How to solder plastic pipes

For the installation of modern piping system used materials made of polypropylene. Its more common name is plastic. If earlier only hard metal materials were used in construction, now they are successfully replaced by better plastic. In this article we will explain how to solder plastic pipes.

Material Features

From the very beginning of its appearance, polypropylene took a leading position in construction. At the optimum cost, the plastic has undeniable advantages:

- Not subject to destruction, rusting, corrosion.

- Safe for the environment.

- The use of plastic pipes in residential areas does not cause an allergic reaction in humans.

- Plastic pipes are resistant to harmful bacteria and microorganisms.

- The ability to carry both low and high temperature in the room.

- The material is quite light and easy to transport.

- A simple way to use in domestic conditions.

- At installation special skills and abilities are not required.

- With respect to the mode of operation can be used for half a century.

What are plastic pipes

The material for the manufacture of plastic pipes is polypropylene polymer. This material can be used for the construction of pipes of any type of water supply. It is able to withstand temperatures of up to 110 degrees.

Pipes are resistant to low temperatures and do not collapse when they freeze.

To date, there are three main types of plastic pipes:

- Pipes used for cold water supply.

- Pipes used in different types of water supply.

- Plastic pipes with reinforced base. They are used for the manufacture of heating systems.

For domestic use, it is recommended to use pipes with a diameter of 2 cm to 3.2 cm. When purchasing pipes, you should pay attention to their diameter, according to which you should purchase equipment for soldering.

Work with plastic pipes

Independent installation of the water supply system involves the following stages of work:

- Surface preparation.

- The installation of the pipeline.

- Pipe connection.

- Soldering plastic pipes with their own hands.

Self-brazing

For independent connection of the water supply system in the building it is necessary to use soldering technology to connect the parts of the pipes:

- It is necessary to pre-draw a plan of the water supply system in the building, indicating the location of the central riser and the main sanitary units.

- Pipes should be soldered in the direction from the plumbing fixtures to the riser.

- Works should be carried out using special equipment.

Soldering tools

To independently solder plastic pipes, you need the following materials:

- Soldering iron - the main device. With it, soldering is carried out.

- Marker.

- Scissors for pipes.

- Level.

- Roulette.

- Sealant.

- Gas keys (you need to purchase equipment of different sizes).

- Knife.

- In the absence of special scissors, you can use a hacksaw for metal.

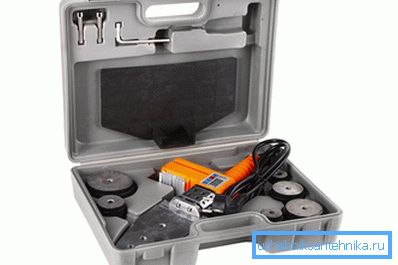

Choice of a soldering iron

Soldering iron is the main tool for work. A professional device is usually expensive, but you can rent it.

Soldering iron for home use has some limitations in the configuration, but has an acceptable cost.

- When choosing a soldering iron, pay attention to its power. So, for welding plastic pipes with a diameter of 1.6 cm to 6.3 cm, equipment with a capacity of 1.2 kW is suitable. A more powerful device (from 1.2 kW and above) is used for professional construction work.

- For the implementation of the work, special nozzles for a soldering iron are used. They provide uniform heating of the device. To improve the quality of work and increase the service life, a special non-stick coating is applied to the surface of the nozzles. Six nozzles with different diameters are provided as standard.

- Tip on the technology of application nozzles. The most convenient is the possibility of simultaneous use of three elements at once. This will significantly reduce the work time. A soldering iron, the complete set of which implies the simultaneous use of only one nozzle, when changing it, must first restore the initial temperature. Only then you can use the nozzle of a different diameter.

- The design of the soldering iron must be implemented to control the heating temperature. Modern soldering irons have electronic control that allows you to adjust the temperature with maximum accuracy. If your soldering iron does not have a temperature control function, you need to purchase a special thermometer.

Instructions for using the device

During the procedure, it is recommended to follow the basic rules for using the device:

- The average heating temperature should be 260 degrees. If the heating temperature is much lower, the pipe joint strength will not be achieved. At temperatures above 260 degrees, the material can simply melt and solder will be impossible.

- Work should be carried out only on flat surfaces.

- Using gas keys on the soldering iron, you must install the required nozzles.

- Separate sections of pipes are recommended to connect on a flat surface. Only after the end of the soldering can they be installed on the wall.

- After switching on the device, wait for an acceptable heating temperature. It is usually reached in 15 minutes.

- Do not unplug the appliance during operation.

Tip! If during work on the nozzle of the soldering iron was extra plastic, it should be removed immediately. This can be done using canvas canvas. It is unacceptable to remove residual polypropylene from the cooled nozzle.

Soldering process

So, how to solder plastic pipes yourself:

- Prepare a soldering iron for work and install the necessary nozzle. Adjust the optimal temperature parameters of the device and wait for it to heat up.

- Using special scissors or a hacksaw, we cut the required length of the pipe. Work is performed at right angles.

- At the prepared nozzle soldering iron should be installed at the same time the pipe and fitting.

- The heating time of the pipe depends on its diameter. Thus, equipment with a large diameter should warm up much longer than small pipes.

- After uniform heating, the pipes and fittings should be removed from the device.

- A heated pipe should be inserted into the fitting. Parts must be held for several minutes. Typically, the time of the melting procedure on devices with different diameters is indicated in the technical passport of the soldering equipment.

Tip! Remember that if a mistake was made during soldering, it could damage the entire piping system. To eliminate it, it is necessary to cut off the area with the defect and reconnect with a soldering iron.

Video

More soldering procedure is shown in the following video: