How to make a chimney from a ceramic sewer pipe

Among the materials used in the installation of chimneys of heating systems, we can distinguish ceramic sewer pipes. This is a vivid example of inappropriate use of material, when it is not at all inferior to samples intended for this purpose. In order to be able to understand all the intricacies of the installation work, we will learn how to make a chimney out of a ceramic sewer pipe.

Material description

First of all, it is worth saying a few words about what the material in question is, since the features of the installation will largely depend on it. Ceramic pipes are used in construction relatively recently, but, thanks to the remarkable performance characteristics of the material, their use can be seen more and more often. Among the most significant features of such pipes can be mentioned:

- Versatility of use. Ceramics can be used in heating systems regardless of the fuel used, from gas boilers to fireplaces and stoves using wood or coal.

- The inner surface of ceramic pipes is smooth, making the passage of smoke easier, which increases the craving.

- Ceramics is not exposed to moisture, high and low temperatures and is chemically neutral.

- The material in question does not burn, which makes it one of the safest.

- Ceramics to some extent can retain heat, and thus increase the efficiency of the entire system.

Tip! Due to the smoothness of the surface, the formation of soot inside the pipe will be minimal, and if necessary, such pipes are easy to clean.

According to its technical device, chimneys made using ceramic pipes are the following:

- The central part is a ceramic pipe.

- Thermal insulation layer - basalt wool.

- The outer layer - blocks of lightweight aggregate or similar in material characteristics.

It should be noted that along with the obvious advantages, the technology under consideration can be noted a number of properties that can be mentioned as disadvantages. These include:

- Chimney using ceramic pipes will have a rather impressive weight.

- Work with the material and the installation technology itself requires certain skills, and therefore it is unlikely that they can be installed by hand without additional training.

- The use of ceramic pipes makes it impossible to manufacture chimneys having a complex shape.

- A chimney made using ceramic pipes will have a rather significant price.

However, despite all the shortcomings, the use of ceramic pipes for the installation of chimneys is fully justified.

Installation procedure

In order to understand the nuances of the installation of a chimney made of ceramic pipes, the process must be considered in detail.

- First, the base is prepared. It should be noted here that in view of the impressive weight of the whole structure, its installation will require its own foundation. For this, the floor at the installation site is dismantled, and the space required for installing the chimney is filled with concrete and leveled. For greater strength, the screed is reinforced with steel reinforcement.

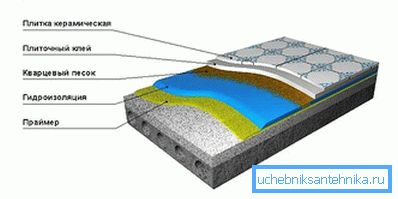

- After solidification of the foundation, it must be covered with a layer of waterproofing.

- Next, the main claydite-concrete block is mounted, in which tanks are installed so that condensate formed during the operation of the chimney is collected inside without destroying the structural elements.

- The first elements of a ceramic pipe are installed inside the unit, equipped with special inspection openings to allow maintenance of the chimney.

- Between the outer surface of the ceramic pipe and the inner surface of the blocks, there is a layer of basalt cotton wool, which will serve to ensure the thermal insulation of the chimney.

- Further, all subsequent blocks and parts of the pipe are laid in the same way. The blocks are interconnected with cement mortar, and the elements of the pipe are put on a heat-resistant sealant.

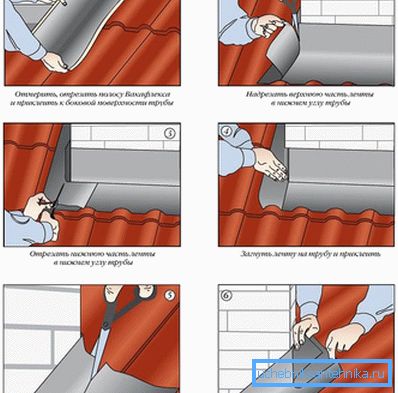

- In the place of passage of the chimney through the roof surface it is necessary to perform additional waterproofing.

- At the end of the work, the part of the chimney protruding above the roof plane must be equipped with a special protective casing. To him, in turn, is additionally mounted protective umbrella that protects the chimney from precipitation and mechanical pollution.

At this basic work on the installation of a chimney made of ceramic pipes can be considered completed. As can be seen from the above material, the implementation of the plan is not an easy task, but with proper preparation and some experience, it is quite possible for independent implementation.