction of the two tubes, you need to set the capacity of the appropriate size.

The described method of defrosting the pipeline is quite effective, but it will require some time-consuming. For one full hour of work, you will be able to free an area of no more than 0.8-1.0 meters from ice.