How to weld a profile pipe

Profile pipes are most often used for the manufacture of metal structures. They make the most reliable and durable structures, regardless of their complexity. Do-it-yourself welding of shaped pipes is a difficult and responsible procedure; to perform work at a good level will require skills in working with welding - arc or gas.

Profile pipes from selected grades have become more likely to undergo welding than their plastic counterparts. The popularity of metal products is due to several factors:

- resistance to deformation effects;

- relative ease. A running meter of shaped pipes is lighter in weight than the same amount of all-metal products;

- dimensions. Pipe dimensions are standardized, which allows to simplify the process of creating complex structures;

- relative ease of installation. Subject to the skills of welding, pipes are easy to weld, because they have smooth edges;

- durability;

- reliability;

- availability.

Allocate profile tubes of the following types:

- electrowelded;

- cold-deformed electrowelded;

- cold formed seamless;

- hot rolled seamless.

The cross section of each type of pipe is different. So, for example, an electrowelded method of manufacturing allows you to make pipes with a wall thickness of up to 5 mm and a total thickness of up to 10 cm. The electrowelded method is chosen if you need to make pipes with a wall thickness of 1-5 mm and an outer dimension of 1-10 cm.

The method of hot deformation is applied to pipes with an outside size of 6-18 cm and a wall thickness of 4-14 mm. But they deform the products in a cold way to obtain a wall thickness of 1 to 8 mm and an outer size of 1-12 cm. In general, profile pipes are valued not because of the shape of the section, but because of their high strength and economy, which these products are not deprived of.

Steel for profiled pipes is selected only the best. Among many varieties of this material preference is given to low-alloy and carbon. Manufacturers make such products are also made of stainless steel, but they are not so popular. Welding of profile pipes can be carried out only by common types of welding:

- contact;

- electric arc;

- gas.

Now we will consider each of the presented technologies in more detail.

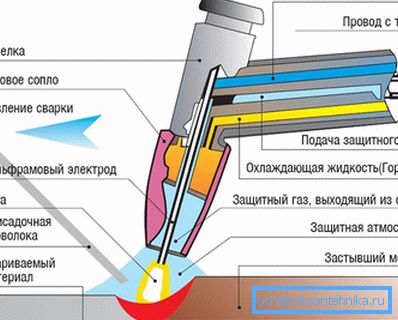

Arc welding

You have the opportunity to create any design, as it is possible to weld a profile pipe at any angle. With this technology, it is easy to weld metal pipes with overlap and T-joints.

Tip! Experienced welders recommend making the seam on the profile pipes in the lower position, but if you need to connect these products in hard-to-reach places, you can use other types.

Mode selection

It is recommended to choose the mode of welding work according to the following indicators:

- Current strength

- Polarity and kind of current.

- The speed of work performed (the movement of the electrode on the welded products).

- The diameter of the electrode.

- Voltage on the arc.

- The slope of the electrode.

The strength of the current depends on the electrodes used. To maximize the efficiency of the connection, you must try to achieve the highest rate of current strength. Remember that moving beyond the allowed edge will reduce the quality of the seam.

Tip! How to cook a profile pipe so that the metal does not sag? It's simple - control the amount of additives, while the edges of the products must be given time to reflow.

Those who use welding for such products for the first time want to recommend working with thin-walled pipes in reverse polarity. Before working with thick-walled metal structures, you must first prepare the edges.

For high-quality fusion products need to cut them. Correctly and qualitatively processed metal edges will not allow tension to grow, but it will be possible to impose several seams. It is necessary to carve the edges under 25-50 degrees. It is possible to choose a more accurate value after determining with the technology of welding products and their thickness.

Electrodes, there are two types - melting and non-melting. When working with the latter, filler wire is required. Such a tandem provides an almost perfect combination of products and, moreover, is very durable. However, such electrodes can be used only in cases when the elements to be joined have the same diameter.

What kind of electrodes to weld the profile pipe, if the welded pipes have the same diameter? The answer is simple: choose non-consumable electrodes, and in all other situations - the second. The diameter of the electrodes is determined by the thickness of the walls of the welded elements. It is also important to choose the strength of the current so as not to burn them when working with thin shaped pipes.

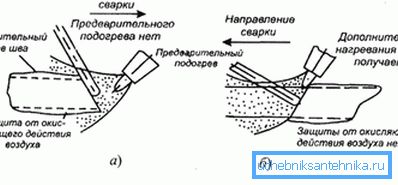

Gas welding

How to cook a profile pipe using this technology? Gas welding is rarely used to connect such products, as it is not possible to weld properly due to the poor mechanical properties of the resulting weld. This technology involves heating the edges of the shaped tubes with an oxy-flame flame, after which you can fill the gap formed between the two elements.

Gas welding, should be carried out on the prepared edges, which are cleaned of dirt and cut. A detailed video about this technology will be a good example.

To cook by gas welding, you need oxygen and acetylene. For the work you need additional material - welding wire and flux.

The first material should be the same as the welded section pipe, and the second is necessary to reduce the degree of oxidation of the metal. The latter component creates a thin film on the edges of the tubes, which helps protect the metal.

Tip! To work by gas welding at home you need to have experience. Such equipment is explosive!

Gas welding can be carried out:

- From left to right. When choosing such a technology, gas consumption is minimized, and the work is done faster. Applying a seam according to this principle involves the use of an additive directly behind the burner itself, which allows welding thick-walled pipes.

- From right to left. This technology is used for thin-walled profiles, because it allows you to get a neat seam. Here the additive is applied before the burner.

contact welding

The connection of products can be carried out in any climate change. It is contact welding that provides reliable and high-quality weld, but only specialists can work on this technology. The principle of resistance welding: with the help of current, the edges of the profile products are welded. The connection of metal products occurs without any additives.

Profile pipes are reliable and durable products. With high-quality welding, the construction of them will last several decades. We considered all possible technologies for the connection of specialized products.