How to seal the leak in the pipe - tips for beginners

Everyone may be faced with the question of how to seal a leak in a heating pipe or in any other pipeline. Even with the installation technology, there is always the risk of leakage due to mechanical damage to the pipeline or its corrosion. In such situations, you need to be able to fix the leak in a short time, the plumber is unlikely to appear a few minutes after the call.

General recommendations for eliminating leaks

When building sewers, plumbing, heating systems, PVC and polypropylene pipes are most often used. Also quite often found pipes made of cast iron (in old houses), steel and metal-plastic.

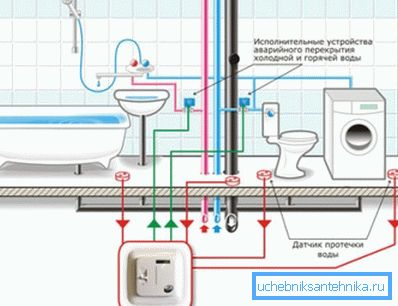

Instructions for eliminating leakage is different for each type of pipeline, but the start of work always looks the same - leakage is localized. For timely notification, you can use the sensor leakage of water.

It is necessary to identify a weak spot and determine where the moisture is leaking from, the way to fix the problem depends on it. So, if the leak source is a socket connection, then it is necessary to check its tightness, but if a fistula appears, then the leak can only be fixed for a while, in the future, the damaged section will need to be replaced. After that, you can already choose a specific method to eliminate the defect.

How to restore the tightness of the pipeline?

All methods can be divided into 2 groups:

- those that allow 100% to restore the pipeline. For example, additional sealing of a socket or filling the gap formed with a sealant;

- measures to temporarily restore system health. As an example, rubber cuffs, “cold welding” compounds and other methods can be given. Need to restore the system for a period of several days to several months, after which you will need to replace the damaged area.

Cast iron pipeline

Despite all the advantages of plastic, metal pipes are still often used for heating and plumbing. In addition, there are also cast iron pipes (used for drainage), in this case the question of how to seal the sewer pipe in the toilet becomes particularly important.

Cast iron is a rather capricious material, it can crack even from a mild impact, besides, leakage can occur due to insufficient tightness of the socket connection.

If the defect is located on a horizontal section, then it is necessary:

- cut the damaged area with a margin of 30 cm to both sides of the leak;

- instead of the cut-out area, a plastic pipe is inserted; when connecting to sections of the cast-iron pipeline, a rubber cuff should be used.

Note! It is necessary to remove the pipeline section carefully, without loosening it. Otherwise, damage to the socket connections is possible.

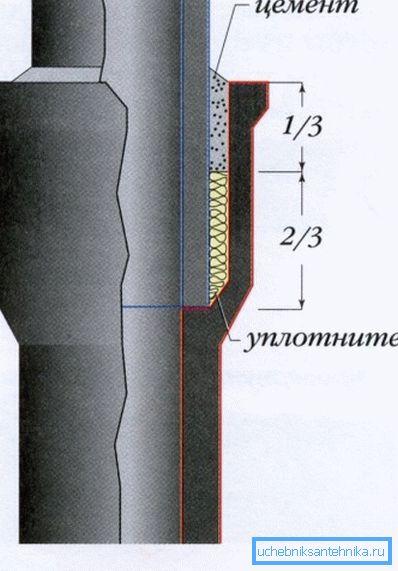

If the water seeps through the socket, then you can restore the tightness with your own hands without changing the pipeline:

- first, the bell must be cleaned, remove the old putty with a chisel and hammer;

- if sulfur or cement was used to fill the socket, then the old material must be removed completely, if lead filling was performed, then it is enough to bare the metal layer;

- after cleaning the bell, a layer of jute or tar-seed tow is filled into it and is poured with cement on top. In the case of lead, the slit is staked with lead cones.

Repair of the steel pipeline

The main danger for steel pipes is corrosion. It is on the drip rust most often found leaks.

The complex of measures for the elimination of the defect depends on the place where the flow is noticed:

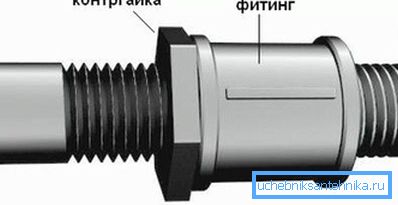

- if the flow is on a flat section, then the replacement of the pipeline section will help to solve the problem. Just as in the case of repairing a cast iron pipe, the damaged section is cut out;

- a thread is cut at the ends of the remaining pipeline; a thread is also cut at both ends of the section of the new pipe;

- a new section is inserted in place of the damaged one; it is connected to the old pipeline with a fitting.

Note! When threaded pipe connection, it is desirable to use winding for greater tightness of the connection.

Repair of the plastic pipeline

When the question arises how to seal the pipes in the toilet, most likely, you will have to deal with PVC pipelines.

The main methods of repair include:

- replacement of the pipeline section (the reason for this may be a long longitudinal crack). The procedure in this case is the same as in the repair of the cast iron pipeline;

- replacement of fashonin. Necessary when the crack socket;

- additional sealing of the socket. In this case, the connection of the pipes is disassembled, carefully cleaned, and to achieve tightness when reconnecting, a rubber sleeve can be used.

When you need to solve the problem of how to seal the pipes in the bathroom, you will most likely have to repair the polypropylene pipe. Damage here is most often associated with exposure to pressure and high temperature coolant.

As for the methods of repair, we can recommend:

- full replacement of the damaged area, it is not always possible to perform. In this case, you will have to resort to temporary measures (discussed below);

- You can try to use the soldering of the pipeline. With the help of a soldering iron, PP chips are fused to the defect site. There is no guarantee that under the action of pressure and temperature such a patch will last for a long time.

Universal pipe repair methods

Sometimes you need to restore the tightness of the pipe at the time, for example, before the visit of the plumber.

In this case, you can use one of the following methods:

- wrap a damaged place with rubber and fasten the cuff with a collar (you can buy such a collar, its price is low);

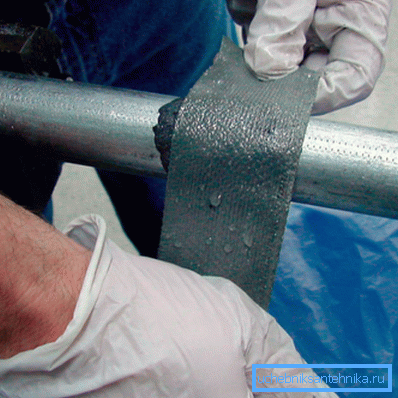

- try to seal the damaged place. For convenience, the fabric is impregnated with an adhesive composition and is wound in several layers around the damaged area;

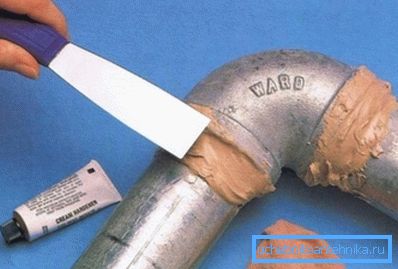

- use cold welding. Such material is sufficient to stretch your hands and press to the leak. It will harden the mixture in about 3-4 hours;

- in a metal pipe of a large diameter, a small fistula can be simply hammered with a wooden chopik;

- if the fistula was formed in a PVC pipe of large diameter, then it is possible to simply screw in a screw greased with oil paint. The hole is pre-drilled to the size of the screw;

These techniques should be considered solely as a temporary measure before replacing the damaged area. Even if the flow has stopped, do not delay the repair.

Summarizing

Leaking pipes is a fairly common occurrence. The work of sewage systems, plumbing and heating is interrelated, so the problems in one of them cause a lot of headaches. Using the proposed methods, it is possible to eliminate the leak fairly quickly, without resorting to the help of specialists.

The video in this article shows an example of emergency repairing leaks in the aqueduct.