How to produce fastening pipes: 2 main ways

Even at the design stage of plumbing, heating and sewage systems in a city apartment or a country house, it is necessary to determine which pipe fastening to supporting structures or partitions will be used.

So, you can protect yourself from breakthroughs, depressurization and excessive noise. Let's take a closer look at how to save the family budget by fixing pipes on the walls with your own hands.

Method 1. Closed laying of pipelines

One of the most effective methods that allows you not only to firmly fix the pipelines, but also to disguise them is the hidden laying of engineering networks.

After work, you get the most reliable fastening of plastic pipes (or parts from other materials) that will not spoil the interior of your room. Also, it will release such valuable centimeters along the walls.

The disadvantage of this method is obvious - the high price of work. Indeed, for laying all pipelines, it is necessary to wall the walls and then to seal the resulting channels with mortar, which is quite laborious.

Instructions for the work consists of several consecutive stages:

- Marking on the walls and floors. According to a pre-designed sketch, you need to draw center lines on all the surfaces along which the pipe will run. They will serve as a guide for making installation grooves.

- Shaving. Using the markup, special channels are made in the walls, which are called gates. For this, a special power tool can be used - a wall chaser. But the usual perforator is also perfect. Remember that the laying of some pipelines requires additional use of insulation for pipes, so in advance, worry about the appropriate size of the channels.

Note! The grooves must be laid so that the mounted pipe is not stressed. Otherwise in this place the part may burst, which would entail costly repairs.

- Installation of engineering network. Before fixing the pipe to the wall, it must be enclosed in a shell made of heat-insulating material (polystyrene foam, polyethylene foam, etc.). This is especially important when hidden laying sewer piping PVC.

- Finishing. Before plastering pipes, it is necessary to start up a plumbing, sewage or heating system and make sure that it functions and that there are no leaks.

Method 2. Open pipe laying

This method is more common, less time consuming and costly. In this case, the pipe is fixed to the wall with clamps of various designs.

In total there are two types of fasteners:

- rigid - in this case the pipe fixed in the clamp becomes completely immobile;

- sliding - the part is fixed so as to be able to move along its axis (this makes it possible to avoid distortion at temperature linear deformations).

Fastening of sewer pipes to the wall or ceiling can be done with the help of special - sound-absorbing - clamps. Thanks to them, the structure vibrates less and does not make unpleasant sounds when sewage flows inside it.

When buying a fixing bracket should pay special attention to the choice of its diameter. It is necessary that the fixed pipeline had some mobility in the mount. Otherwise, plumbing or sewage parts may be damaged as a result of linear deformation.

That is why it is impossible to use rigid clamps when sewage pipes are fixed to the ceiling or floor in an unheated room. It is necessary to mount sliding fasteners that can compensate for the resizing of plastic.

Tip! The fastening of the chimney to the wall of the house must also be movable. Exhaust gases entering the chimney have a high temperature, which can lead to a leakage and deterioration of traction. It is advisable to use a special clamp mounting asbestos-cement pipes (galvanized chimney).

Let us dwell on the individual stages of work in more detail.

Training

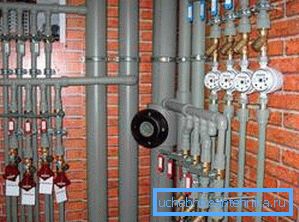

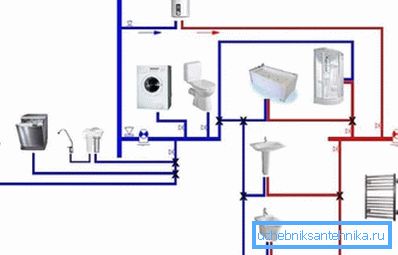

Installation of any complex engineering network, including plumbing and sanitary, begins with the development of the project. In the drawing, the points of joining with sanitary devices, adapters, couplings and other shaped parts, length of pipes, stop valves, accounting equipment, etc. are indicated.

Then markup is made directly on the object. On all surfaces, the route of pipe laying is indicated. The drawn line will serve as a guideline along which the axis of the parts is placed during installation.

After this, the mounting points of the mounting clamps are marked.

In this case, you must consider the following nuances:

- the bracket must be installed at the points where there is a coupling, an adapter, a molded part, or another fitting;

- the distance between adjacent mounting clamps on a straight pipe section should not be more than ten diameters of this part.

Mounting brackets

The plastic pipes should be fixed to the wall with hose clips so that the gap between the surface and the edge of the part is minimal. This allows you to economize on the floor space and prevents damage to utilities during operation.

To equip the sliding mount, insert is inserted into the clamp. Otherwise, its edges are flared (a special device is used for this), which protects the polymer water supply system or sewage system from damage.

The bracket is attached to the wall with screws or dowels. As a rule, accessories are already included in the package.

Pipe installation

As soon as the installation work on the clamps is completed, you can proceed to the next step.

Installation of plastic parts in fasteners, as a rule, does not cause difficulties:

- the pipe is inserted into the clamp;

- the upper part of the fastener is fixed with a latch, stud or bolts.

On a note! Steel pipelines are made in the same way. But in this case it is necessary to provide them with free access for periodic maintenance: removal of foci of corrosion, painting, and checking the tightness of connections. Because of this, by the way, steel pipes are not bricked into concrete walls.

Features of work with metalplastic parts

Improper fixing of pipelines on the wall can lead to an accident. However, to be 100% sure that there are no breakthroughs, you should carefully follow the entire installation procedure.

Here are the basic requirements:

- work with metal-plastic products can be performed at an ambient air temperature above + 10 degrees Celsius;

- if parts are transported or stored at low temperature, they must be heated before operation;

- fixing of metal-plastic plumbing with clamps should be made after the end of the decorative walls;

- in the arrangement of turns in no case should not allow fracture of parts.

Cut the pipes with a hacksaw or special scissors.

It also has its own features:

- The edge of the cut piece may have burrs. To eliminate them, use a file or a special tool.

- After cutting with scissors, the profile of the pipe can become oval. As a result, after fixing the fitting, the tightness can be broken. To align the pipe will help a special calibration tool or a hammer (in the latter case, you must act very carefully).

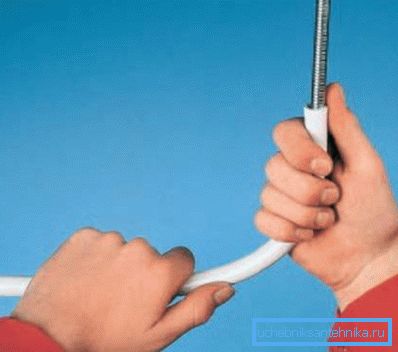

To bend the pipe, especially if you need to achieve a strong bend radius, you also need to use special tools. Internal and external mandrels help. Their use allows you to avoid narrowing the internal diameter of the product and the gust of the pipe in the process.

If the place of the fold is not far from the cut, bend the pipe will help the spring of the desired diameter, which is sold in specialized stores.

Conclusion

There are other ways of fixing pipelines for various functional purposes. For example, the fastening of pipes in tube sheets, which is made by flaring or welding. You can learn more about this by reading the video in this article.