How to insulate a water pipe

The effects of cold winter temperatures can adversely affect the plumbing system. The pipeline system, not insulated with special materials, may collapse after the onset of the first cold weather. That is why many owners of private homes are increasingly interested in how to warm the water pipe.

Warming Why is it necessary

Is it necessary to warm the water pipe? To answer this question, it is necessary to note the main nuances of the pipeline:

- Water entering the pipe under the influence of low temperatures freezes. As you know, when moving from a liquid to a solid state, water is able to expand. This creates a certain pressure and pressure in the pipes. Subsequently, this will lead to a complete rupture of the pipe. To prevent this, our main task is to prevent water from freezing in the pipeline.

- An additional advantage of insulation can be considered the ability to save heat and heat in pipes. This leads to additional cash savings.

Requirements for work

To carry out the insulation of water pipes with your own hands, you should follow certain rules of work:

- Determine the depth of the running water pipes. Ideally, they should be located well below the depth of freezing of the earth’s surface. In this case, the danger of freezing water in the pipes does not threaten you. However, it is technically difficult to install the pipeline at the required depth. If the depth of pipe laying is less than the depth of frost penetration, it is necessary to take care of the insulation of the water supply system.

- To begin with, it is necessary to determine which sections of the pipeline are more exposed to negative temperatures. There should be made insulation first. Usually there are 2 areas most prone to cold: the outer part of the water supply system, and pipelines laid in rooms in which the heating system is not installed.

- When conducting insulation of the pipeline system outdoors, it is necessary to work not only with pipes, but also with all the components of the water supply system (couplings, partitions, pumps, etc.). They also need to undergo the procedure of insulation.

Choosing insulation

One of the factors to achieve success in the process of insulation is the material - insulation. How to choose it correctly and not make a mistake? Consider the most common types of materials for insulation:

- Glass wool. The most familiar and acceptable type of material. Thanks to the rolled form of release it can be applied to warming not only pipes, but also components of the pipeline. The optimal price makes this type of insulation the most popular. It is made of special fiberglass cloth. To achieve the greatest effect of heat preservation, it is possible to additionally produce insulation with roofing material or fiberglass.

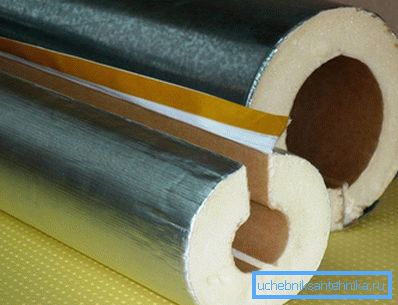

- Basalt cylinder. It is a specially made basalt fiber case. The material has a high density, which provides optimal parameters of heat preservation. A lot of cylinder modifications are made, so when insulating you can choose any cylinder diameter. For increase in service life of a product the cylinder becomes covered with the reinforced foil layer. For insulation of individual parts and partitions of water supply, special components of the cylinder are produced. For additional heat preservation when installing cylinders, it is recommended to use roofing felt.

- Styrofoam. One of the most commonly used materials. Also available as a cylinder for pipes. For insulation of additional parts of the pipeline, joints and corners produce special corner elements of foam. It can be used for thermal insulation both outdoors and inside.

- Paint for thermal insulation. Special substance is gray. It has a pasty shape. On the surface of the pipe is applied with a spray. The level of insulation is regulated by the thickness of the applied layer. The material is not subject to external damage and corrosion.

Types of thermal insulation works

All works on thermal insulation of the pipeline are divided into 2 categories:

- Work on the site of the water supply, passing under the ground.

- Work on the surface of the earth.

Warming of the underground part of the pipeline

It is at this stage of work that difficulties may arise. This is due to the inconvenient location of the pipeline, which greatly complicates the work.

Consider the main types of thermal insulation works:

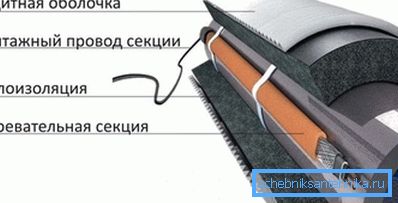

- Insulation by heating pipes with cable. In this case, the pipe wrapped with a special cable with a small capacity. It is possible to use both external and internal pipe entanglement. The main advantage of this method is that the cable can be adjusted. So, during the warm period there is no need to heat the pipes. Therefore, the cable can be included with the onset of cold weather. With this method of insulation, you can lay the pipeline at a relatively small depth (about 50 cm).

- Air way of warming. It is to prevent the flow of cold air from the earth’s surface to the surface of the pipes. To do this, it is necessary to build a barrier that prevents the passage of cold air masses into the earth. It can be made of foam or basalt.

- Work with high pressure. To ensure a constant temperature in the pipe, it is necessary to create a high pressure in it. For this, a special device, a receiver, should be mounted in the pipeline. With the help of constant pressure in pipes it is possible to achieve heat retention.

Insulation of the pipeline on the surface of the earth

This stage of work is easier and does not present any difficulties.

For indoor use it is recommended to use standard thermal insulation materials.

Installation method:

- If you work with insulation in the form of a cylinder, you must take its components and attach it to the pipe. Tip, there should be a slight displacement of materials. Secure the cylinder with tape.

- When working with fiberglass material is wrapped around the pipe and strengthened with adhesive tape.

- You can further enhance the effectiveness of thermal insulation with an additional layer of roofing material.

- Tip on corners, joints and various transitions in the pipeline. They must be insulated using special cylinders made of insulating materials.

Tip! Particular care should be taken at the junction of the water pipe and the building. It is recommended to use a cylindrical insulation with an additional layer of insulation.

The remaining voids in the course of the work should be filled with foam.

Video

For more information about the methods of conducting insulation of the pipeline can be found in the following video: