How to weld pipes by manual arc welding: we study the

In the construction of pipelines, as well as in the household, several ways of connecting pipes are used. But among the variety, welding is most often used. Such popularity is explained by the fact that thanks to this method, a practically monolithic compound is obtained, which has high strength characteristics. In addition, a high level of tightness is achieved.

Basic welding methods

Gas welding

All methods of this compound can be divided into two groups:

- Gas welding using pressure;

- Gas welding, which uses heat, that is, melting.

In turn, gas welding using pressure is also divided into the following subspecies:

- Contact welding;

- Connection by friction;

- Gas press welding;

- Cold welding;

- Termite compound.

Tip! Cold type gas welding for nozzles is used when working with those elements that are made of non-ferrous metals and are distinguished by plasticity (i.e., copper or aluminum). The principle of this type of connection is the joint plastic deformation of the material in the place where its compounds are strongly compressed.

Thermal welding:

- Welding pipes manual arc welding;

- Gas welding.

The price for different methods of this type of compound differs insignificantly; therefore, it cannot become a decisive criterion when choosing one or another method.

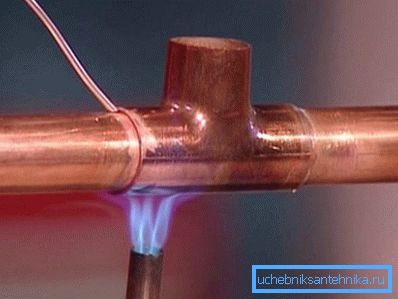

Gas welding technology

The first stage of work is the preparation of pipes for welding. Here the edges of the welded pipes in the gas-oxygen flame supplied from the apparatus are heated. The gap between the edges is uniformly filled with the molten metal of the bar used.

It should be noted that the seam, which is obtained as a result of this method, has lower mechanical properties as compared to the seam obtained as a result of the electric arc method.

The method of gas welding is preferable to use if the work is carried out with pipes of small thickness (up to 3.5 mm). A very important step before starting work is to prepare the edges of the pipes for welding.

Materials and means used in gas welding

It is worth noting that this method uses a variety of devices for welding pipes.

To properly conduct the process of gas welding must be used:

- Oxygen. Necessary to maintain stable combustion and high temperature.

- Acetylene, which is the basis for burning.

Tip! In some cases, it is possible to replace acetylene with other combustible gases. The main criterion is the temperature of the burner flame, which should be 2 times higher than the temperature at which the metal is melted. Propane and methane are often used.

In addition to these two gases are also needed:

- Welding wire, which acts as a filler material to fill the seam. The chemical composition of the selected wire should be as close as possible to the composition of the metal.

- Fluxes. This material is responsible for reducing the degree of oxidizability of materials during welding. The flux can be in the form of a powder or paste. When heated, this substance floats to the top, thereby forming a protective film that most prevents air molecules from penetrating into the metal.

Welding technique

DIY gas welding has a clear sequence:

- Cleaning the metal surface from contamination;

- Preparation of connections for the connection, namely the mechanical processing of edges. If thin-walled pipes are welded, then such processing is not necessary.

Separately, it is worth noting that the modern technology of gas welding pipes uses two different ways to perform:

- Right. In this case, the work is carried out from left to right. The flame of the burner is directed to the seam area, and the filler rod moves smoothly following the gas burner. In this method, the performance is increased by almost a quarter, the gas consumption is reduced. This type of compound is used with a wall thickness of pipes from 5 mm.

- Left. Here, the direction of movement is from left to right, the burner flame is directed to the not yet welded edges of the nozzles, and the bar is moved in front of the burner. Thus, welding of pipes in hard-to-reach places becomes available. In addition, the presentation of the product manufactured in this way is significantly higher.

Edging

Preparation of pipes for welding is an important preparatory stage on which the quality of future work depends. The preparation includes cutting edges. Remember that this stage of work allows stitching in layers, each of them has a small section.

When cutting edges improves the structure of the weld itself, which contributes to reducing the stress in the metal. The cutting angle can range from 25 to 50 degrees. The choice of a specific value depends on the thickness of the metal, as well as on the chosen welding method, type of connection.

Welding of the root of the pipe seam should be performed by a professional or under his strict guidance. Instructions for the implementation of this stage is considered to be quite complicated, therefore, in most cases, it is given to specialists.

Welding battery from pipes

Let's figure out how to weld the battery out of pipes at home, if all the necessary tools and materials are at hand.

To do this, the following sequence:

- The pipe is cut to the required length.

- The number of sections depends on your desire.

- The marking under jumpers is done. For them, a pipe is placed with a diameter of 25 mm, length 10 cm.

- Now from a steel sheet stubs are cut.

- Holes for bridges are cut through, central pipes are cut through, and the top, bottom ones are only from the inside.

- The battery is dismounted with jumpers, tacks are made for fixation.

- In the vertical position all the joints are boiled.

Conclusion

Welding of pipes is the most optimal method for a hermetic connection, whether it be works on the construction of a new pipeline or the installation of pipes of a sewage system or heating system at home.

In the presented video in this article you will find additional information on this topic.