How to embed a tee in a plastic pipe

When operating modern water mains, it is often necessary to connect additional household appliances (washing machine or dishwasher, for example) to them. In this case, there is no way to do without the so-called fitting inset into the existing pipeline, which can be organized with the help of a special tee, which ensures a branch from the main pipeline.

But before embedding the tee into a metal-plastic pipe, it is advisable to familiarize yourself with the existing types of fittings, as well as with the order of their arrangement.

Types of fittings

When inserting a fitting-tee into a cut metal-plastic pipe, as a rule, such well-known connection design methods are used, such as crimping, crimping or fitting to threads.

In accordance with the technique used, two types of fitting tees can be used, namely:

- Compression.

- Crimp.

In addition to these basic modifications, composite tees can also be used for tapping into metal-plastic pipes, the working parts of which are designed for various types of joints.

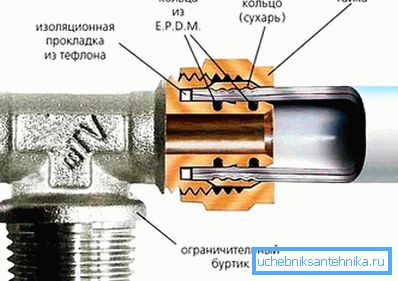

Such a variety of connections used allows working both with detachable (crimp nut and thread),

and with one-piece (press sleeve) wiring diagrams, which increases the functionality of the equipped node.

Thus, when using a tee with one internal thread and two compression nuts, it will be possible to connect in the system not only a washing machine or a dishwasher, but also any measuring device with a threaded nipple.

Tee structures and their installation

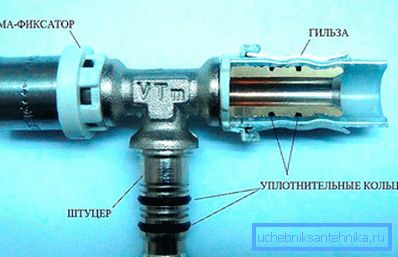

Most of the typical fitting tees used when inserting into metal-plastic pipes, are made of brass or bronze by injection molding. The sealing elements used in them (locknuts and compression rings) are also made of bronze. Certain types of such seals can be made from rubber, as well as from modern plastic polymers.

Tip! In the construction market there are cheaper silvers made from silumin, but due to their low quality they are not in demand. Professionals do not use such fittings.

So, press sleeves tees, embedded in metal-plastic pipes, are made, as a rule, of stainless steel sheet. Their brass cast housings are usually equipped with plastic resin seals.

When a household insert tee in metal pipes most often used connection crimp or crimp type. For their formation in the first case, used clamping fittings, and in the second - press fittings.

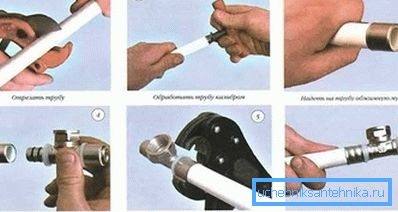

Technological techniques used in the preparation of these types of joints, have many similar features. The implementation of the first of them involves the sequential execution of the following installation operations:

- first, the pipe is cut at the insertion point at an angle of 90 degrees to its longitudinal axis;

- then both of the resulting butts are ruled by the so-called caliber, which gives the cuts a working look (they should not have any irregularities and burrs);

- after that, at the pipe ends, locknuts with a compression ring-sleeve are placed, after which both nipples (internal fittings) of the mounted fitting are successively attached to them;

- at the final stage of work, it will only be necessary to fix the pipe parts of the connections on the nipples, sealing their joints using crimping sleeves.

Immediately, we note that in order to form a reliable collet connection, the body of the mounted fitting must be held during crimping with an adjustable wrench. Well, to tighten the crimping nut is best to use the wrench.

The order of formation of the press-fitting articulation differs from that already considered by us earlier. The usual keys are not useful here, since a special tool is needed - press-ticks, with the help of which the tubes inserted into the tee are crimped. This is a non-separable connection.

To obtain a standard threaded connection, the mounted fitting is simply screwed onto the pipe bend, the working section of which (with a previously prepared external thread) is pre-sealed with FUM tape. Once again, we note that the threaded connection of fittings with metal pipes is used extremely rarely.

Video

Watch the training video on working with plastic pipes. You will get acquainted with the installation of press fittings, cutting pipes and see how to work with the tool: