How to insulate the ventilation pipes on the roof

Arrangement of various kinds of engineering communications provides for well-known ventilation pipes installed on the roof. This technique has its own special moments and needs strict adherence to all technological processes of installation. Usually it is used in a private house. In this way, exhaust ducts are equipped for ventilation of rooms, installation of a sewer riser, and ventilation of the attic.

How to insulate the ventilation pipes on the roof, and what materials are best for this?

Ventilation pipes on the roof should be placed in such a way that exhaust air can be removed through them without much difficulty. Moreover, its height and diameter are determined on the basis of the required performance.

Tip! The simplest type of device is considered the withdrawal of pipes through the roofing ridge. In this case, the main condition is considered to be properly performed insulation to prevent the formation of condensate.

Without additional warming, moisture will accumulate in the inner sections of pipes and flow along the walls, penetrating into all leaking places. This will cause the appearance of damp areas on the walls and ceilings, their premature destruction. Yes, and your air duct may also suffer from condensate manifestations. To avoid all these unpleasant moments, you should take care of the device insulation around the ventilation ducts.

On which areas it is necessary to perform insulation

So, is it necessary to warm the ventilation, and in what places is it necessary to do it without fail? The answer suggests itself - you should perform the insulation in those places where there is a rapid cooling of air masses. The ventilation pipe laid through a solid wall must be passed through a special heat-insulated liner and insulated to the very deflector element. In private homes, such pipes pass through attics and are brought out through the roof. And their warming is carried out from that point where noticeable cooling begins. Moreover, it is recommended to slightly move the insulating boundary in the direction of a warm room. This is in case the frost will be more severe than usual.

Materials for insulation

It is necessary to consider all acceptable ways of warming and choose the most suitable of them. It is important that the method we choose meets certain requirements:

- Good thermal insulation properties.

- Fire safety. The material should not be classified as combustible.

- Relatively low cost.

We will analyze only those options when the channels are insulated from the outside. After all, it is not always possible to dismantle the structure, and the inner diameter due to insulation will decrease significantly. So what is the best way to do such work?

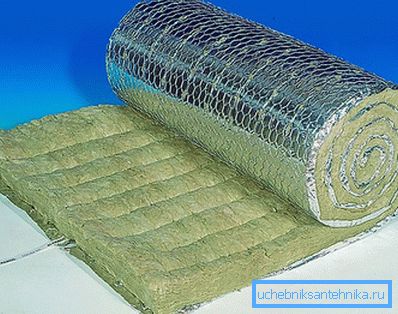

During operation, the material is somewhat compacted, forming gaps in the insulating layer. If moisture penetrates the insulation layer, it also loses its properties. The best solution is the use of corrugated pipe, which is based on cotton wool. But this method is good at the zero point of the construction of ventilation pipes.

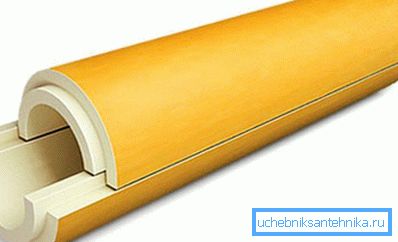

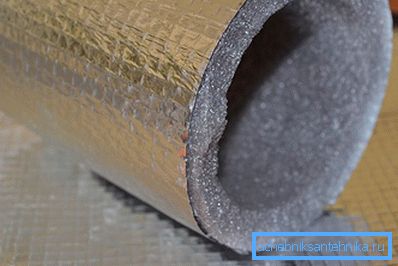

You can apply the shell of polyurethane foam and polypropylene. Such materials are stronger than polyfoam, and are more expensive. In the work they need a bandage, performed by ordinary wire for knitting. The manufacturer produces such insulating structures in the form of tubes of different diameters, having cuts. Such blanks can only be put on the pipe, and the insulation is ready. The material is cheap, able to withstand moisture and small mechanical stress.

Remember! Effective work of your system of ventilation depends on correctly chosen heater.

Video

This video will help you understand what and how best to do, equipping the ventilation of a private house: