How to weld pipes made of metal and plastic

Today, many technologies have become available, for example, welding steel pipes will not become an insurmountable obstacle during repairs. Practically any person, having acquired the necessary equipment, can perform such work. In this article we will tell about the welding of various materials.

Hardware

Of course, the most difficult process is the welding of metal pipes. Therefore, we will introduce you to him first. In fact, the scope of work will practically not differ, depending on the metal, so we will give you general recommendations.

Electrode selection

In order for welding of stainless steel or other types of rolled metal products to be successful, it is necessary to select a suitable electrode. All the widest variety of these products are divided into two groups: with a melting and non-consumable base.

In addition, there is a classification by type of coverage:

- Pulp (grade C). Used primarily for vertical and circumferential seams on large-sized products.

- Rutile acid (brand RA). The main feature - the formed slag can be removed upon completion of work.

- Rutile (brand R). Characterized by the ability to easily and easily set them on fire a second time. Also of note is the good degree of slag impact.

- Rutile cellulose (brand RC). It is recommended for use in difficult situations, for example, if welding of copper pipes along a vertical seam from top to bottom is expected.

Interesting: it is this type that allows you to create beautiful and even seams, so if this aspect is important to you, then it is better to give preference to it.

- Basic coating (grade B). They are the most qualitative type, which allows you to create seams with the highest characteristics (excellent viscosity, minimal probability of cracking, etc.). Recommended for use in extreme conditions (low temperatures, exercise, etc.).

Of course, the best option is the last variety, but its price is too high. Therefore, if it is not assumed that there are high loads on the product being welded, then using it is not entirely appropriate.

Surface preparation

Before you begin the main front of work, you need to make some preliminary manipulations. In particular, the instruction requires to check the state of the surface.

To be more precise, you must evaluate how compliant the GOST products to be connected are, namely:

- The presence of a certificate.

- Correspondence of geometric dimensions (wall thickness, length, etc.).

- The absence of any deformations.

- Compliance by chemical composition.

Convinced of the satisfactory quality of the material, it is necessary to clean it of oil, dirt and rust (if any). You also need to make sure the perpendicularity of the end. If the angle is not straight, you will need to align it.

Tip: if there is a discrepancy between the shape of the bevel, then this problem can be solved with the help of a grinding machine or a face picker.

If we are talking about pipes of large size, then the processing will most likely require a milling machine. An alternative option is air plasma cutting. Welding of aluminum pipes (or any other) is possible only after a thorough preparation stage.

Welding

When the source material is prepared, you can proceed to the main work front.

Consider the sequence of works:

- We have tacks around the entire circumference, and evenly. Their number depends on the diameter, for example, four tacks will suffice for a pipe of no more than 300 mm. In addition, each of them should be 5 cm long and 3-4 mm high.

- The first welding layer should receive a height of 3.5-4 mm. To achieve this, you should use electrodes of small diameter (no more than 4 mm).

The next layer should already be done with larger electrodes.

Everything is done like this:

- We divide the joint of welded pipes into 4 parts (visually, but better with chalk or other available materials).

- Then we weld the first two sectors, which are located at the top of the pipe.

- Then the product is turned over and the processing of the remaining sectors is performed.

- Then it is turned over again and put the second layer on the first two sectors.

- Finish the procedure by applying the second layer on the last two sectors.

- If there is a need to create a third layer of the seam, then it should be done in one direction.

Plastic

Today in the private sphere are rarely used metal products, preferring to work with plastic. It is easier, cheaper, more durable and easier to work with. Therefore, the question of how to weld plastic pipes is currently very relevant.

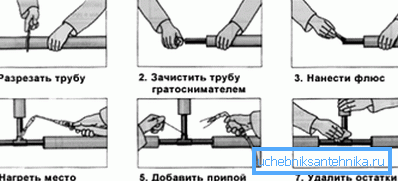

This procedure is performed like this:

- In the butt welding machine insert the appropriate heating nozzle (depending on the type and size of the connected elements).

- After that, the corresponding segments are cut. The resulting edges must be carefully sharpened. If welding your own PVC pipes is done by you for the first time, then it is best to grind at a slight angle - in this case it will be easier to succeed.

- Then we do a fitting and mark the places of connections with a marker. It is necessary to prevent mistakes in the future.

- Degrease the surface.

- We warm up a fitting for welding of pipes. After that we put on the prepared segments on it.

- After waiting some time (depending on the wall thickness), we remove the parts to be connected from the nozzle and fix it carefully. It should not be allowed to rotate. The resulting suture should be fixed.

Conclusion

This is the time to summarize our story, but we have prepared for you an additional portion of knowledge. In the presented video in this article you will find additional information on this topic. After viewing this video, you will certainly be able to understand all the nuances.