How to solder plastic pipes: instructions

Soldering plastic pipes is performed by a special soldering iron. And although this process is much easier than welding metal pipes, you still need to acquire the skill. Having your own tool and gaining knowledge, you can independently perform the installation of water supply or heating.

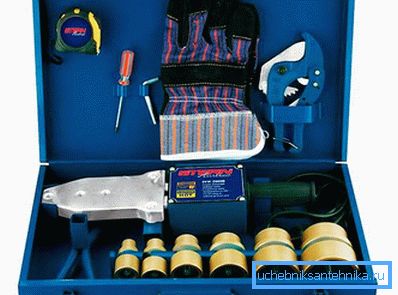

Which tool to choose

For soldering plastic pipes use a soldering iron with nozzles. Each nozzle corresponds to the diameter of the pipe and fitting. The device consists of a stand and a heating element. Some models have a temperature controller. If you are planning a single type of pipe soldering, then buying a soldering iron, you should not overpay for the presence of a regulator. Simply select the model designed for the desired soldering material. Well, if you count on a variety of work in the future using different types of pipes, then you have to fork out for a more expensive device.

Tip! The heating indicators and switches are installed on the body of the soldering iron. For convenience, the soldering iron stand has attachments for nozzles. At the time of soldering, they will always be at your fingertips. Powered soldering iron from connecting to a regular outlet. All work can be done on weight or permanently.

Stages of work

Initially, we immediately designate that the soldering is performed at a temperature of 260aboutC, and polyethylene - 220aboutC. When making the pipeline, calculate all the connections so that most of them can be soldered on a stationary soldering iron. And let it be necessary to make only a few convenient joints with the help of which you will connect the blanks into a common pipeline.

- Measure out and cut the necessary pieces of pipe with special scissors. Prepare fittings of the appropriate size.

- Install the soldering iron with stand on the table. On the heating element, install the nozzles under the appropriate diameter of the pipe and fitting. On the stand, fasten the nozzles in order of their application. In this position it will be more convenient to pick them up during work.

- Turn on the soldering iron in the outlet and set the temperature regulator corresponding to the pipe material. Warming up the soldering iron lasts about 20 minutes, the LED indicator will inform you about its readiness.

- Measure the depth of the fitting and mark the same distance on the edge of the pipe. This procedure will prevent the preheated pipe from being squeezed into the fitting. In the future, gaining experience, you will feel the emphasis in the wall of the fitting, and such marks will no longer be necessary.

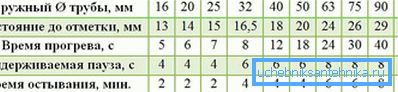

- Remove the marked area on the pipe and the inside of the fitting with alcohol or acetone. At the same time, install the pipe and fitting into the heated soldering iron tips for warming up. Experienced workers determine the warm-up time visually. A novice wizard is better to use the warm-up table.

- Preheat the pipe evenly, without turning, insert it into the heated fitting up to the mark made by you. Pause to solder the plastic and leave the compound until it cools. In the correct connection at the place of welding get a plastic ring.

Before you start, watch the video and practice on pieces of pipe. This will help you in the initial stage of work.

Useful tips

In order for the connections to be strong, and the tool to work properly, let's consider some of the rules used in the work.

- After each soldering of a separate element, molten plastic may remain on the soldering iron nozzle. It must be removed with a wooden scraper. Do not use metal scrapers for cleaning, otherwise you will damage the Teflon coating of the nozzle. This will cause nagar and sticking of the nozzle to the plastic part.

- To better enter the pipe into the fitting, make a facet on the edge of the pipe with a face picker. In the reinforced pipe before soldering, remove the aluminum foil to the mark on the pipe. Only after that start heating up the parts. If in a reinforced pipe the foil is not on top, but in the middle of the plastic layer, then it is not necessary to remove it.

- Soldering plastic pipes should not be performed at a negative temperature. Carefully dock with the main riser or taps. With a poor connection, it is better to cut and solder a new one. Fitting with a threaded connection when twisting seal FUM tape.

A well-welded plastic pipe will never flow at the joint and will last for many years. As manufacturers promise, the service life of a plastic pipeline is at least 50 years.

Video

Through watching this video, you will learn how to solder polypropylene pipes yourself, what tools are needed for this: