How to seal sewer pipes

The sewage system must be completely sealed. Otherwise, dirt and odors can not be avoided. And how to seal sewer pipes? What are the options, and which one is the most effective? This will be discussed in this article.

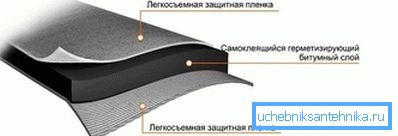

We use tapes for sealing

Many experts will offer to use special self-adhesive tape. Such material is produced both in a usual, and in a foil look.

Self-adhesive tapes have several advantages:

- they are easy to use;

- due to the basis of polyethylene have good performance;

- possess dielectric and anticorrosive properties;

- can be used to seal virtually any pipeline;

- they are used not only when sealing the joints, but also when applying a protective layer on plugs, branches, inserts, etc.

Applying self-adhesive film is performed in the following sequence:

- the foundation is prepared first. The joints (or other areas) are cleaned from dust and dirt. Then the base must be dried;

- when winding the tape it is necessary to ensure its constant tension. At the same time formation of folds and wrinkles is not allowed;

- imposing the material is provided overlap on the previous layer, which must be at least 50%. As a result of such wrapping, each pipe section will be covered with a double layer of tape.

Tip! Self-adhesive film does not tolerate exposure to ultraviolet radiation. For this reason, if the sewer pipes are located in areas exposed to sunlight, it is necessary to provide an additional protective layer.

Silicone Sealant

Most often, a silicone sealant is used to seal the sewer (and others) pipes. This material has excellent adhesion and easily adheres to any smooth surfaces (metal, ceramics, plastic). In addition, silicone sealant easily transfers all the harmful effects of aggressive media and is not afraid of ultraviolet solar radiation.

The composition of the material includes many components, but the main one is synthetic rubber. That it is responsible for the basic quality of the sealant.

For sealing joints and other sections of sewage pipes, two types of silicone sealant are used:

- acid;

- neutral.

The first option is more expensive. It is more resistant to acidic environments, but it can only be used in accordance with the instructions from the manufacturer. The fact is that acid silicone sealant does not fit all surfaces.

Tip! Neutral material can be used when sealing any pipelines and for other purposes. It is considered universal. Only where its use is undesirable is the surface of the metal.

Silicone sealant begins to harden when exposed to air and moisture. Therefore, the tube should be kept tightly closed. The material is used at a temperature of from +5 to +40 degrees. It is simply applied with a thin layer to the desired area. After crystallization, the sealant turns into a substance resembling rubber. Its layer reliably and permanently seals the desired area, without losing its properties over a long service life.

Other options

If you are thinking about how to seal the joints of sewage pipes, then in addition to the two options listed above, there are other equally popular ones.

We list the main ones:

- Epoxy resin. This material is quite widely used in sealing joints.

- Portland cement. Used in the preparation of mixtures for sealing the sewage pipe joints of cast iron.

- Asphalt mastic and petroleum bitumen. It is used to fill the joints and sockets of ceramic pipes.

- Hemp, jute, tar strand. This material is used for various purposes, including for clogging sockets. Most preferred is the use of a combination of hemp or jute ropes and resin impregnation.

- Technical sulfur. It is rarely used, mainly for sealing the joints of cast iron pipes. Before use, technical sulfur is crushed and heated to melting temperature.

There are other materials for sealing. Various mastics and sealants, woven and liquid materials, but they are used much less frequently.

The traditional method of sealing the joints of the socket

For many years, sealing has been used to seal sockets. In this method, the sealing material is clogged up to the depth of the socket to 2/3. The remaining space is filled with cement mortar.

As a sealing material is used resin rope or hemp, or jute rope. For the preparation of the solution is taken cement, Portland cement or asbestos cement. In this case, the cement grade should be at least 400. The mixture is prepared in advance, and water is added just before pouring into the joint of the bell.

The process of sealing the connection socket is as follows:

- pipes center relative to each other;

- then, to a depth of 2/3, the sealing material is placed tightly, while using a special tool - chasing or a caulk;

- then the finished cement mixture is diluted with water and poured into the socket;

In order for the solution to get better and no cracks appear on the surface, a damp cloth is placed in place of the joint. Such sealing is quite laborious, but gives almost one hundred percent guarantee that there is no leakage, especially when using cast iron pipes.

Elimination of leaks

If there is a leak in the sewage system, then it needs to be urgently fixed. Of course, if the pipes are already very worn out, it is better to carry out a complete replacement. But sometimes it does not have the time and money. In this case, some tips from professionals can help seal the gap or fistula:

- If the hole is small, then you can use the old way - to hammer in a small wooden peg. At the same time, it is not worth making it long. A peg sticking inside the pipe can cause blockage.

- If there is free access to the entire surface of the pipe, then an ordinary bandage can be used. The problem area is wrapped with this material, and then the bandage is impregnated with epoxy resin.

- You can use a rubber band, additionally securing it with wire.

It is worth remembering that all these methods are temporary. It is more reliable (and for a longer period of time) to block the fistula by laying a rubber gasket and then fixing it with a repair coupling or collar.

Quite often (especially it concerns products from cast iron or ceramics) cracks appear on the surface of pipes. They may be superficial or solid. In the first case, there is no great danger. Smell and liquid do not leak from the crack. More dangerous are solid cracks.

To cope with this trouble, it is better to use the "cold welding". The work itself will look like this:

- the crack expands, while observing accuracy;

- the problem area is dried and degreased;

- applied pre-mixed, according to the instructions, the adhesive mass, which is allowed to harden.

Cold welding can reliably seal a crack that has appeared. But nevertheless with the replacement of old sewer pipes you should not pull.

We recommend to read:

- soldering polypropylene pipes with their own hands heating;

- how to solder plastic pipes for plumbing.