How to insulate pipes in the ground

The times have already passed when the main source of water was a well with a bucket on a chain. Today, water enters the house through the plumbing system. In this case, the source may still be a well or, for example, a well.

Water runs into the house through pipes that are located on the street below the ground. If such a system is used only in the summer, then special efforts should not be made to warm the pipes. However, if you plan to use the water supply system in the winter, then you need to take into account the fact that in some areas the freezing depth reaches two meters. Pipes that are poorly insulated may freeze through and, as a result, become unsuitable for further use. For this reason, it is important to know how to insulate pipes in the ground. Let us examine the basic requirements that apply to modern insulation.

Insulation Requirements

For housing to be comfortable, all communications should work properly. This also applies to the water supply. If the pipeline breaks, repair will require substantial costs. For this reason, it is important to pay attention not only to how to insulate pipes, but also to the quality of the selected insulation.

Below are the basic requirements that should be guided when choosing insulation:

- Affordable price. In the question of prices should find a middle ground. You should not buy the cheapest and most expensive material. If you save, insulation will last only one or a maximum of two years. Accordingly, it will have to be replaced regularly.

- Tightness. It is extremely important that the insulation does not pass moisture.

- Durability. The better the material, the better its technical characteristics. Accordingly, this indicator will directly affect the quality of pipe protection.

- Fire safety. The heater chosen by you should not possess property of self-ignition. Therefore, a material that does not support combustion will be an excellent tool for pipe insulation.

- Easy installation. Most people who are engaged in pipe insulation themselves are not professionals, so you need to choose a material that does not create additional difficulties during installation. These are, perhaps, basic requirements. Next, you should pay attention to performance.

Operational and technical characteristics of insulation

There are important performance characteristics that are important to consider when choosing insulation to ensure that the insulation of a water pipe in the ground is as correct and efficient as possible:

- Resistance to adverse environmental effects.

- Low thermal conductivity.

- High level of heat saving.

- The ability to withstand the operating temperature without using any other insulating material.

So, if you want the work to insulate pipes in the ground as efficiently as possible, then when choosing a thermal insulation material, it is important to follow the above requirements. Now we should consider the types of insulation, which are fully or partially meet these requirements.

Types of insulation and their features

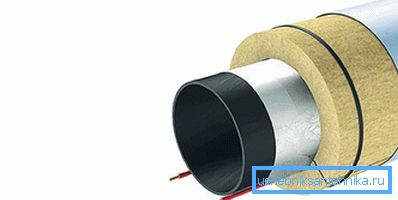

Basalt insulation. This insulation has a cylindrical shape, so you can easily carry out installation. To protect the fiber itself, it is covered with a thin layer of roofing material, glass roof covering or folgoisol. Despite the practicality of this type of insulation, its price does not suit everyone.

Glass wool. This type of insulation material is mainly used for insulating metal-plastic pipes. The following glass trademarks stand out clearly here: Isover, Knauf and Ursa. Glass wool has a fairly low density, so for its use it is necessary to additionally stack fiberglass or roofing felt. As a rule, this leads to additional waste.

Styrofoam. This material is most popular for self-insulation of water pipes in the ground. Polystyrene shells can be of two types, namely with an outer coating and without it. This insulation can be used repeatedly both indoors and outdoors.

Heating cable. The heating cable is an innovative solution that allows, when used correctly, not only to warm the pipes, but also to defrost them. To make the insulation of pipes with the help of a heating cable with their own hands is quite capable of everyone

Heat insulation paint. This type of insulation is a pasty mass. It is found in white and gray. Its production is carried out on the basis of varnish or water. In this case, special fillers such as acrylic dispersions are added to the mixture. Heat-insulating paint is applied to the pipe with a spray, it allows you to achieve economical consumption, as well as a uniform application to the surface. Paint has anti-corrosion property, and also copes with temperature drops. According to research, one layer of heat-insulating paint can completely replace glass wool or polystyrene foam.

Stages of work

It should be understood that regardless of the type of insulation, the principle of their action is the same. In most cases, the choice may be influenced by other factors, such as the location of the water route. If this place is exposed to a large amount of moisture, then an appropriate material is required, and vice versa. Now we will consider some features of works on thermal insulation of water pipes.

Pipes are wrapped with insulating material, the latter, if necessary, secured with plastic tape. After waterproofing is made. If pipes pass underground, it is not recommended to use glass wool or similar material. This is due to the fact that you have to do two layers at once: the second will play the role of a casing. As a rule, this leads to additional labor costs, and the project itself will turn out to be very expensive.

Tip! The density of glass fiber materials is very low. Therefore, during the backfilling of the trench, the material will simply shrink under the natural weight of the soil. This will lead to a reduction in the life of the insulation, and the pipe itself will be poorly protected due to the wrong insulation.

If the pipe is filled with layer-by-layer tamping, then this method can significantly increase the efficiency of insulation.

This can be seen by considering an example: in the event that the trench is just to fall asleep and leave the ground loose, then autumn rains will quickly soak into the soil, as a rule, the water gets to the insulation, and it in turn is unlikely to dry out for winter. For this reason, it is recommended to thoroughly ram the earth in trenches after the insulation of the water pipes has been completed.

As for polystyrene foam and basalt fiber, their installation is carried out quite simply and most importantly quickly. With a shift of 100–200 mm, half of the expanded polystyrene of the required diameter is put on the water pipe. To keep it, you can pre-secure one half with scotch tape. If your pipeline system has corners and knots, then it is recommended to use a shaped shell. As for the benefits of this insulation, here it is necessary to pay attention to an obvious factor.

The water absorption level of polystyrene foam during the day is only 0.5–2%. As a rule, this material does not absorb moisture, respectively, is not destroyed. Even if water penetrates through the soil, polystyrene foam will perfectly protect pipes from moisture. In some cases, this insulation is used in unheated rooms.

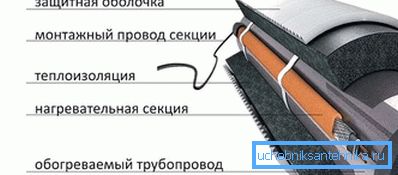

Now we will consider another technology of pipe insulation using a heating cable. As mentioned above, it is an expensive pleasure, but if you install it yourself, you can save money. There are two options for its laying. The first involves laying a cable inside the pipe, but this method requires professional skills. For this reason, the second method is more relevant, namely laying the cable on top of the pipe.

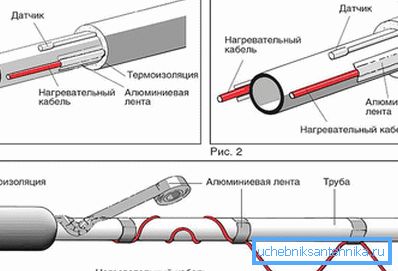

When using this method there is no need to bury water pipes to a depth of two meters, it will be enough fifty centimeters. To perform the work you will need the following set of building materials: waterproof insulation, foil and plumbing tape, as well as self-regulating cable. The power of this cable should be at least 20 W per linear meter of pipe.

So, the whole process of pipe insulation can be divided into the following six steps:

- During the entire distance of the pipe from the well or well and right up to the house, you need to glue the foil tape in a spiral. To keep the wire well, do not glue the tape too tightly.

- Then the cable itself is laid spiraling in steps of 100-150 mm.

- To fix the cable, foil adhesive tape is glued over it again.

- After along the pipe insulation is cut and wrapped around it. To prevent the appearance of cold bridges, during operation it is important to control that all the joints between the insulation and the wire coincide.

- Then the sanitary tape, which tightly wraps the whole pipe on top of the insulation, is taken. This will completely prevent the penetration of water through possible gaps.

- When you have reached the entrance of the pipe to the house, here you will need additional use of insulation.

In addition to this system, it is recommended to set temperature collection points. Four such sensors can be installed throughout the entire route.

Monitoring can be performed automatically or manually. For example, if the temperature drops below + 5 ° C, then a message will be sent to your mobile phone or email. Moreover, you can set a specific temperature barrier, when reached, the heating cable will turn on or off.

Tips and tricks

- It would be nice to draw a detailed scheme of the underground water supply. Pay special attention to the joints and joints. Just one drop of frozen water in the thread can break it. Moreover, lay pipes that do not corrode, such as metal-plastic.

- The pipes should be insulated along the entire length, without missing a single meter. The same applies to basement and unheated premises.

- One of the simplest methods of pipe insulation is the use of PVC sewer pipes O100–150 mm. They should be pre-sawed, then fixed with a scotch tape on the pipe, and the emptiness filled with foam. So that the foam does not come out through the holes, you can glue them with tape.

- One should not forget about the lovers of warmth in the winter season, for example, moles, rats and other rodents. As a rule, they can settle near warm pipes. Therefore, the insulating material must be protected from them. Otherwise, they will bite the insulation, and in the spring you will have to warm the water pipes again.

So, we looked at how to insulate water pipes underground from different sides in great detail. Remember that you should not postpone this work until later. As a rule, frosts come unexpectedly. Stretching time, you can be in a not very favorable environment. It would be more prudent to think about warming in advance, in this case it will be time to correct minor flaws and make the pipeline insulation as efficient as possible.

If in the course of work or only planning you have any questions, you can contact our experts who will kindly answer all your questions. Moreover, if you already have experience in weatherization of water pipes, then we will be interested to learn about new methods. So leave your comments at the end of this article!

Video

Features choice of insulation considered in the following video: