How to make the connection of plastic sewer pipes with cast

Making repairs in the house or in the apartment, there are situations when it is necessary to change the old pipes. Usually, pig-iron ones are replaced by plastic ones, and at the same time they have to be connected with each other. In this article, we will consider the connection of plastic sewer pipes to each other and to cast-iron ones.

Plastic and plastic

The most popular in this market today are polyvinyl chloride and polypropylene products. This is due to their durability and throughput, which is many times higher than cast iron. Now we learn how to connect sewer plastic pipes, for which there are several ways:

| Adhesive |

|

| Welding |

After the polypropylene hardens with an airtight weld, the assembly cannot be disassembled. |

| Using compression fittings | You can connect the pipes of small diameters with your own hands due to the compression sewer fittings of a special construction, while welding and glue are not used. They will ensure the required tightness of the unit. To check the quality of the connection is enough to try to scroll the details among themselves. |

Tip: before finally settling on one or another method, conduct a series of experiments to be confident in your abilities.

Plastic and cast iron

Now we will look at how to connect a cast-iron sewage pipe with a plastic one, which is often found during repairs in apartment buildings. There is 1 way using press fitting and 4 without using it. In any case, after reading the article, you can create a reliable connection yourself.

We use rubber gasket

When, after removing the old cast-iron pipe, the inner surface of the socket remained flat, it is possible to use a special seal. In this case, the plastic will enter into it by 30-80 mm.

The option allows you to quickly install and continue to operate the sewage system. The service life of such a compound is up to 8 years.

Typically, the sewer riser has 2 outlets - the first one is O100 mm, the second one is O50 mm for drainage.

Connection instructions are as follows:

- Clean joints from dirt and rust..

- Apply a layer of sealant to the outside of the rubber junction..

- Insert the rubber adapter into the mouth of the cast iron socket..

- Fit a new tube into the cuff..

If there is no socket, a plastic adapter is used.

In this case, do the following:

- Cut a part of the cast-iron pipe with a grinder and align the edge.

- Put on this part of the rubber adapter.

- Smear the edge with a sealant.

- Put the sealant lip on top of the pipe.

Tip: transitions and cuffs should fit the size of the piping. The junction technology is the same for all diameters.

Linen winding

This connection of cast-iron and plastic sewer pipes is often used when joining the first, but it is also suitable for our case.

You should do the following:

- Wind a plastic reel on the plastic pipe at the junction point in several layers, its price is small. Sorry for her in this case is not worth it.

- Push a narrow spatula or a wide screwdriver into the gap between the products. Because of this, the method was called chasing.

- Smear a few times the transition to the cast-iron polymer cement mortar consisting of cement, water and PVA glue.

- Operate sewers can only be a day.

Such a joint will be quite reliable. Although today replaced by silicone sealant, linen winding is often used when docked under a washbasin or sink. If there are leaks after a time, it is not associated with this node.

Apply sanitary silicone

Usually, the method is used when the joint of a plastic pipe with a cast-iron pipe has a gap up to 2 mm wide. At the same time pay special attention to the tightness of the joint at the bottom.

In this case, you need:

- Dry the joint, for which it is best to use a building dryer.

- Push the silicone into the slot with a construction gun.

Tip: the deeper you can push the silicone, the connection will be more reliable.

- Wait until the silicone layer dries, which usually takes 3-5 hours. Consider that the thicker it is, the longer the drying time will be.

Tip: It is not recommended to use the sewer until the silicone is completely dry.

Combined methods

To improve the reliability of the connection between plastic and iron use a combination of methods:

- For sealing a large gap, use a rubber gasket along with a caulking.

- When using corrugations to connect the toilet to the system, they combine a caulking with flax underwrap and sanitary silicone, which is used to coat rubber seals and a cast iron crosspiece at the interface.

- Instead of a polymer solution, silicone sealant is often used.

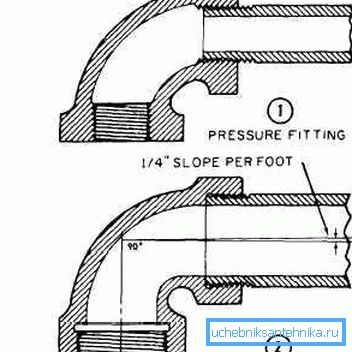

Press fitting

In this case, use fum-tape or tow.

Technology works as follows:

- Cut the old pipe together with a grinder or unscrew the coupling installed on the cast iron pipe.

- Grease the edge of the pipe with grease or oil.

- Cut the thread with a thread cutter, wipe the place and wind the fum tape or hemp on it.

- Grease the reel with silicone.

- Screw the press fitting onto the threads with your hand (do not use a key so that it does not burst). You can then tighten it after turning on the water supply, if you need to stop the leakage.

Tip: Do not screw the PVC fitting on the metal.

Conclusion

In this article, you learned how to interconnect plastic sewage pipes, as well as plastic and cast iron pipelines. It was told about the methods often used for this, where press fittings, sanitary silicone, flax winding, rubber gasket, or a combination of them are used. The video in this article will help you find additional information on this topic.