How to solder copper pipes

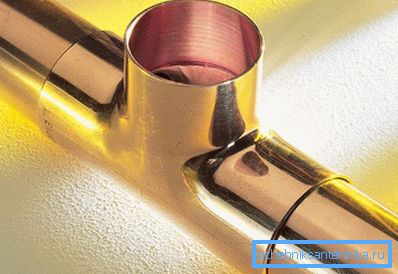

Pipe products made of copper materials and their alloys have not looked like a novelty in our heating systems for a long time; in addition, they are increasingly found today in modern water and gas supply lines of residential buildings and industrial enterprises. These reliable and plastic products are widely used today as critical components of modern air conditioning systems and refrigeration units of various profiles.

All this is quite enough for us to have a desire to learn how to form permanent connections from similar products, or rather, to get acquainted with how to solder copper pipes in the domestic environment. The fact is that the known techniques of joining copper pipes have been used for a long time and imply the introduction of a special molten adhesive compound or solder into the contact zone. What is especially important to know when mastering the process of soldering copper pipes is that reliable welding contact is obtained, as a rule, only in the case when the melting point of the solder itself matters just below the melting point of the welded tubes.

We also note that high-quality and reliable soldering of copper pipes with their own hands will require from the performer special care when working with the products being welded, as well as certain theoretical training.

Advantages of welded copper connections

Not to mention in our article and that the set of evidence that further confirm the undeniable advantages of copper structures obtained by the welded method. Such mentions only increase the ever-growing demand for products, which are distinguished by a whole set of fairly unique properties:

- durability and strength of welded copper products;

- availability and ease of processing copper material;

- the possibility of choosing the conditions for the formation of a welding contact (by adjusting the welding mode).

In addition, the use of the latest welding techniques will allow you to save on such mandatory assembly parts as standard adapters and fittings, which significantly reduces the total cost of manufacturing welded heating pipes.

Copper tube soldering methods and tools used

When conducting special operations related to the welding of billets of various diameters, the following temperature regimes are most often used:

- High-temperature mode with thermal heating of the melt zone up to 900 degrees, used for blanks under significant loads.

- Low-temperature treatment mode, practiced most often in everyday life with a working temperature in the contact zone up to 450 degrees.

For easy fixation of articulated pipes during the soldering process, you may need the following tool:

- The special capture pipe cutter, providing an even cut of the workpiece at the place of its intended welding.

- Chamfer preparation tool (including deburring).

- A special kind of expansion mechanism used to prepare the spike site to a depth approximately equal to the diameter of the welded blanks.

- And, finally, the welding machine itself or the gas torch, directly used for soldering copper joints.

In addition to this, you will certainly need a building thermal dryer, through which it will be possible to heat the junction points of the blanks up to 650 degrees (used mainly when working with low-melting solders).

The presence in the current toolkit of such a heating-welding machine will allow its owner to easily adjust the temperature in the welding zone, as well as maintain it at an optimal level. In addition, a wide range of interchangeable nozzles that are included in the working set of the welding device provides you with the opportunity to direct a stream of heated air to any place convenient for you.

Materials used in brazing copper pieces

Before soldering the heating pipes with their own hands, any performer is simply obliged to thoroughly familiarize himself with the working materials used as thermal solders. In addition, he certainly should be aware that all these materials according to the characteristics of refractoriness are divided into hard and soft solders.

Solders

The so-called solders of high refractoriness outwardly resemble elongated rods of an arbitrary profile and are usually used when heating the metal in the soldering zone to the maximum possible temperature (up to 900 degrees Celsius). Such temperatures provide high quality and reliable soldered contact.

Tip! Such soldering materials are mainly used in repair and restoration work carried out on responsible supply lines or in the repair of industrial air conditioners and special refrigeration equipment.

The most typical representatives of soldering solders of this class include self-fluxing copper-phosphorus compositions, equipped with a variety of additives (such as Cu94 P6 and Cu92 P6 Ag2). The 6% silver or phosphorus, which is almost imperceptible to the eye, will allow you to lower the melting point of such a solder up to 750 degrees. And this is assuming that the actual expansion rates of the materials used almost correspond exactly to those of copper, which makes it possible to obtain a strong and reliable connection.

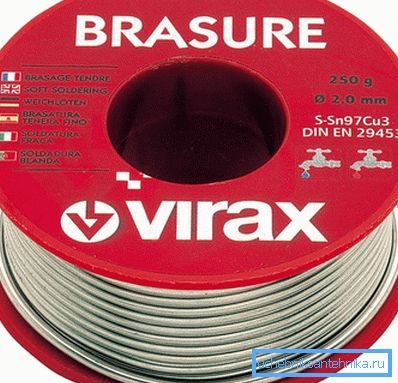

Solders, commonly called “soft”, got their name because they are used in the process of low-temperature processing of copper pipes produced in living conditions. They are made, as a rule, in the form of rather thin wires and are developed on the basis of such popular chemicals as lead, tin, zinc or their alloys known to all of us.

Fluxes

In order to simplify the procedure for soldering copper pipes with their own hands, special paste-like or even liquid compositions are often used (they are also called fluxes). It is important to note that often the success or failure of an operation can often depend on the proper selection of one or another flux.

Like solders, the materials we are considering are also conventionally divided into low-temperature reagents (up to 450 degrees) and high-temperature chemical components used for soldering above 450 degrees.

Such chemical compositions are used for the following purposes:

- contribute to the purification of the soldering zone from harmful oxides;

- protect the working area from the ingress of oxygen, which is always contained in the environment;

- form favorable conditions for a uniform distribution of the soldering composition at the soldering points;

- improve the quality of adhesion of products with solder.

In the process of work, the solder, heated to the desired temperature, evenly spreads in parts of the parts to be soldered, thus forming a reliable connection. After the soldering contact cools down from the treatment area, all excess flux is simply removed.

Video

This video is devoted to soldering pipes with soft solder: