How to solder pipes made of polymeric materials: practical

Planned a major overhaul with the replacement of plumbing and heating systems? In this case, get ready for serious material waste or learn how to solder PVC pipes yourself.

The topic of self-assembly of pipelines is not accidental, since the price of services of professional plumbers is quite comparable with the cost of the materials used. Of course, doing all the work yourself can save money and gain useful experience that will probably come in handy someday.

So, let's try to figure out how to properly solder the pipes on our own, but first we will select the appropriate materials and equipment.

Selection of tools and materials for pipeline assembly

Before soldering propylene pipes, it is necessary to prepare all the necessary accessories.

For work, you will need a manual soldering iron, a special secateur, rags and a degreaser, and, of course, materials from which we will do the plumbing with our own hands:

- Polypropylene pipes and fittings are the materials from which most modern water and heating systems are assembled.. The choice of such materials is not accidental, since it is polypropylene products that can be soldered to achieve a vicious, reliable and durable connection that does not require regular maintenance and repair.

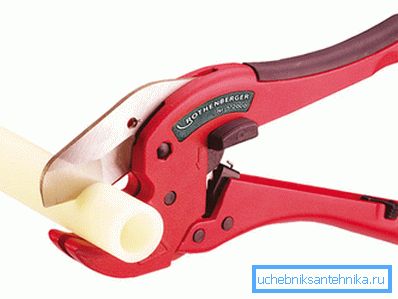

- Special pruner needed to cut the pipe at an angle of 90 degrees. This is an important condition for the preparation of materials for soldering, since only when using a pruner you can be sure that the pipe will become even and there will be no gap between it and the fitting.

- A degreaser and lint-free cloth will be required to wipe the pipe and fitting before heating.. Such preparation of plastic parts ensures optimum quality and durability of the compound.

- A soldering iron is needed to heat the pipe and the inner surface of plastic fittings to the melting temperature. There is a wide range of such devices on the market, so the choice of a suitable model should be discussed in more detail.

Choosing a soldering iron

Many novice plumbers are faced with the question of how to solder plastic pipes with a soldering iron with a regulator. Meanwhile, there is nothing difficult in this matter, since by its construction the device for mounting polypropylene is similar to a conventional iron.

As well as in the construction of a domestic iron, two main assemblies are used in the soldering iron, namely, a heating element and a temperature controller. The presence of a temperature controller on the instrument indicates that the soldering iron is universal and adapted to work with different types of polymeric materials.

By rotating the regulator, you can select the temperature of the heating element that melts the plastic to the desired degree, but no more and no less.

Choosing a tool, you need to pay attention to its configuration, sizes and power. The tool should be hand-held, mobile, and as compact as possible.

Working in the bathroom or in the kitchen, it is not always possible to settle down with maximum convenience, sometimes you have to work in cramped circumstances, and in this case tools with compact dimensions and convenient form will be useful. The power of the selected tool must be at least 1 KW.

An integral component of the soldering iron is a set of nozzles (sleeves) of different diameters.

On average, a complete set of a standard soldering iron includes a set of nozzles of the most popular diameters. For example, the 20th nozzle is suitable for the cross section o1 / 2 ?, 25th - corresponds to the cross section of 3/4? etc. In the extreme case, if the soldering iron is purchased, but there is no nozzle of the required size, it can be purchased.

Important: You can solder pipes with a hand soldering iron, the diameter of which does not exceed 63 mm, which is equivalent to a cross section of 2 ?. If a larger diameter pipe is to be made, a welding machine is required.

So, after we decide on the parameters of the main tools and materials, consider how to properly solder plastic pipes.

Pipeline assembly technology

Installation instructions are simple, and therefore, having bought everything you need, feel free to get to work.

Installation is performed as follows:

- At the initial stage we prepare a soldering iron. We select a pair of nozzles in accordance with the diameter with which to work. On the heating element of the tool nozzle (sleeve) is better to install as close as possible to the edge. Thus, you will provide greater ease of installation work. In terms of heat intensity, the location of the nozzles does not matter.

Important: As work progresses, carbon deposits from the burned-out plastic residues will be collected on the sleeves, but metal deposits cannot be removed. The fact is that the sleeves have a Teflon coating that is not recommended to be scratched, and therefore it is recommended to scrape off the carbon deposits only with wooden scrapers or rags. To clean the sleeves, the soldering iron must be heated to operating temperature.

- At the next stage, the pipe from one of the ends is cut with a special shears. If the pipe has aluminum reinforcement, check that the edge was cut exactly. If the cut is uneven, there is a possibility that the solder joint will be leaking.

Important: For better quality and reliability of the connection, we use polypropylene pipes with a red stripe on the side. They have foil reinforcement, and therefore are designed for greater pressure and high temperature of the transported medium. Of course, such pipes are somewhat more expensive than regular polypropylene, but this difference is offset by the durability of the finished result.

- Next, we clean the parts of dirt by wiping with a degreaser, and mark the welded area with a pencil. If you solder the pipes reinforced with aluminum, the metal layer is scraped off the area where the welding will be carried out. Fiberglass reinforced parts are not trimmed.

- We turn on the soldering iron and set the required temperature using the regulator, on average, +260 ° С is enough. The tool heats up quickly, therefore, you can start working in 5 minutes.

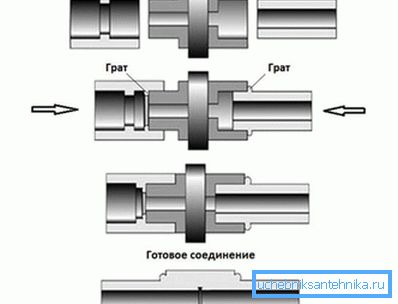

- Further, on the one side of the liner we attach the pipe, and on the other hand the fitting. We count to 15, after which we separate the parts from the nozzle. Preheated parts immediately connect - fitting worn on the pipe until it stops. It is important to make sure that the fitting is in the right position, because if it is standing incorrectly, after the plastic has cooled, it will be impossible to turn it.

Tip: Considering the above, you need to work with a soldering iron together. One novice installer must hold the tool in the desired position, while the other must attach to the sleeves elements heated for installation. Given the difficulty of soldering polypropylene pipes on weight, first practice on the desktop, soldering a test piece of pipe with a test fitting.

- After the soldering of the node is carried out, we wait about 2 minutes. This time will be enough to cool the plastic and gain the required strength. During these two minutes, it is not recommended to stir the connection.

What needs to be considered when carrying out installation works

- If the question is whether it is possible to solder metal-plastic pipes made of polypropylene, we can confidently answer - you can! The PERT-AL-PERT connection is carried out with a regular soldering iron, but with special fittings and with prior scraping of the foil layer.

- When installing, you must take into account the order of priority. For example, all the small parts can be soldered on weight, and only then boil the assembled units to the main pipe.

- Cranes are welded in the closed state.

- Before installation, the plugs are heated in 2 steps, and after that the pipe heats up.

- In some cases, individual elements of the plumbing are collapsible. For this soldered screw connection. This is done in hard-to-reach areas where the presence of a threaded connection will simplify assembly.

- If a mistake was made during installation, do not attempt to digest a damaged fitting, as it is to be replaced.

Conclusion

Now you know how to solder the propylene pipes and save money when replacing the old water supply system. Are there any questions that need clarification? In this case, more useful information can be found by watching the video in this article.